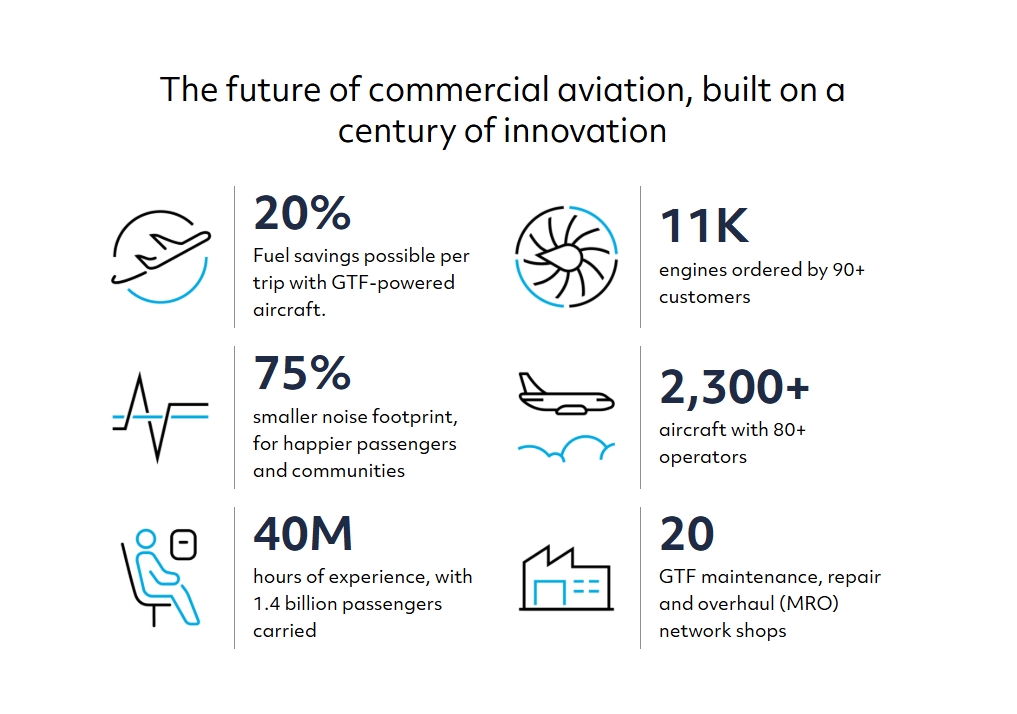

The Pratt & Whitney GTF™ engine is the only geared propulsion system delivering industry-leading fuel efficiency benefits.

Our geared fan has fundamentally changed how advanced propulsion works. Having quickly become the foundation of our industry’s future, our gear system has re-set the bar on the good that all other advanced technologies can deliver – from advanced materials to hybrid-electric systems to synthetic aviation fuels.

The GTF engine family is the quietest and most fuel-efficient in its class of single-aisle aircraft.

With unmatched fuel efficiency, payload and range, GTF engines are helping airlines open new routes and fly more people, farther, on less fuel.

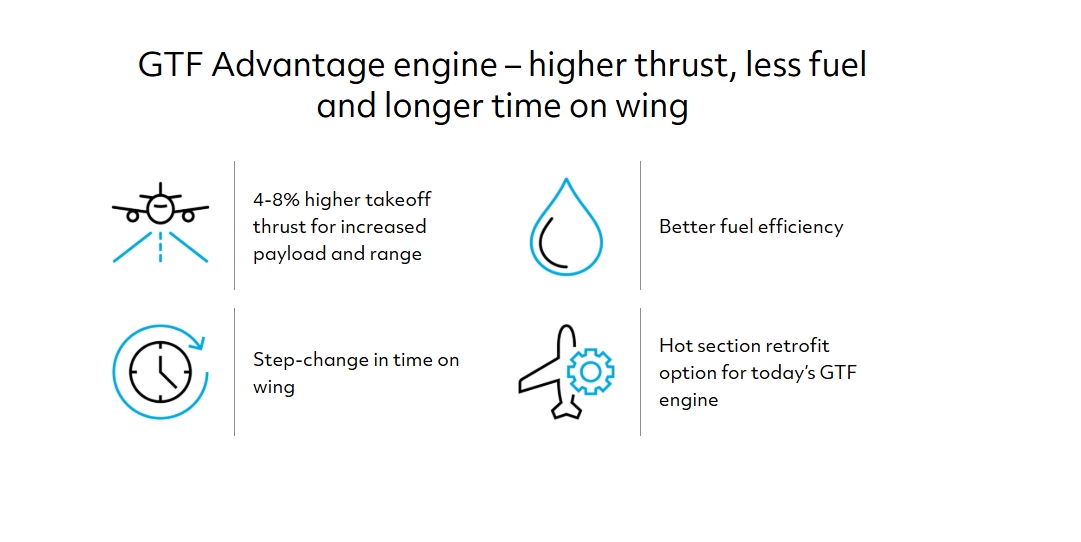

The game-changing geared fan technology will be the foundation for more efficient propulsion in the decades ahead. GTF engines are a generation ahead and, with GTF Advantage for A320neo family, proving their ability to unlock additional benefits.

Yes, we retrofit legacy systems (e.g., GE Frame 5, Siemens V94.2) with modern digital controllers, typically completing hardware integration within 4-8 weeks. Software migration requires additional validation time.

We recommend annual performance testing under ISO 3977-2 standards. Critical applications (e.g., offshore platforms) may require semi-annual tests with emissions compliance checks.

All rad-hard devices (e.g., FPGA, ADC) are QML Class V certified under MIL-PRF-38535 and tested to MIL-STD-883 Method 1019 for SEU tolerance. Full qualification reports are available upon request.

Our ASICs and power management ICs operate across -55°C to +175°C ambient temperatures, with derating curves provided in military temperature range (MTR) datasheets.

Our PMA parts (e.g., actuators, sensors) hold FAA/EASA Form 1 certification and match OEM form/fit/function. Installation requires SB/MB documentation per FAA AC 23.1529.

All NAS/MS fasteners include full DNA traceability: melt source (AMS 2301), heat/lot numbers, and AS9100-compliant MTRs with ultrasonic test reports.

AOG orders ship within 4 hours for stocked items (FAA-PMA, EASA Part 21G). Non-stock critical parts trigger priority manufacturing with 72-hour max turnaround.

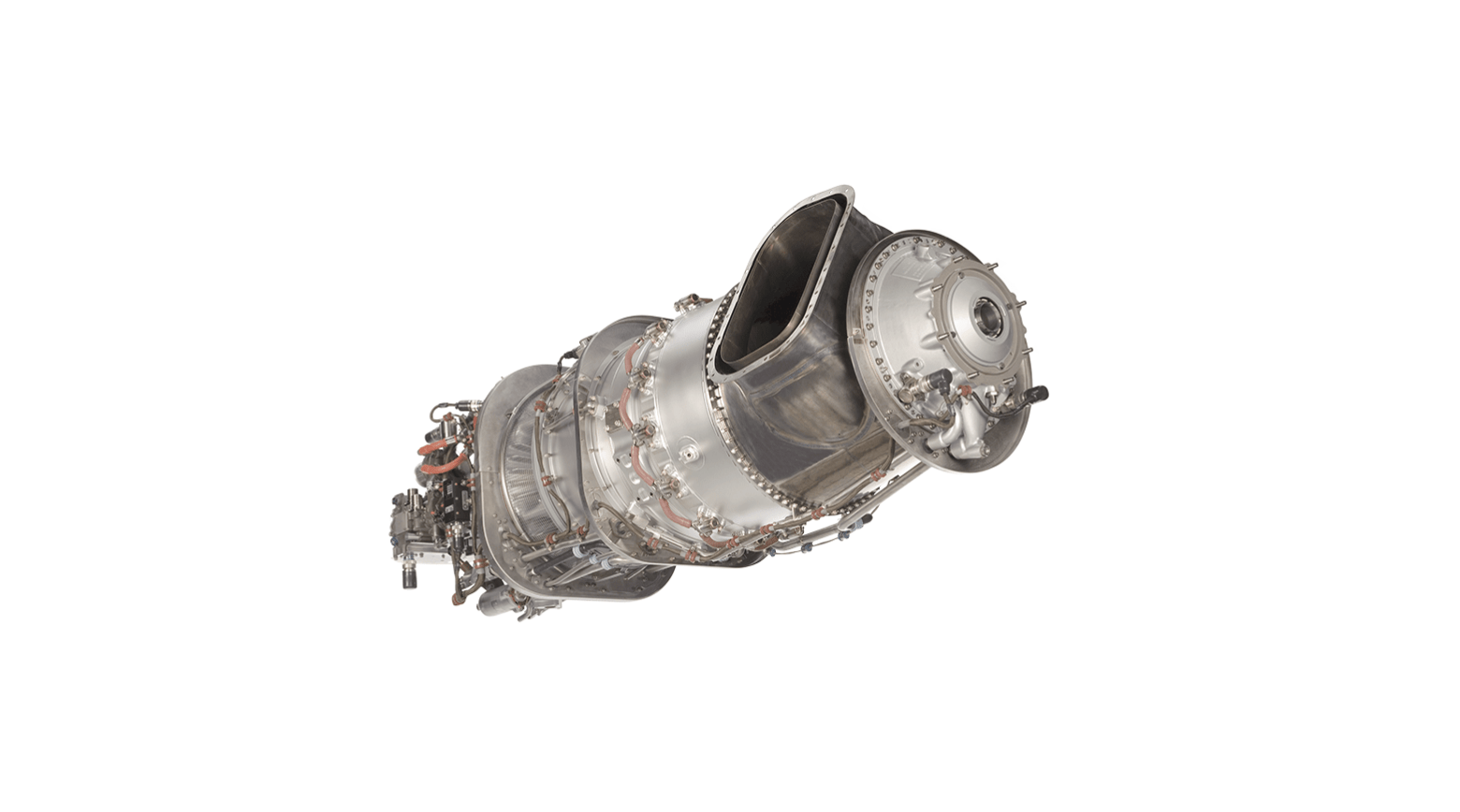

Gas Turbine

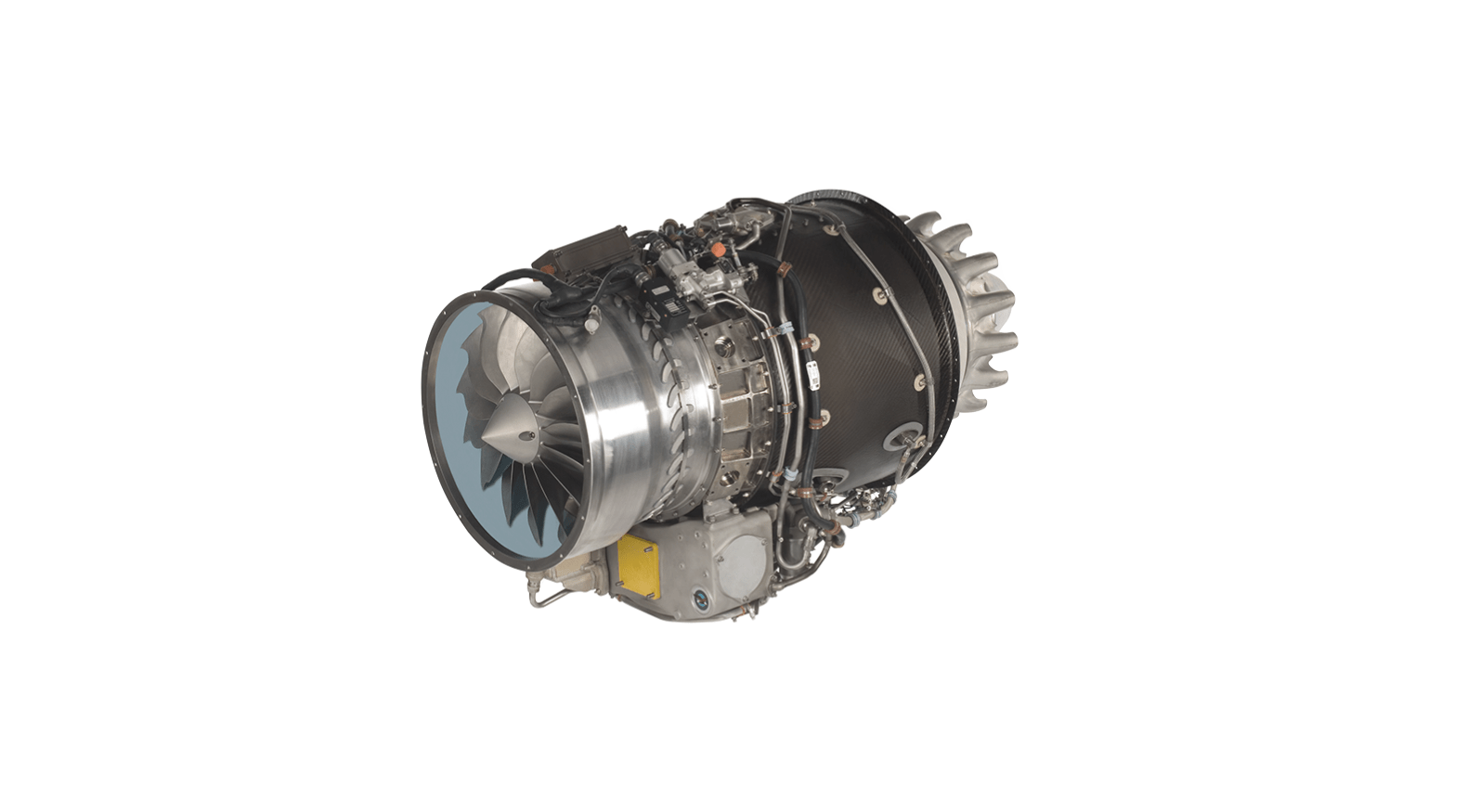

Gas Turbine

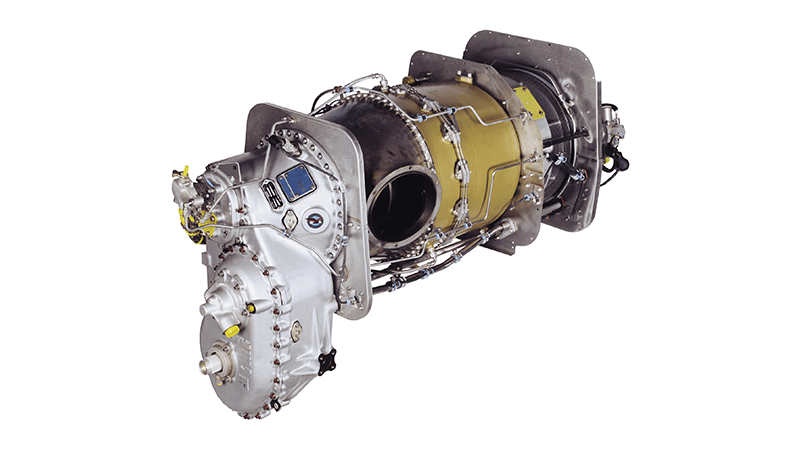

Aircraft parts

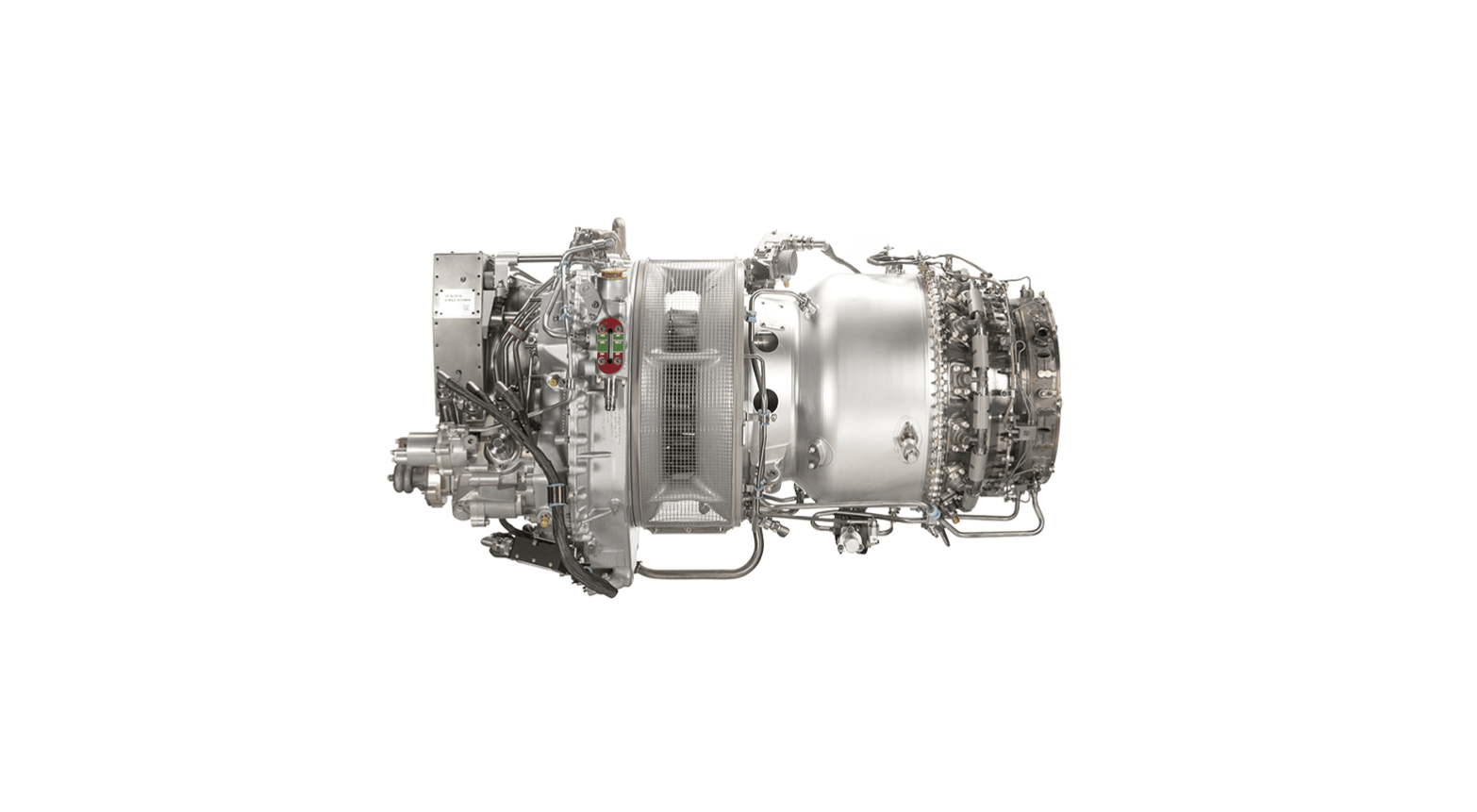

Aircraft parts