Born of power and efficiency

The largest and most powerful commercial aircraft engine ever built

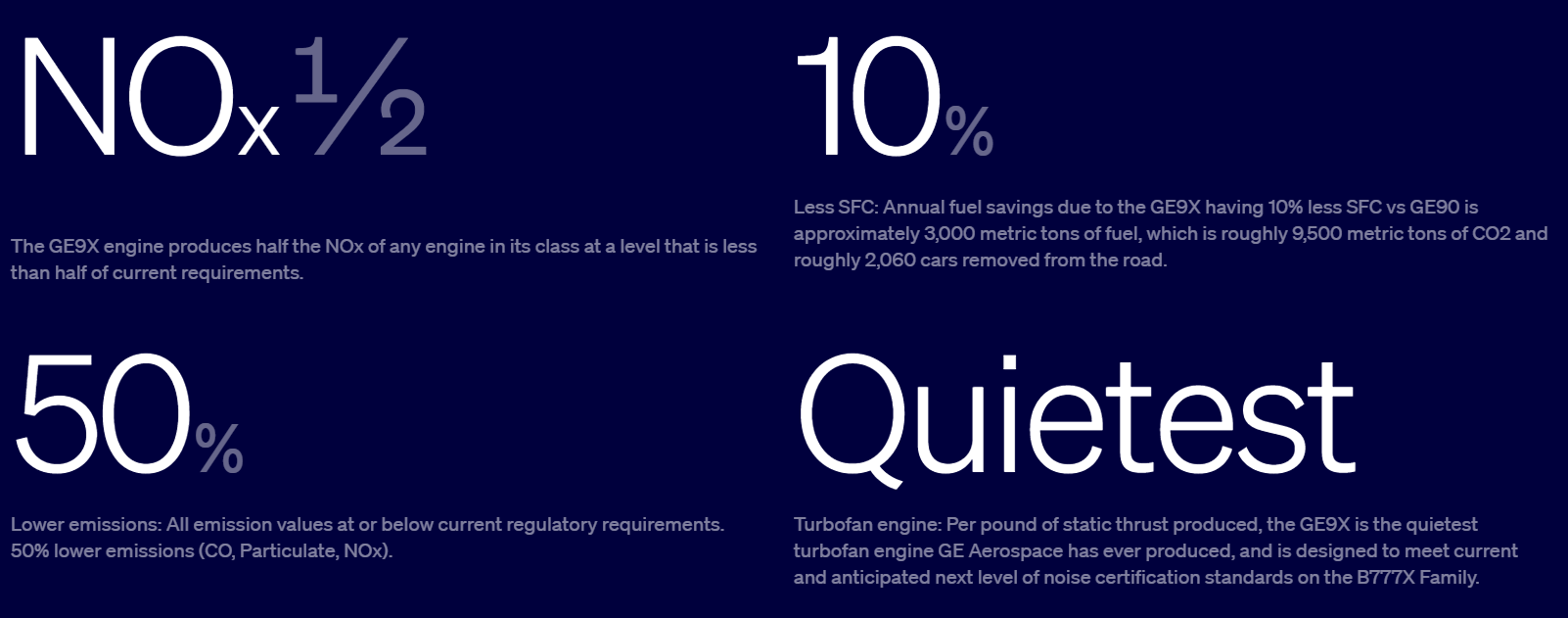

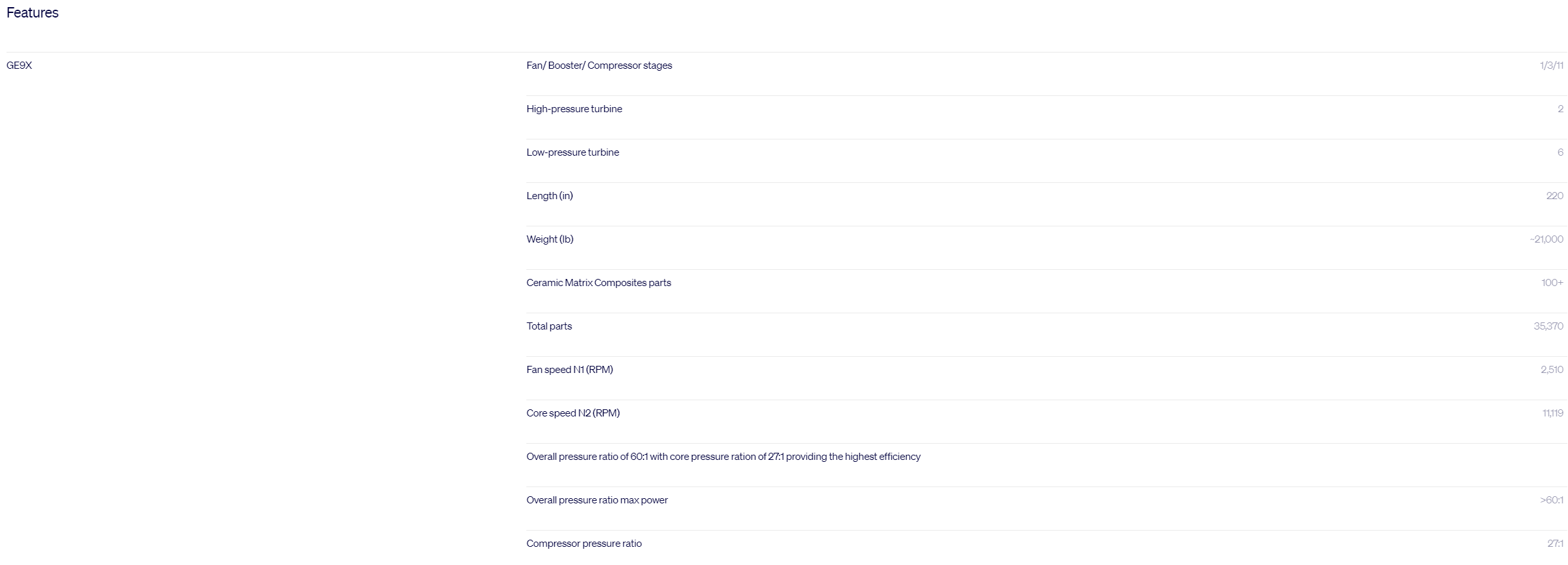

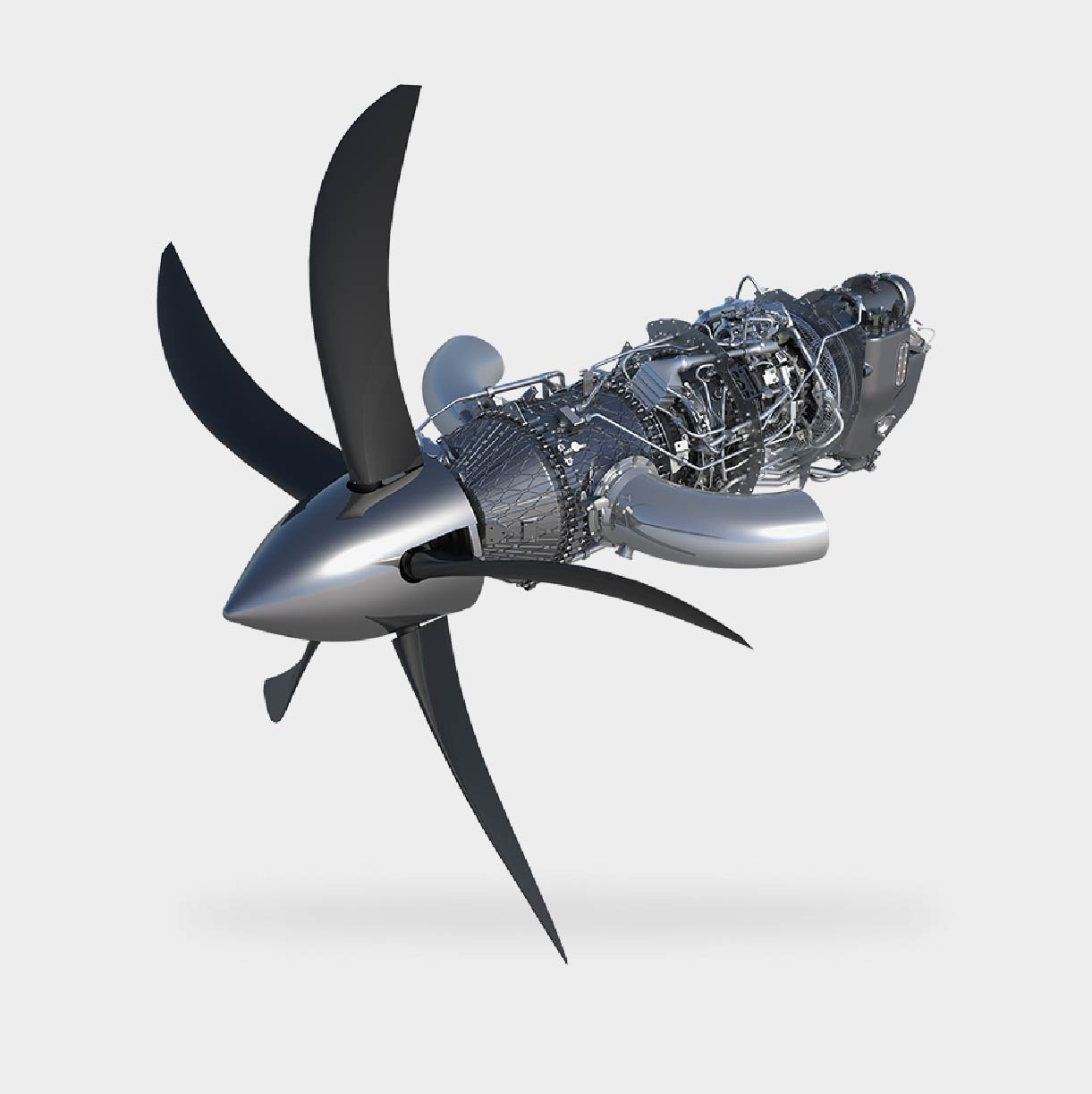

The GE9X is the largest and most powerful commercial aircraft engine ever built, incorporating advanced technologies that enable more efficient, quieter flight with fewer emissions. Designed specifically for the new twin-engine Boeing 777X family, the GE9X is the most fuel-efficient engine in its class, delivering unmatched reliability and performance.

Pounds of thrust

The highest thrust of any commercial jet engine — equivalent 597.396 kN

The GE9X represents a multi-generational technology development chain, supported by millions of hours of field experience. We have pulled learnings from other engines, including the GE90 and GEnx, to enable a more efficient, more reliable, quieter engine with lower emissions.

Combined with the Boeing 777X, the GE9X delivers the best airline economics and profitability via reduced fuel consumption, emissions, and associated costs, and lowest environmental impact.

Larger than a Boeing 737 fuselage, the GE9X fan diameter enables a higher bypass ratio for maximum efficiency.

The GE9X has six less fan blades than the GE90 engine. This maximizes air flow and minimizes drag, contributing to the engine's fuel burn and noise emission advantages.

Expanded use of epoxy resin composites verse the GE90 is used for lighter weight and improved fatigue durability.

The strength of conventional parts

less cooling air needed

The GE9X features the same world-class reliability as the GE90-115B, with noise and NOx emissions well below anticipated regulation standards.

GE9X received FAA certification in September 2020

The GE9X has been through the most rigorous testing program of any GE commercial aircraft engine in history. The engine has now passed through 27,000 cycles and 17,000 hours of testing. That includes a total of 1,600 cycles of dust-ingestion tests.

The GE9X during the third phase testing at our test facility in Peebles, Ohio

Yes, we retrofit legacy systems (e.g., GE Frame 5, Siemens V94.2) with modern digital controllers, typically completing hardware integration within 4-8 weeks. Software migration requires additional validation time.

We recommend annual performance testing under ISO 3977-2 standards. Critical applications (e.g., offshore platforms) may require semi-annual tests with emissions compliance checks.

All rad-hard devices (e.g., FPGA, ADC) are QML Class V certified under MIL-PRF-38535 and tested to MIL-STD-883 Method 1019 for SEU tolerance. Full qualification reports are available upon request.

Our ASICs and power management ICs operate across -55°C to +175°C ambient temperatures, with derating curves provided in military temperature range (MTR) datasheets.

Our PMA parts (e.g., actuators, sensors) hold FAA/EASA Form 1 certification and match OEM form/fit/function. Installation requires SB/MB documentation per FAA AC 23.1529.

All NAS/MS fasteners include full DNA traceability: melt source (AMS 2301), heat/lot numbers, and AS9100-compliant MTRs with ultrasonic test reports.

AOG orders ship within 4 hours for stocked items (FAA-PMA, EASA Part 21G). Non-stock critical parts trigger priority manufacturing with 72-hour max turnaround.

Gas Turbine

Gas Turbine

Aircraft parts

Aircraft parts