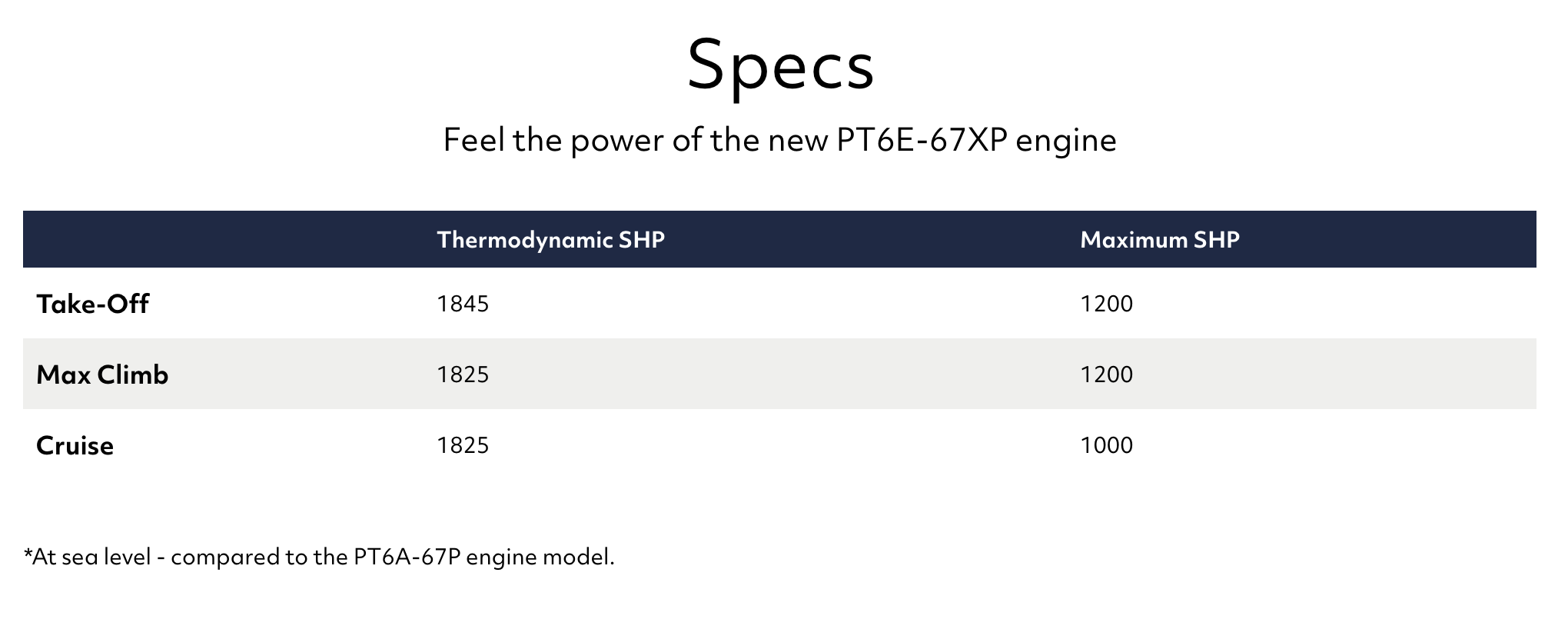

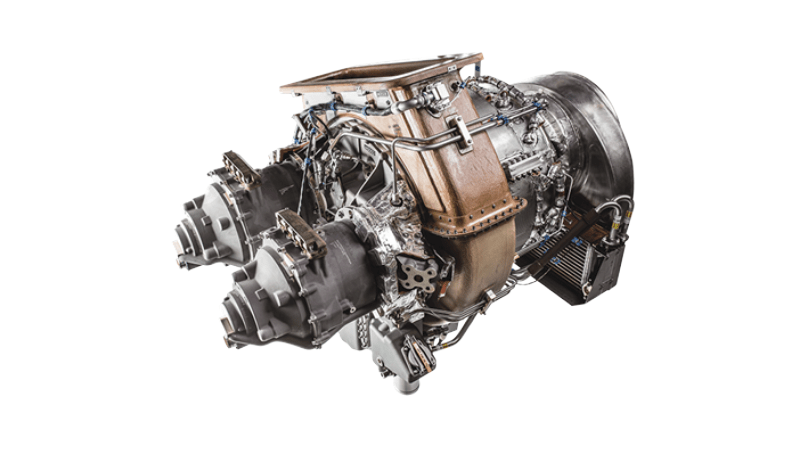

The PT6E-67XP engine for the Pilatus PC-12 NGX, raises the bar in engine performance, control systems, data intelligence and service solutions.

The PT6 E-Series™ engine – the first engine family with a dual-channel integrated electronic propeller and engine control system in the General Aviation turboprop market.

The DNA you trust, pushing innovation to a new level.

Flying just got easier – Experience a more intuitive way of flying, from engine start to propeller and engine control. The PT6E-67XP engine simplifies your operation, so you can focus on what’s going on around you and enjoy your flying experience even more.

Precise and predictable – Fly with even more peace of mind, knowing the PT6E-67XP engine has not one but two independent control systems. As the electronic engine control (EEC) receives all engine and key aircraft data, it is able to make the necessary adjustments to optimize and deliver the right engine power needed throughout the flight.

Every flight is personal – It’s that feeling that comes from knowing you’ve got all the information you need to make informed decisions. Upon landing, all engine flight data is wirelessly downloaded, providing valuable new insights into the performance and health of the engine.

Our Eagle Service™ Plan (ESP™) Platinum maintenance program for the PT6E-67XP-powered Pilatus PC-12 NGX takes it one step further. Engine data will be sent for trend monitoring and, if required, for troubleshooting. Armed with this information, Pratt & Whitney’s predictive analytics team, dedicated engineers and data analysts using leading-edge technology and systems will provide personalized, proactive recommendations. Equipped with these new insights, you and your maintainer will have access to the latest technical information to maximize your engine’s time on-wing and reduce operating costs.

Simplified maintenance and increased availability

Since the PT6 E-Series™ engine is digitally connected, more than 100 parameters are continuously monitored to allow for predictive analysis and proactive maintenance planning, so you will always be a step ahead. The insights gained through the new data means you can maximize your operations and fly when you need to and for longer periods.

Eagle Service™ Plan (ESP™)

ESP™ Platinum for your PT6E-67XP engine gives you the most extensive coverage, backed by one of the world’s largest service networks

Yes, we retrofit legacy systems (e.g., GE Frame 5, Siemens V94.2) with modern digital controllers, typically completing hardware integration within 4-8 weeks. Software migration requires additional validation time.

We recommend annual performance testing under ISO 3977-2 standards. Critical applications (e.g., offshore platforms) may require semi-annual tests with emissions compliance checks.

All rad-hard devices (e.g., FPGA, ADC) are QML Class V certified under MIL-PRF-38535 and tested to MIL-STD-883 Method 1019 for SEU tolerance. Full qualification reports are available upon request.

Our ASICs and power management ICs operate across -55°C to +175°C ambient temperatures, with derating curves provided in military temperature range (MTR) datasheets.

Our PMA parts (e.g., actuators, sensors) hold FAA/EASA Form 1 certification and match OEM form/fit/function. Installation requires SB/MB documentation per FAA AC 23.1529.

All NAS/MS fasteners include full DNA traceability: melt source (AMS 2301), heat/lot numbers, and AS9100-compliant MTRs with ultrasonic test reports.

AOG orders ship within 4 hours for stocked items (FAA-PMA, EASA Part 21G). Non-stock critical parts trigger priority manufacturing with 72-hour max turnaround.

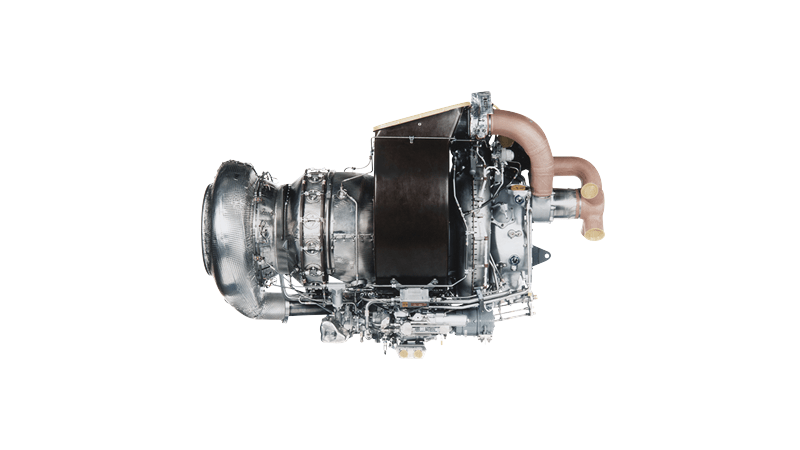

Gas Turbine

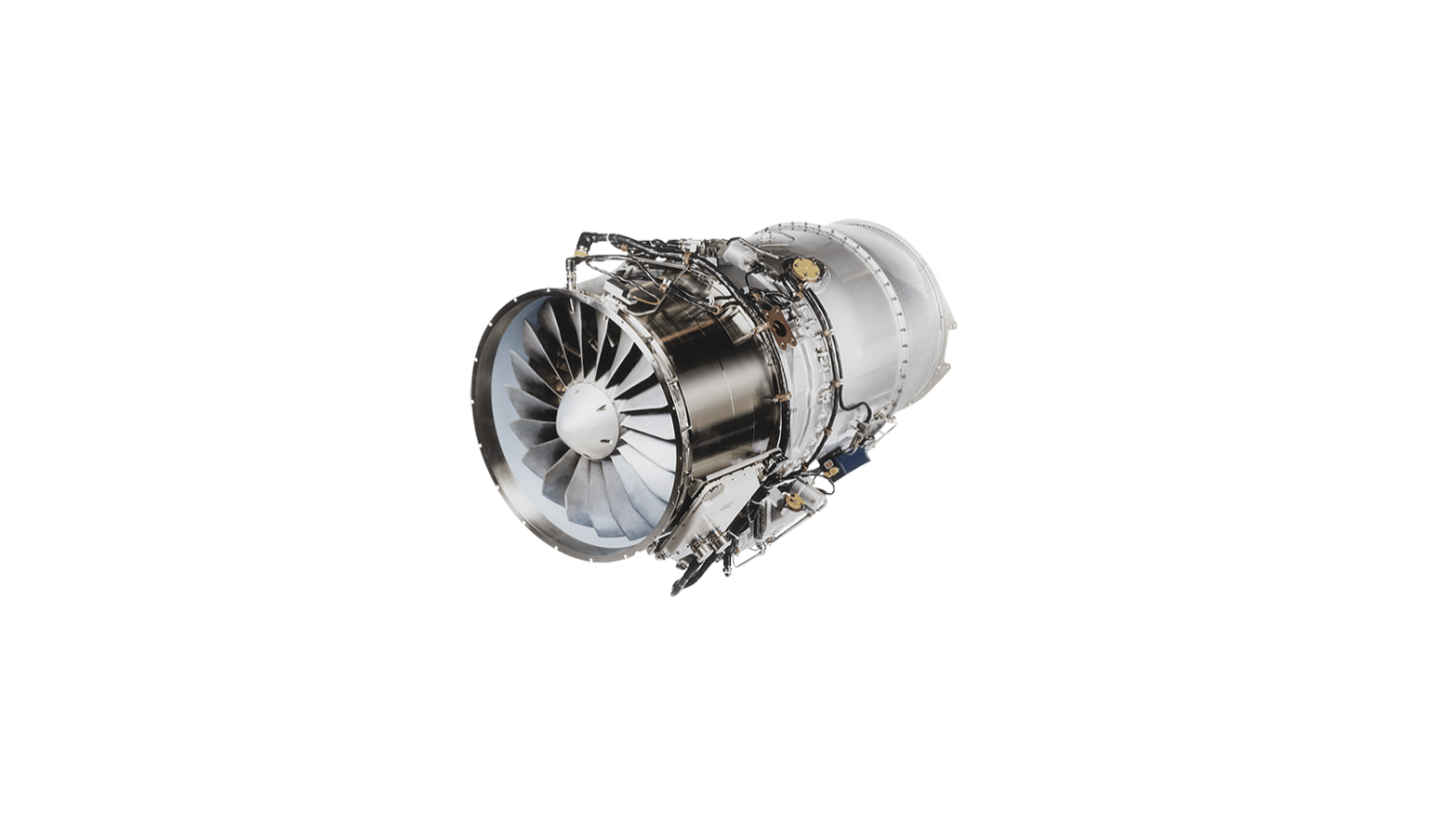

Gas Turbine

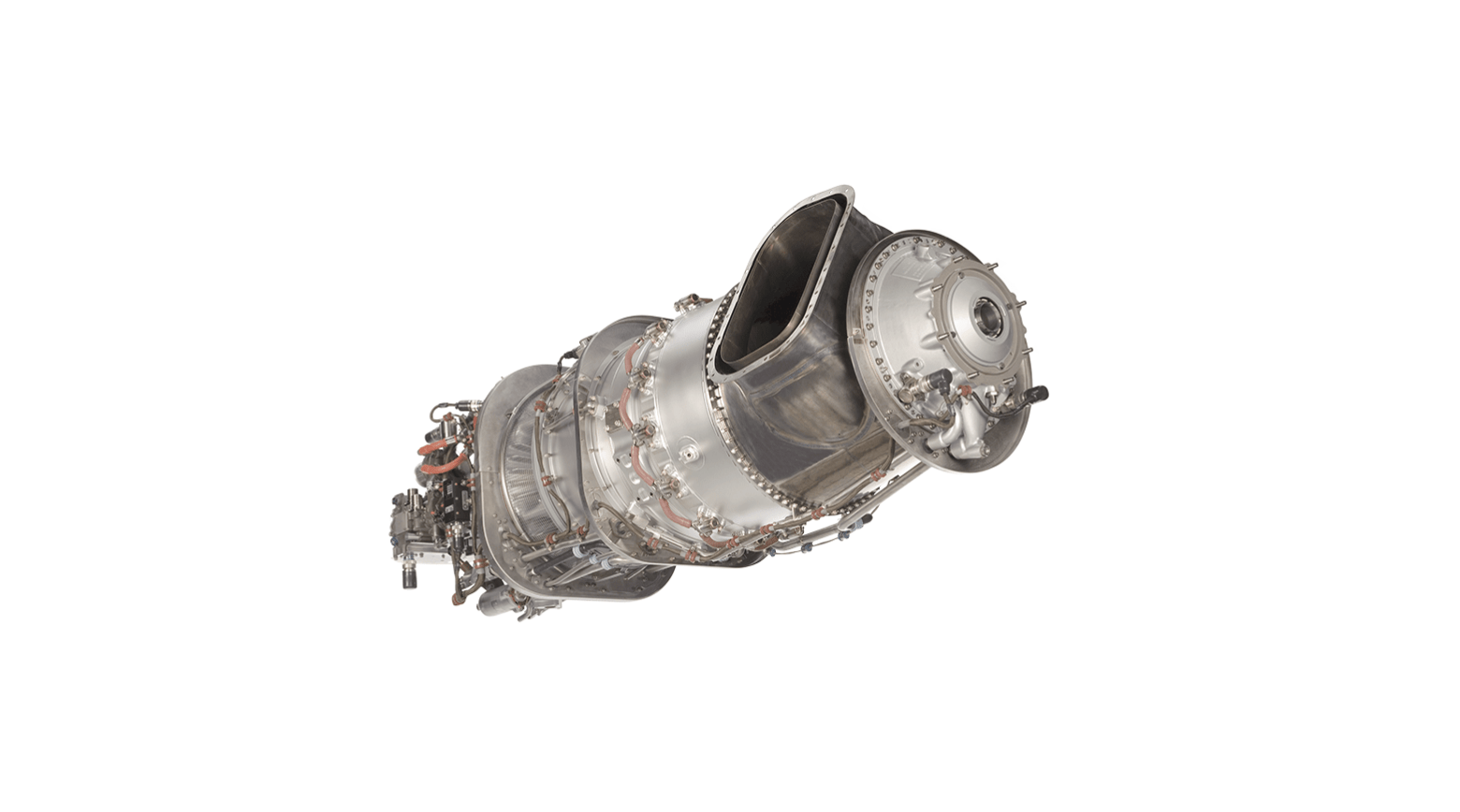

Aircraft parts

Aircraft parts