The V2500TM engine is designed and manufactured by IAE International Aero Engines AG, a global partnership of aerospace leaders including Pratt & Whitney, Pratt & Whitney Aero Engines International GmbH, Japanese Aero Engines Corporation and MTU Aero Engines AG.

IAE International Aero Engines AG brings advantages in technical excellence and manufacturing expertise, with a reputation of producing the engine of choice for the Airbus A320ceo family.

With enhanced service options to meet our customers’ evolving needs, the V2500™ engine is designed to maximize time on wing while delivering best-in-class fuel consumption, noise and emissions. Setting the standard for reliability, the V2500 engine — with ongoing production and a committed supply base — will support our customers’ efficient operations for many years to come.

The V2500 engine remains the quietest, most fuel-efficient engine for the Airbus A320ceo family, with the lowest emissions and greatest advantage in aircraft payload and range.

Cargo

The V2500 engine powered the first A320 and A321 passenger-to-cargo conversions, offers asignificant payload-rangeadvantage, and is the onlyengine on the A321ceo to meetChapter 4 noise standards out ofthe box.

The V2500-E5 engine provides 31,000 pounds of thrust with efficient, clean power for the C-390 Millennium multi-mission transport aircraft, developed by Embraer.

Fuel burn advantage

The V2500 engine remains the quietest, most fuel efficient engine for the Airbus A320ceo family, with up to 3% better fuel burn, the lowest emissions, and a significant payload-range advantage.

Unmatched versatility

The V2500 engine has versatile applications, powering commercial, cargo, and military platforms.

Reliable performance

With up to 33,000 pounds of thrust, the V2500 engine has surpassed 300 million flight hours and currently powers approximately 2,800 aircraft, serving more than 150 operators around the world.

Tailored service solutions

As engines evolve through their life cycles, we’re working with our customers to offer enhanced service solutions to meet their needs.

Yes, we retrofit legacy systems (e.g., GE Frame 5, Siemens V94.2) with modern digital controllers, typically completing hardware integration within 4-8 weeks. Software migration requires additional validation time.

We recommend annual performance testing under ISO 3977-2 standards. Critical applications (e.g., offshore platforms) may require semi-annual tests with emissions compliance checks.

All rad-hard devices (e.g., FPGA, ADC) are QML Class V certified under MIL-PRF-38535 and tested to MIL-STD-883 Method 1019 for SEU tolerance. Full qualification reports are available upon request.

Our ASICs and power management ICs operate across -55°C to +175°C ambient temperatures, with derating curves provided in military temperature range (MTR) datasheets.

Our PMA parts (e.g., actuators, sensors) hold FAA/EASA Form 1 certification and match OEM form/fit/function. Installation requires SB/MB documentation per FAA AC 23.1529.

All NAS/MS fasteners include full DNA traceability: melt source (AMS 2301), heat/lot numbers, and AS9100-compliant MTRs with ultrasonic test reports.

AOG orders ship within 4 hours for stocked items (FAA-PMA, EASA Part 21G). Non-stock critical parts trigger priority manufacturing with 72-hour max turnaround.

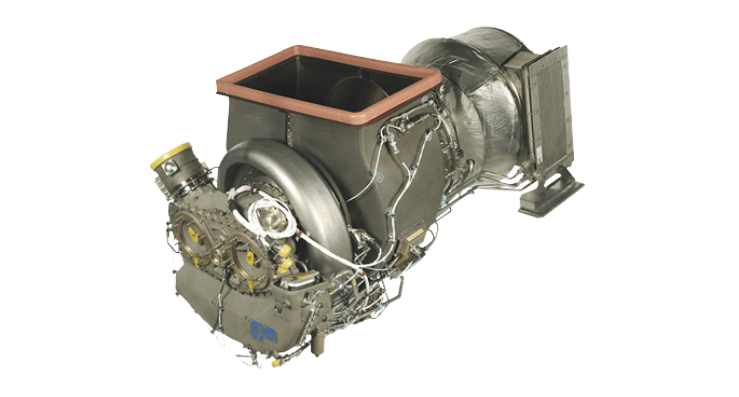

Gas Turbine

Gas Turbine

Aircraft parts

Aircraft parts