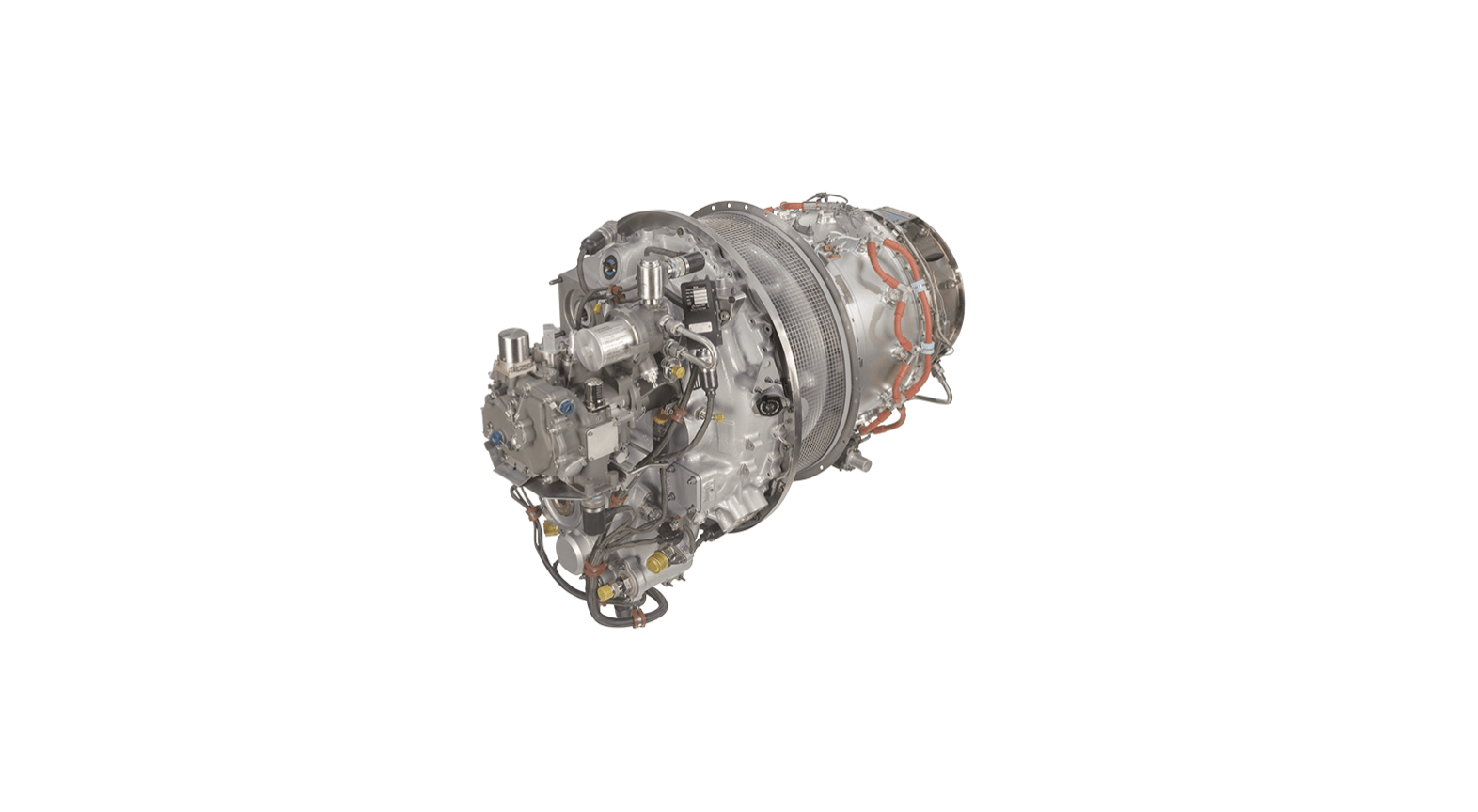

The Pratt & Whitney APS2300 APU was designed for the rigorous utilization of 60- to 110-passenger regional jet aircraft, namely the Embraer 170/195-series aircraft. The APS2300 is generally accepted as the industry’s most reliable APU available today. The APS2300 APU is installed in Embraer's fleet of E170/175/190/195 regional jets as well as Embraer's Lineage 1000 business jets. The APS2300 APU is an integral bleed, constant speed, continuous cycle gas turbine engine that incorporates a single-stage centrifugal compressor, a reverse flow annular combustor, and a two-stage axial turbine. The APS2600 APU is the latest generation regional aircraft APU system available today. Derived from the APS2300, it has been designed to match today's regional market requirements.

Yes, we retrofit legacy systems (e.g., GE Frame 5, Siemens V94.2) with modern digital controllers, typically completing hardware integration within 4-8 weeks. Software migration requires additional validation time.

We recommend annual performance testing under ISO 3977-2 standards. Critical applications (e.g., offshore platforms) may require semi-annual tests with emissions compliance checks.

All rad-hard devices (e.g., FPGA, ADC) are QML Class V certified under MIL-PRF-38535 and tested to MIL-STD-883 Method 1019 for SEU tolerance. Full qualification reports are available upon request.

Our ASICs and power management ICs operate across -55°C to +175°C ambient temperatures, with derating curves provided in military temperature range (MTR) datasheets.

Our PMA parts (e.g., actuators, sensors) hold FAA/EASA Form 1 certification and match OEM form/fit/function. Installation requires SB/MB documentation per FAA AC 23.1529.

All NAS/MS fasteners include full DNA traceability: melt source (AMS 2301), heat/lot numbers, and AS9100-compliant MTRs with ultrasonic test reports.

AOG orders ship within 4 hours for stocked items (FAA-PMA, EASA Part 21G). Non-stock critical parts trigger priority manufacturing with 72-hour max turnaround.

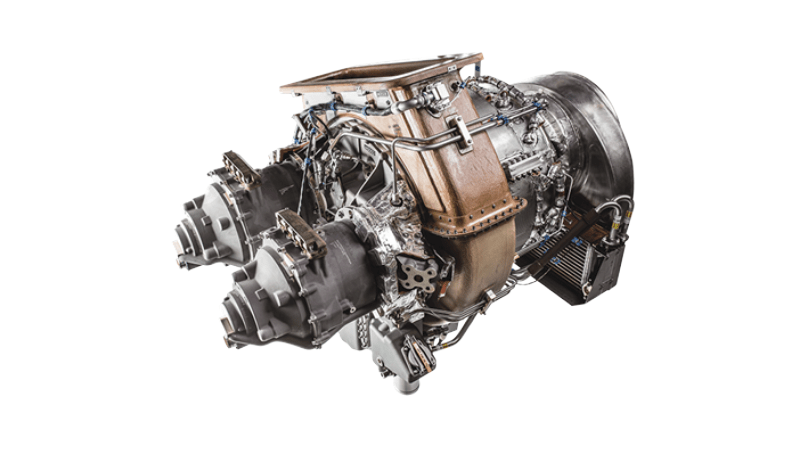

Gas Turbine

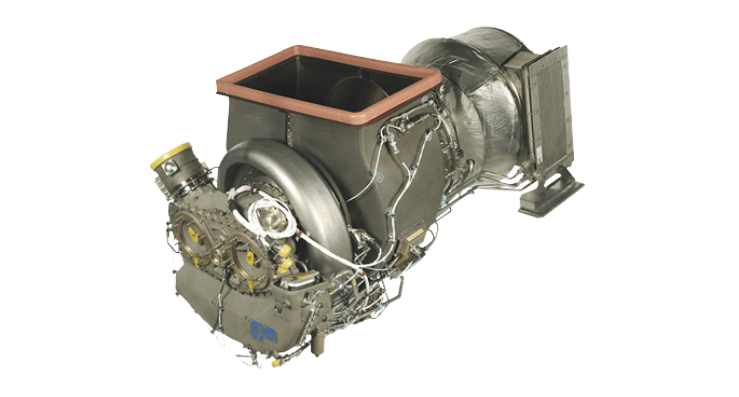

Gas Turbine

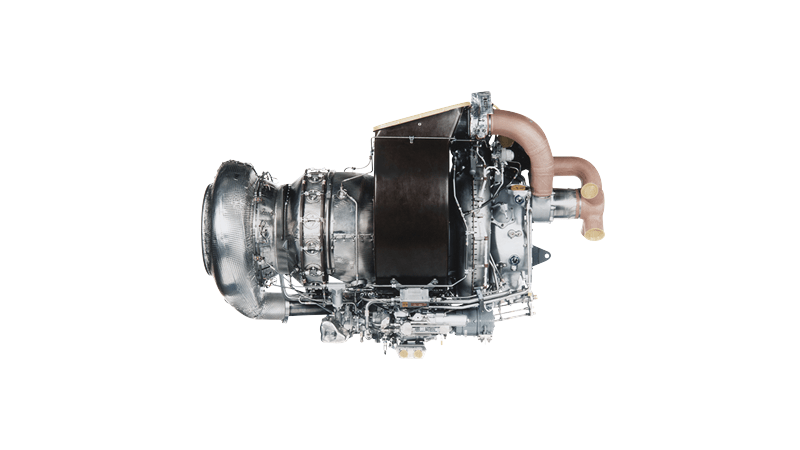

Aircraft parts

Aircraft parts