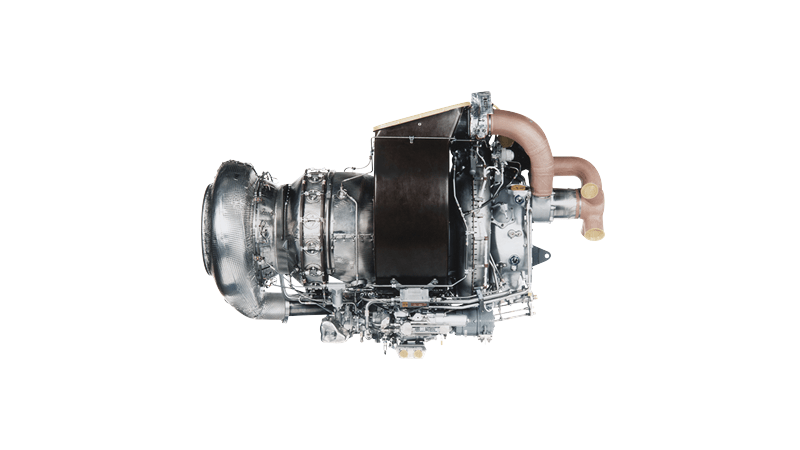

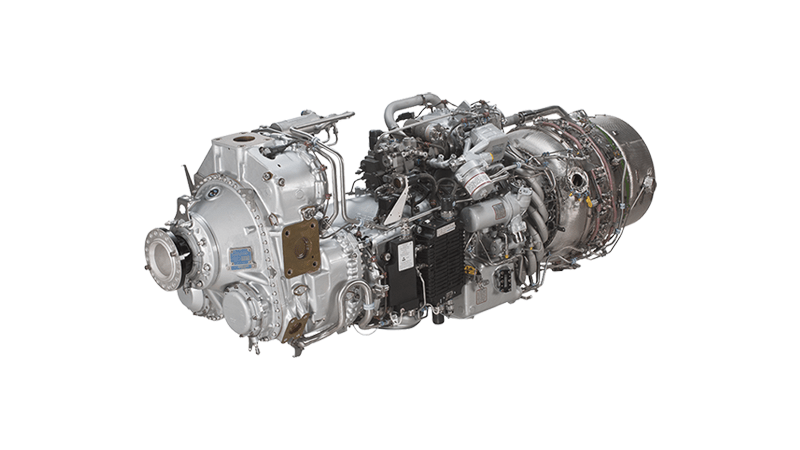

The PW800 engine family embodies the latest advances in technology. The PW800 is the most modern, efficient and environmentally responsible engine in its class. It offers double-digit improvements in fuel burn, emissions and noise as compared to the current generation of engines. It also offers 40% less scheduled maintenance and 20% fewer inspections than other engines in its class. It is supported by an exclusive, concierge-level service and advanced digital connectivity. For new generation, long- range business jets.

The PW800 provides an unsurpassed passenger experience, with the low-noise design and low vibration levels ensuring an exceptionally quiet cabin. With 40% less scheduled on-wing maintenance, it is the easiest engine in its class to access and maintain – and it’s backed by our proactive, seamless service and support network.

The PW800 over-delivers on reducing the engine’s footprint and moving toward a greener aviation world. Through our revolutionary technological innovations, we’re setting new sustainability standards and driving the whole industry onward.

The PW800 engine has been raising the bar on performance and economics for the long and ultra-long range business jet segments. It delivers the best overall performance, efficiency and quiet operation for high-speed aircraft, thanks to its optimized bypass ratio.

Yes, we retrofit legacy systems (e.g., GE Frame 5, Siemens V94.2) with modern digital controllers, typically completing hardware integration within 4-8 weeks. Software migration requires additional validation time.

We recommend annual performance testing under ISO 3977-2 standards. Critical applications (e.g., offshore platforms) may require semi-annual tests with emissions compliance checks.

All rad-hard devices (e.g., FPGA, ADC) are QML Class V certified under MIL-PRF-38535 and tested to MIL-STD-883 Method 1019 for SEU tolerance. Full qualification reports are available upon request.

Our ASICs and power management ICs operate across -55°C to +175°C ambient temperatures, with derating curves provided in military temperature range (MTR) datasheets.

Our PMA parts (e.g., actuators, sensors) hold FAA/EASA Form 1 certification and match OEM form/fit/function. Installation requires SB/MB documentation per FAA AC 23.1529.

All NAS/MS fasteners include full DNA traceability: melt source (AMS 2301), heat/lot numbers, and AS9100-compliant MTRs with ultrasonic test reports.

AOG orders ship within 4 hours for stocked items (FAA-PMA, EASA Part 21G). Non-stock critical parts trigger priority manufacturing with 72-hour max turnaround.

Gas Turbine

Gas Turbine

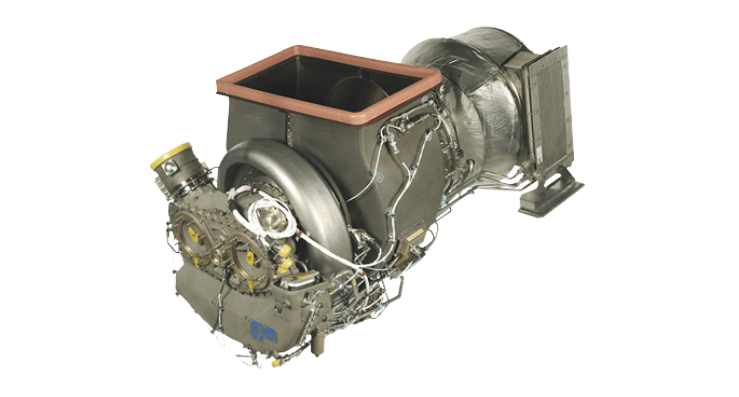

Aircraft parts

Aircraft parts