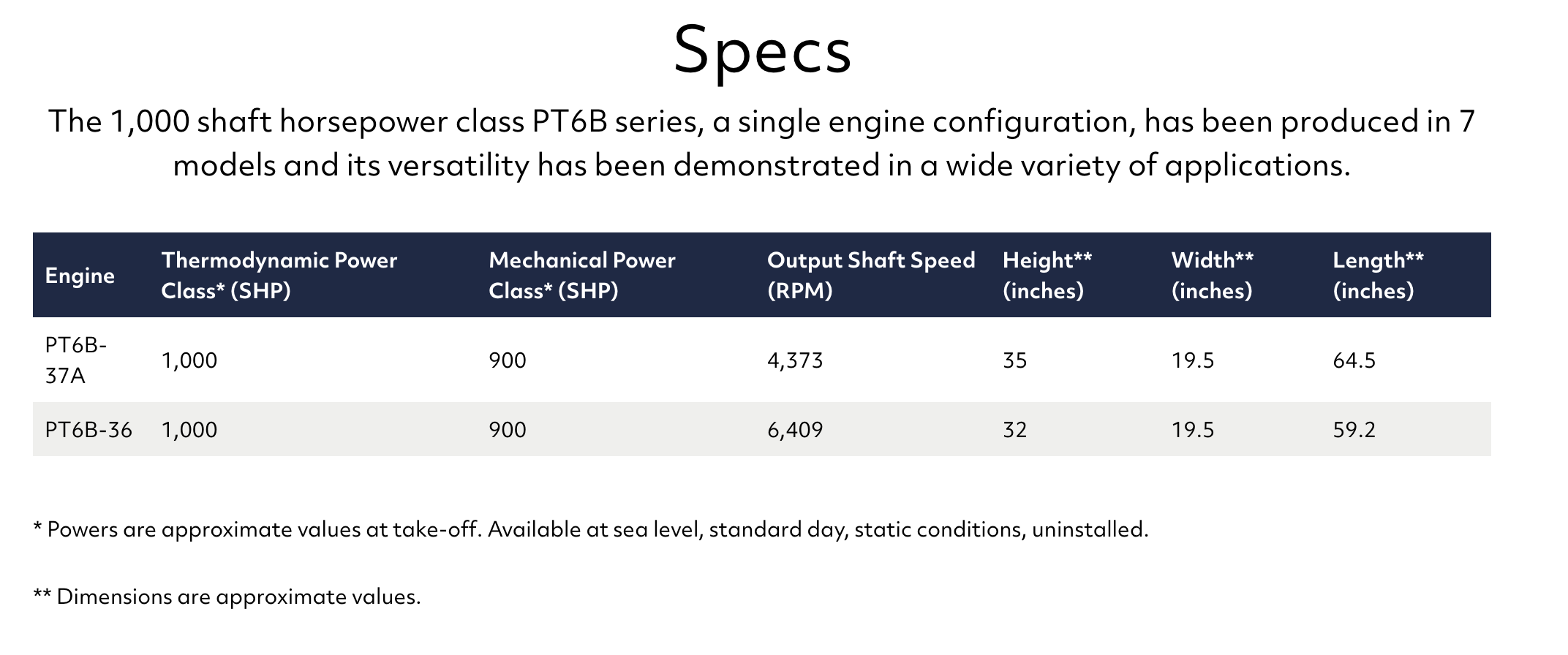

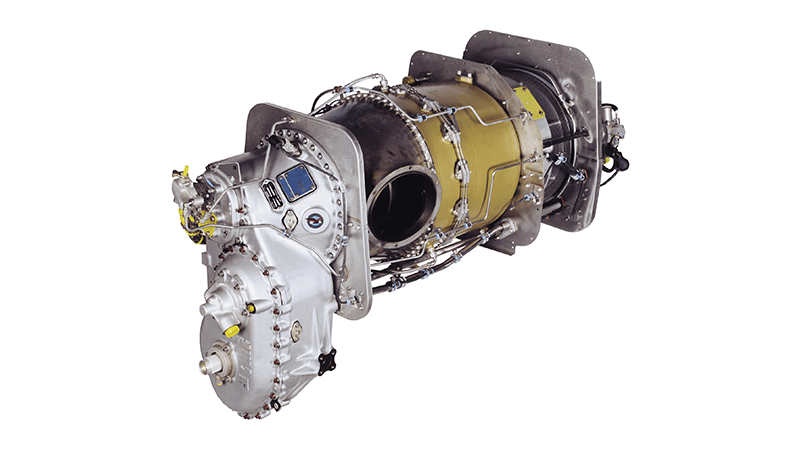

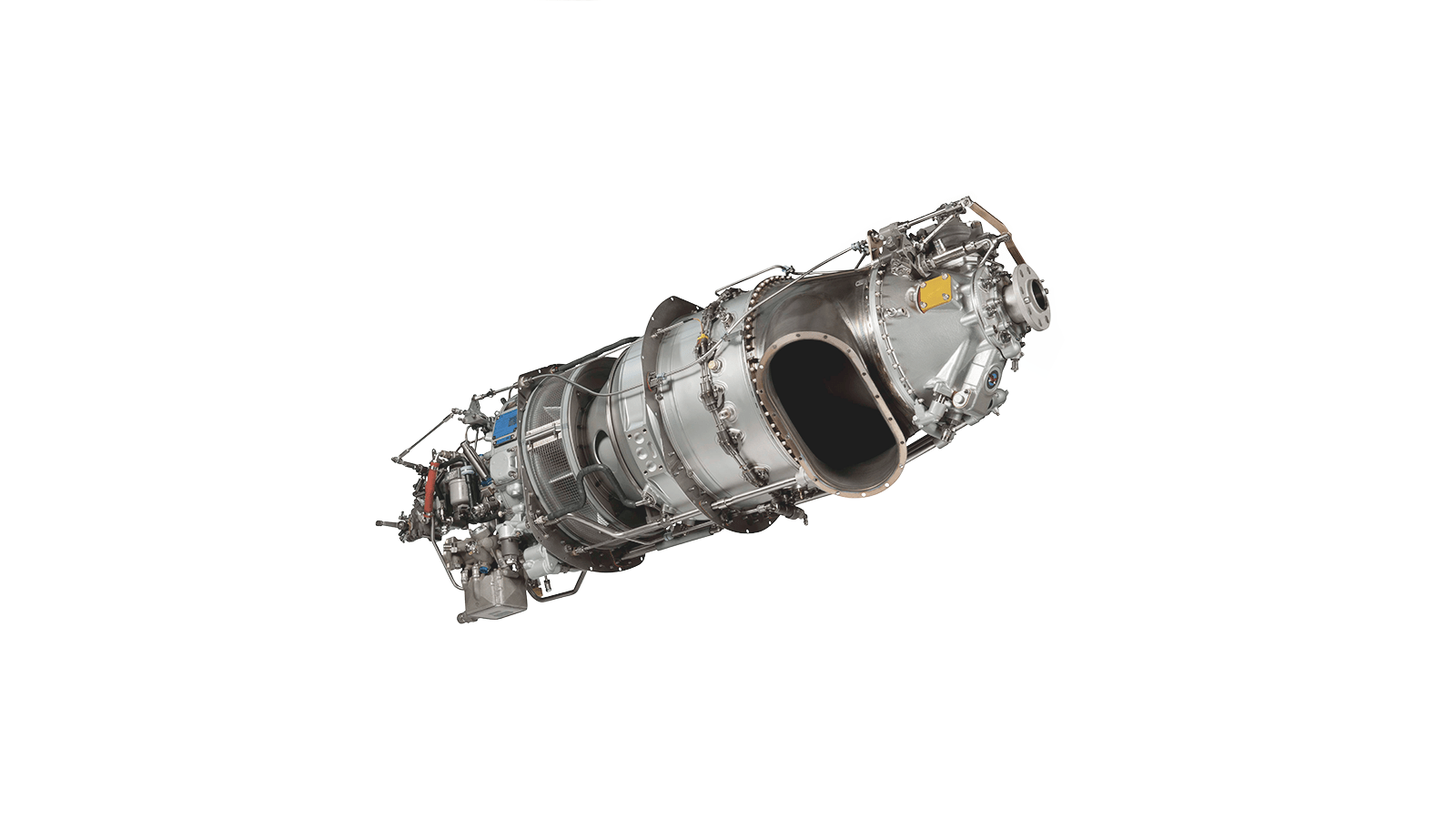

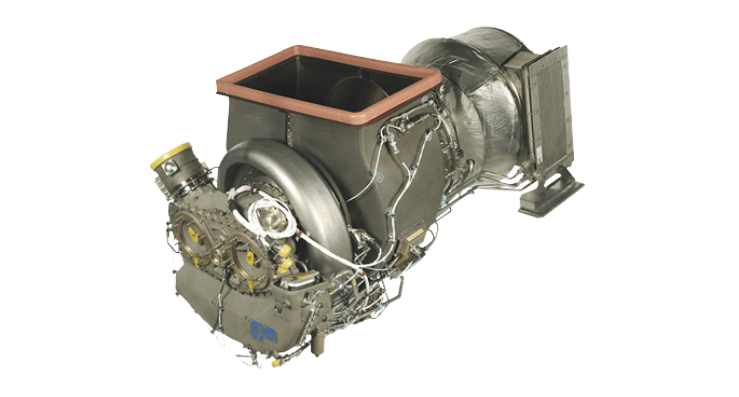

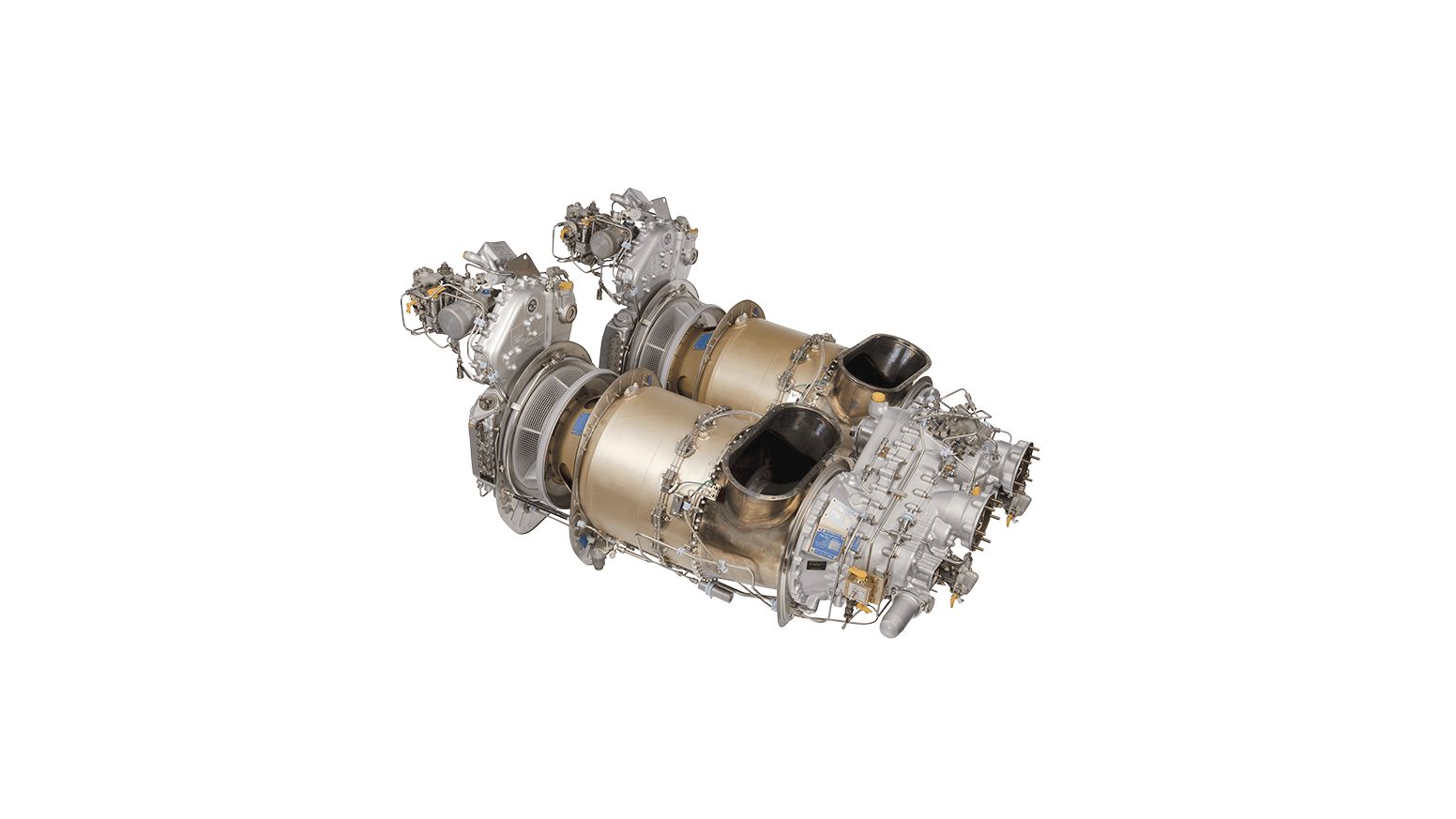

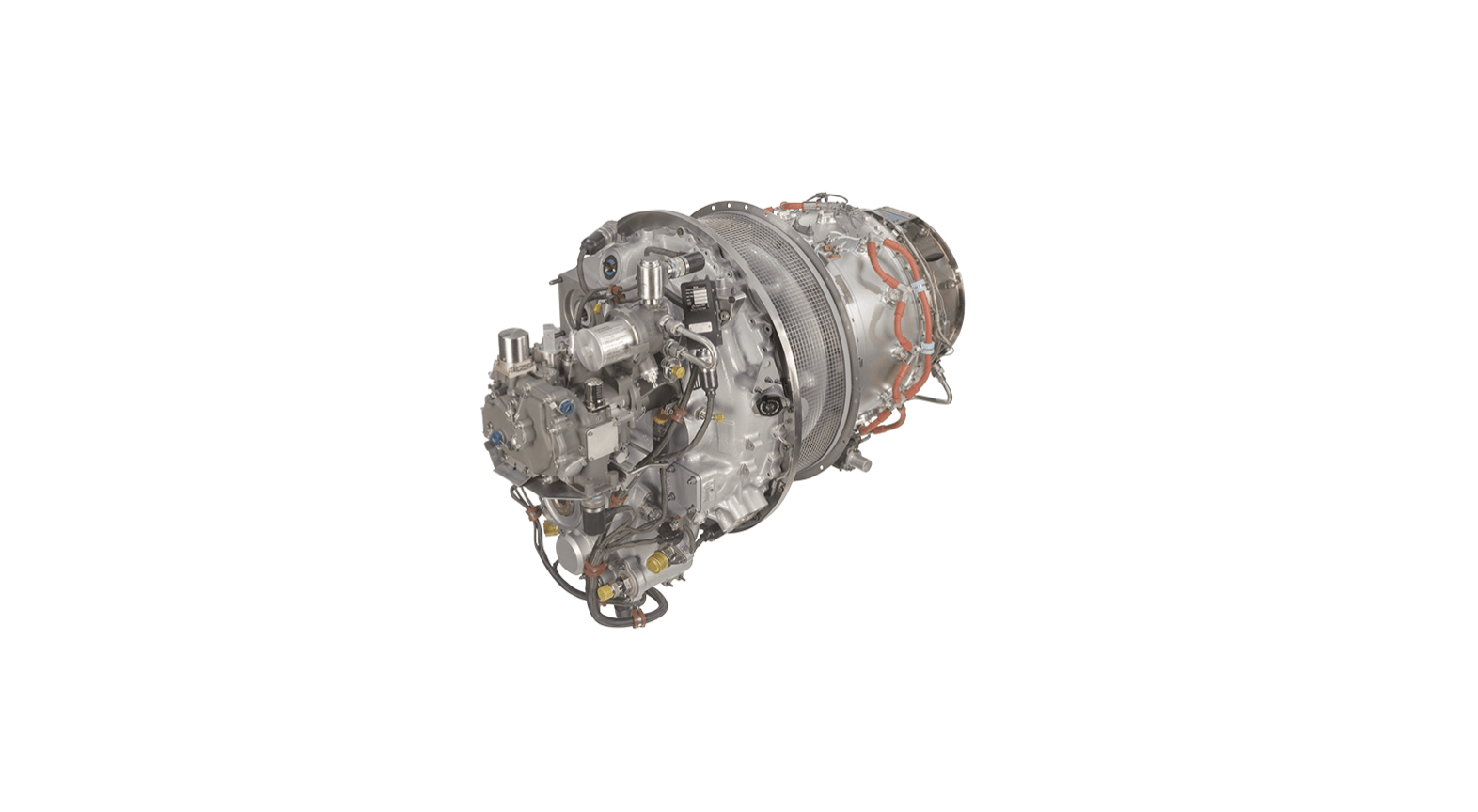

Powerful and versatile for single and twin-engine helicopters, the 1,000 shaft horsepower class PT6B is a direct derivative of the famous PT6T and PT6A family of engines.

The initial models in the PT6B Series was derived directly from the legendary PT6T Twin-Pac®, benefiting from its renowned dependability and performance.

The 1,000 shaft horsepower class PT6B series, a single engine configuration, has been produced in 7 models and its versatility has been demonstrated on a wide variety of applications. More recently, the PT6B-67A engine was developed with the PT6C-67A and PT6C-67C engine models providing the basis.

PT6B engines have been delivered to power helicopters around the world for emergency medical services, business and utility operations.

Plan your budget and minimize unscheduled maintenance with our Maintenance Programs: Eagle Service™ Plan (ESP™) for single aircraft, Fleet Service Plan (FSP) for growing fleets of two to five helicopters, and Fleet Management Plan (FMP) for fleets of six or more aircraft.

You can keep your helicopter in the air with our SMART program. Our two-year, 500-hour Certified PreOwned program benefits buyers and sellers of used helicopters.

Use our oil analysis technology, now included as part of Eagle Service™ Plan (ESP™) coverage. You may also purchase it separately through the MyP&WC Power portal.

Incorporating the Latest Technologies to Exceed Our Customers' Expectations

Key innovative design features have been introduced to the PT6B Series over the years to further increase its appeal in the market. The PT6B-37A has an automatic fuel control and an electronic power turbine governor with a manual back-up – a unique feature for single engine operations. The PT6B Series is derived directly from the PT6T-3D power section with an offset output gearbox, including clutch system. The basic engine configuration is exactly the same as that of the PT6T and PT6A turboprop, i.e. a two-shaft configuration consisting of a multi-stage compressor driven by a single-stage compressor turbine and an independent shaft coupling the power turbine to the output shaft through the offset reduction gearbox. In fact, the base engine hot section is very similar to the PT6A-34 airline turboprop, thus continuing the heritage of airline-level dependability in Pratt & Whitney's helicopter engines.

Yes, we retrofit legacy systems (e.g., GE Frame 5, Siemens V94.2) with modern digital controllers, typically completing hardware integration within 4-8 weeks. Software migration requires additional validation time.

We recommend annual performance testing under ISO 3977-2 standards. Critical applications (e.g., offshore platforms) may require semi-annual tests with emissions compliance checks.

All rad-hard devices (e.g., FPGA, ADC) are QML Class V certified under MIL-PRF-38535 and tested to MIL-STD-883 Method 1019 for SEU tolerance. Full qualification reports are available upon request.

Our ASICs and power management ICs operate across -55°C to +175°C ambient temperatures, with derating curves provided in military temperature range (MTR) datasheets.

Our PMA parts (e.g., actuators, sensors) hold FAA/EASA Form 1 certification and match OEM form/fit/function. Installation requires SB/MB documentation per FAA AC 23.1529.

All NAS/MS fasteners include full DNA traceability: melt source (AMS 2301), heat/lot numbers, and AS9100-compliant MTRs with ultrasonic test reports.

AOG orders ship within 4 hours for stocked items (FAA-PMA, EASA Part 21G). Non-stock critical parts trigger priority manufacturing with 72-hour max turnaround.

Gas Turbine

Gas Turbine

Aircraft parts

Aircraft parts