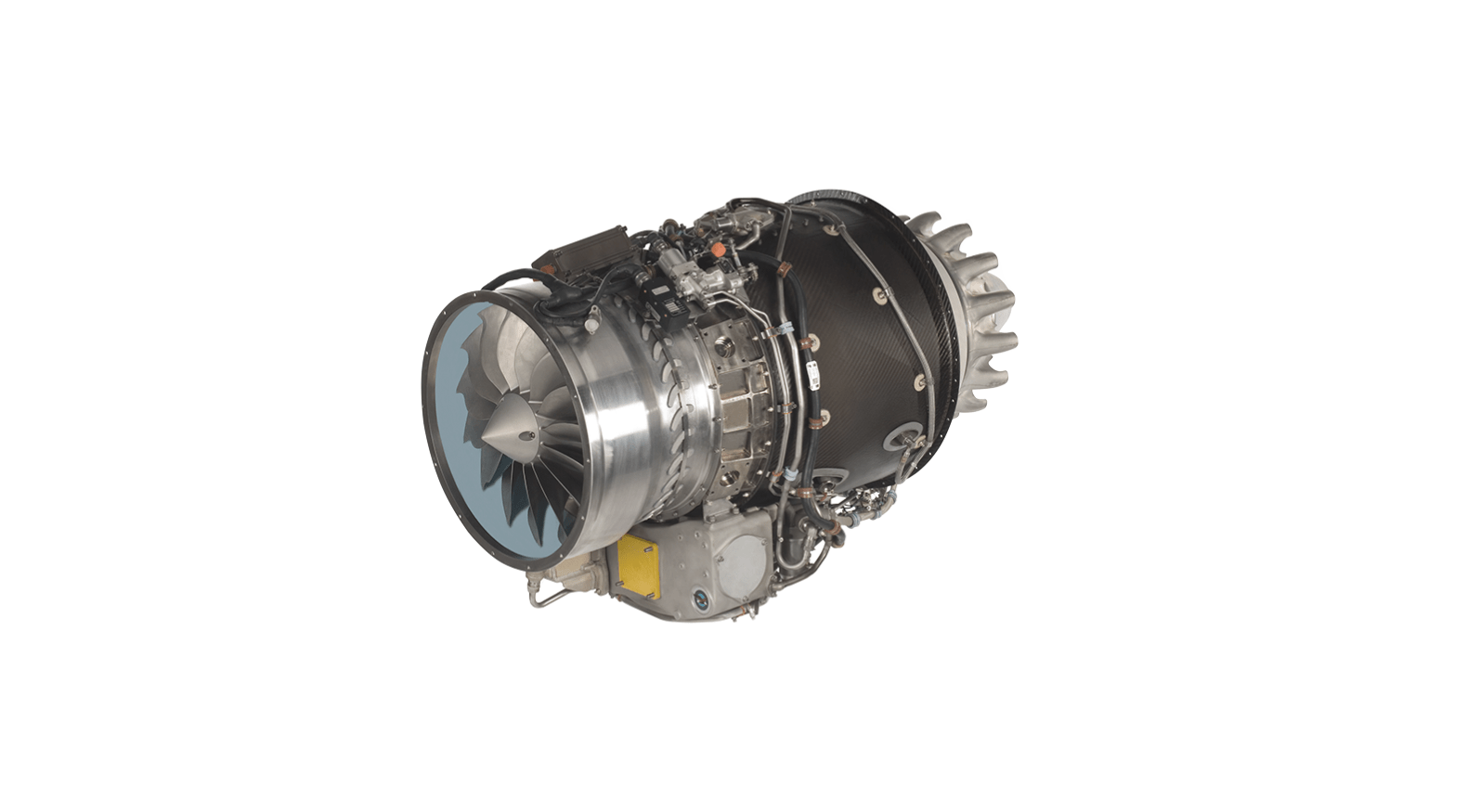

Pratt & Whitney has taken its successful PW4000 100-inch engine for the Airbus A330 to new heights with the introduction of the PW4170 Advantage70™ program.

The Advantage70 is offered as a new engine and as an upgrade kit for existing engines. Advantage70 technology delivers superior engine performance, including a 2 percent thrust increase, more than 1 percent reduction in fuel consumption, increased durability, and reduced maintenance costs.

Developed specifically for the Airbus A330 twinjet and introduced in 1994, the PW4000 100-inch fan engine has thrust capability from 64,500 to 70,000 pounds at take-off. The engine was the first in aviation history to qualify for Extended-range Twin-engine Operations (ETOPS) prior to entering service. It is now approved for 180-minute ETOPS.

Pratt & Whitney supplies A330 customers the entire propulsion system - engine, nacelle, thrust reverser and accessories. This, along with superb service reliability, excellent performance retention and low cost of ownership, make the PW4000 100-inch engine an outstanding value.

Fan Tip Diameter

100 In

Length, Flange To Flange

163.1 In

Takeoff Thrust

64,500–70,000 Lb

Flat Rated Temperature

86°F

Bypass Ratio

5.0

Overall Pressure Ratio (Takeoff)

32.0–35.4

Fan Pressure Ratio

1.75

Yes, we retrofit legacy systems (e.g., GE Frame 5, Siemens V94.2) with modern digital controllers, typically completing hardware integration within 4-8 weeks. Software migration requires additional validation time.

We recommend annual performance testing under ISO 3977-2 standards. Critical applications (e.g., offshore platforms) may require semi-annual tests with emissions compliance checks.

All rad-hard devices (e.g., FPGA, ADC) are QML Class V certified under MIL-PRF-38535 and tested to MIL-STD-883 Method 1019 for SEU tolerance. Full qualification reports are available upon request.

Our ASICs and power management ICs operate across -55°C to +175°C ambient temperatures, with derating curves provided in military temperature range (MTR) datasheets.

Our PMA parts (e.g., actuators, sensors) hold FAA/EASA Form 1 certification and match OEM form/fit/function. Installation requires SB/MB documentation per FAA AC 23.1529.

All NAS/MS fasteners include full DNA traceability: melt source (AMS 2301), heat/lot numbers, and AS9100-compliant MTRs with ultrasonic test reports.

AOG orders ship within 4 hours for stocked items (FAA-PMA, EASA Part 21G). Non-stock critical parts trigger priority manufacturing with 72-hour max turnaround.

Gas Turbine

Gas Turbine

Aircraft parts

Aircraft parts