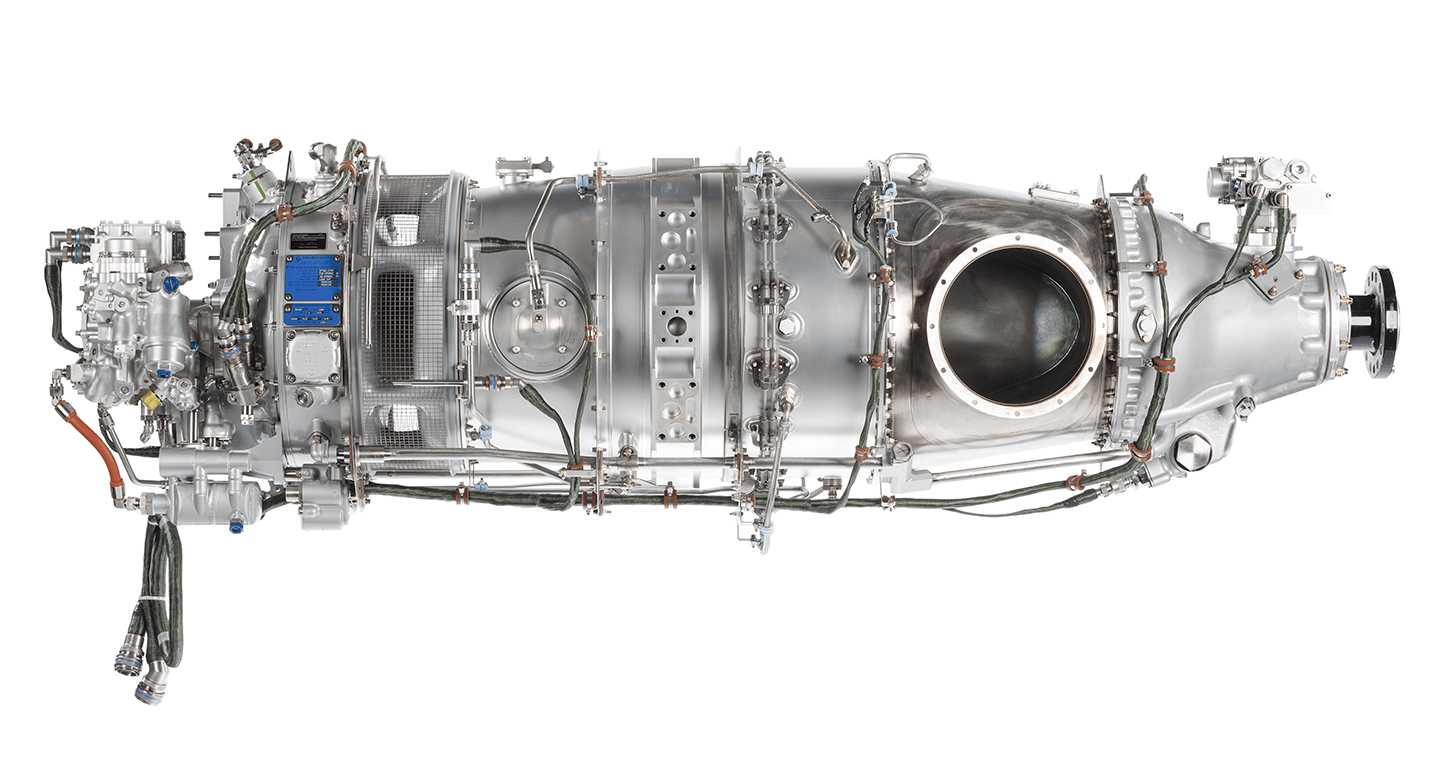

Pratt & Whitney introduced the JT8D to commercial aviation in 1964 with the inaugural flight of Boeing's 727-100 aircraft.

The JT8D engine has proven itself to be a highly durable and reliable engine, having completed more than 673 million dependable flying hours since entering service. Once deemed the workhorse of the industry, more than 14,750 JT8D engines have flown. Today, there are 2,400 engines still in use.

The eight models that make up the JT8D family cover a thrust range from 14,000 to 17,000 pounds. The JT8D-200 series, which entered service in 1980, offers 18,500 to 21,700 pounds of thrust, and is the exclusive power for the popular MD-80 series aircraft. The JT8D-200 builds on the family's excellent reliability and low maintenance costs while meeting noise and emissions regulations.

Pratt & Whitney has developed a new low-emissions combustion system, or E-Kit, that is FAR 25-certified to ensure the JT8D-200 engine stays current with environmental regulations. The E-Kit reduces JT8D-200 engine NOx emissions by 25 percent and exceeds all ICAO standards for new production engines.

Yes, we retrofit legacy systems (e.g., GE Frame 5, Siemens V94.2) with modern digital controllers, typically completing hardware integration within 4-8 weeks. Software migration requires additional validation time.

We recommend annual performance testing under ISO 3977-2 standards. Critical applications (e.g., offshore platforms) may require semi-annual tests with emissions compliance checks.

All rad-hard devices (e.g., FPGA, ADC) are QML Class V certified under MIL-PRF-38535 and tested to MIL-STD-883 Method 1019 for SEU tolerance. Full qualification reports are available upon request.

Our ASICs and power management ICs operate across -55°C to +175°C ambient temperatures, with derating curves provided in military temperature range (MTR) datasheets.

Our PMA parts (e.g., actuators, sensors) hold FAA/EASA Form 1 certification and match OEM form/fit/function. Installation requires SB/MB documentation per FAA AC 23.1529.

All NAS/MS fasteners include full DNA traceability: melt source (AMS 2301), heat/lot numbers, and AS9100-compliant MTRs with ultrasonic test reports.

AOG orders ship within 4 hours for stocked items (FAA-PMA, EASA Part 21G). Non-stock critical parts trigger priority manufacturing with 72-hour max turnaround.

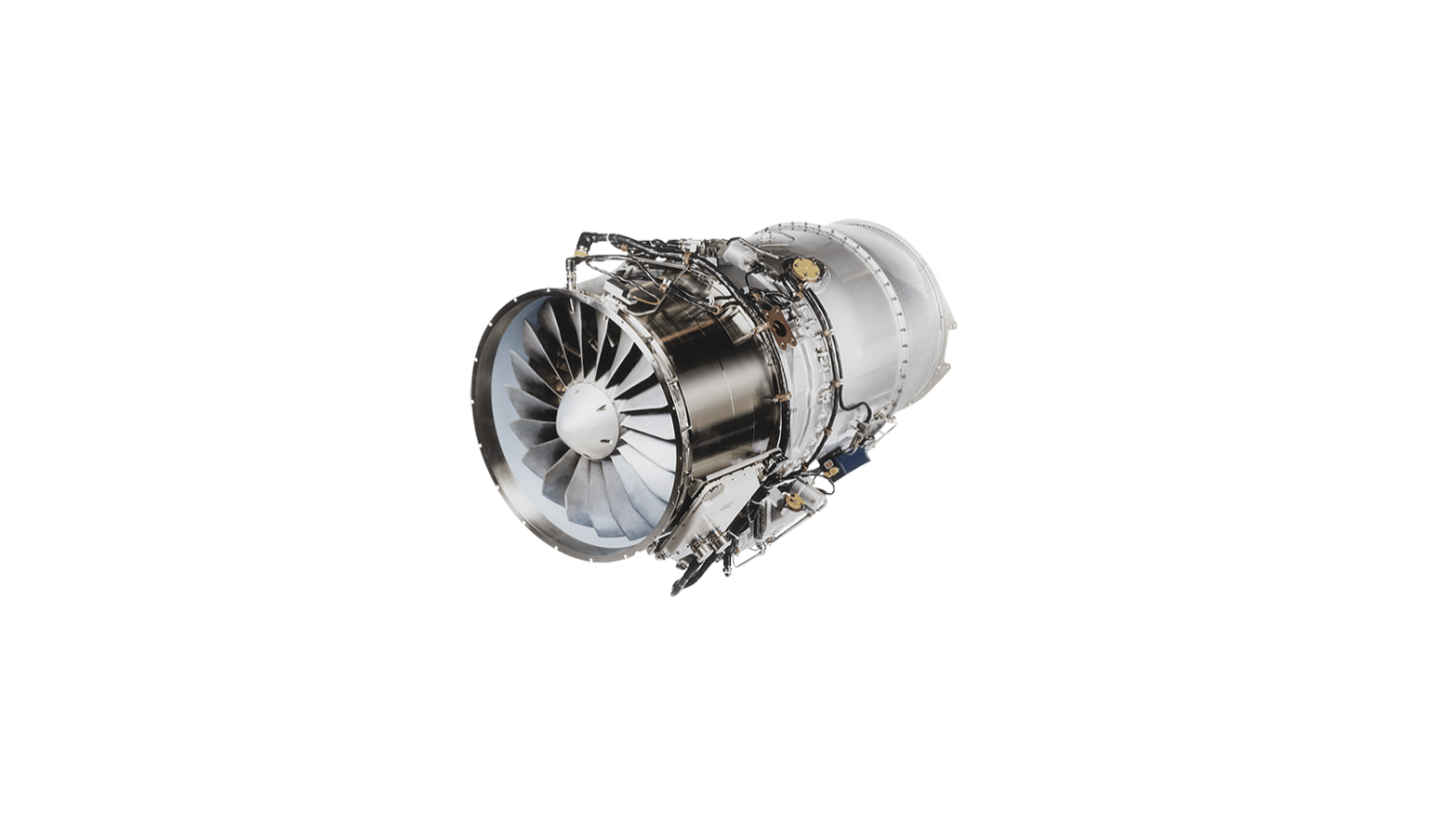

Gas Turbine

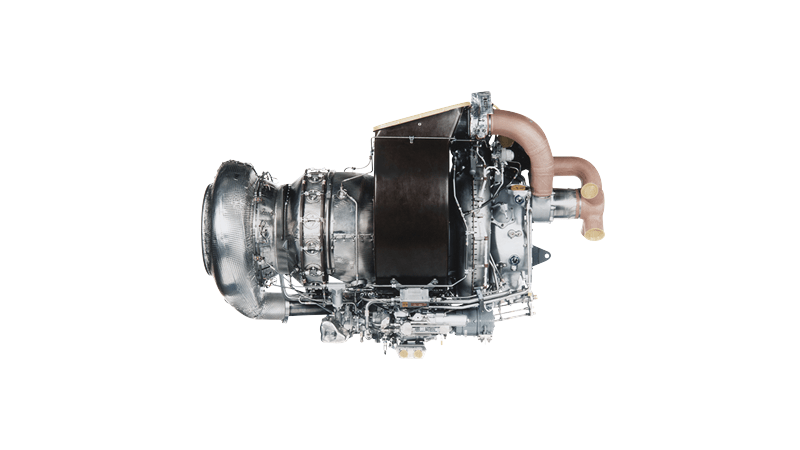

Gas Turbine

Aircraft parts

Aircraft parts