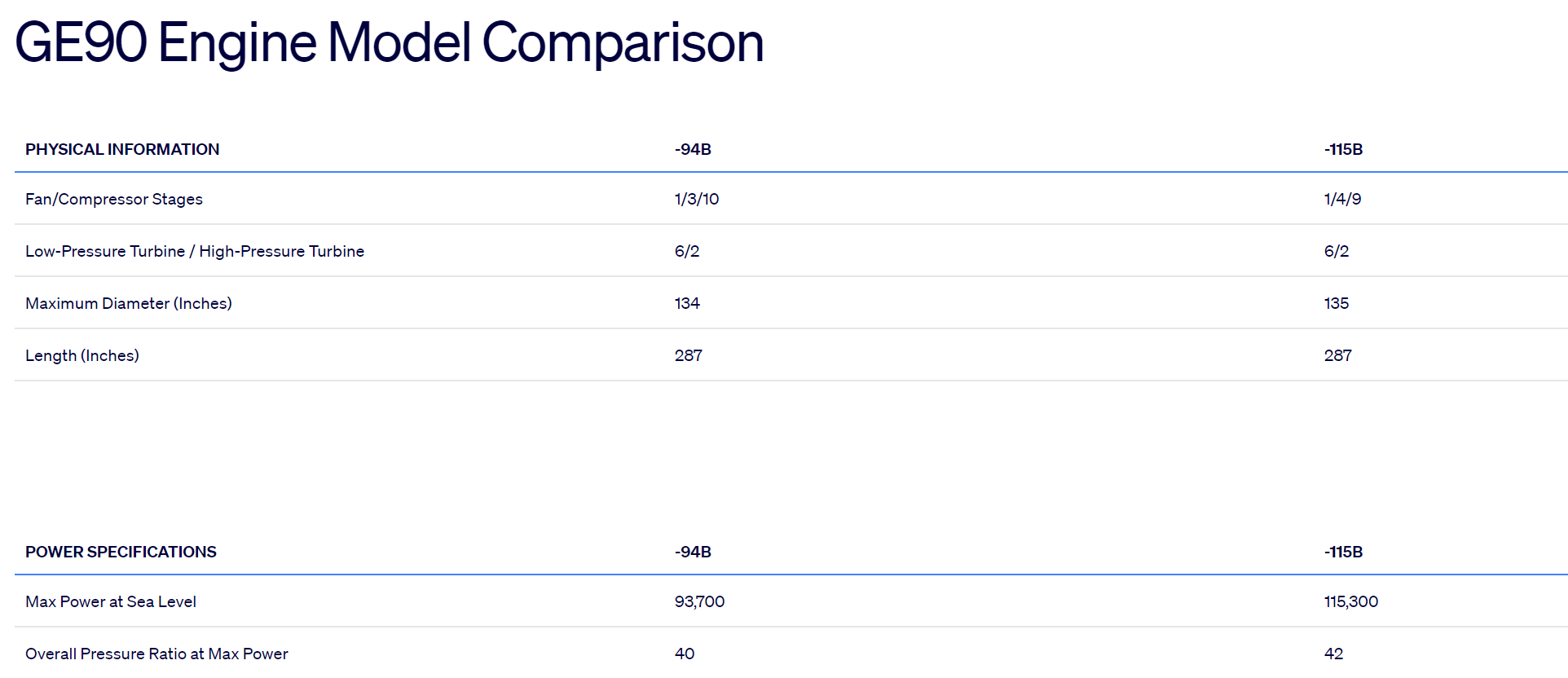

Launched in 1990, the GE90 engine is GE Aerospace’s first engine in the 100,000-pound thrust class and became the most technologically advanced commercial turbofan engine in 25 years.

Groundbreaking firsts

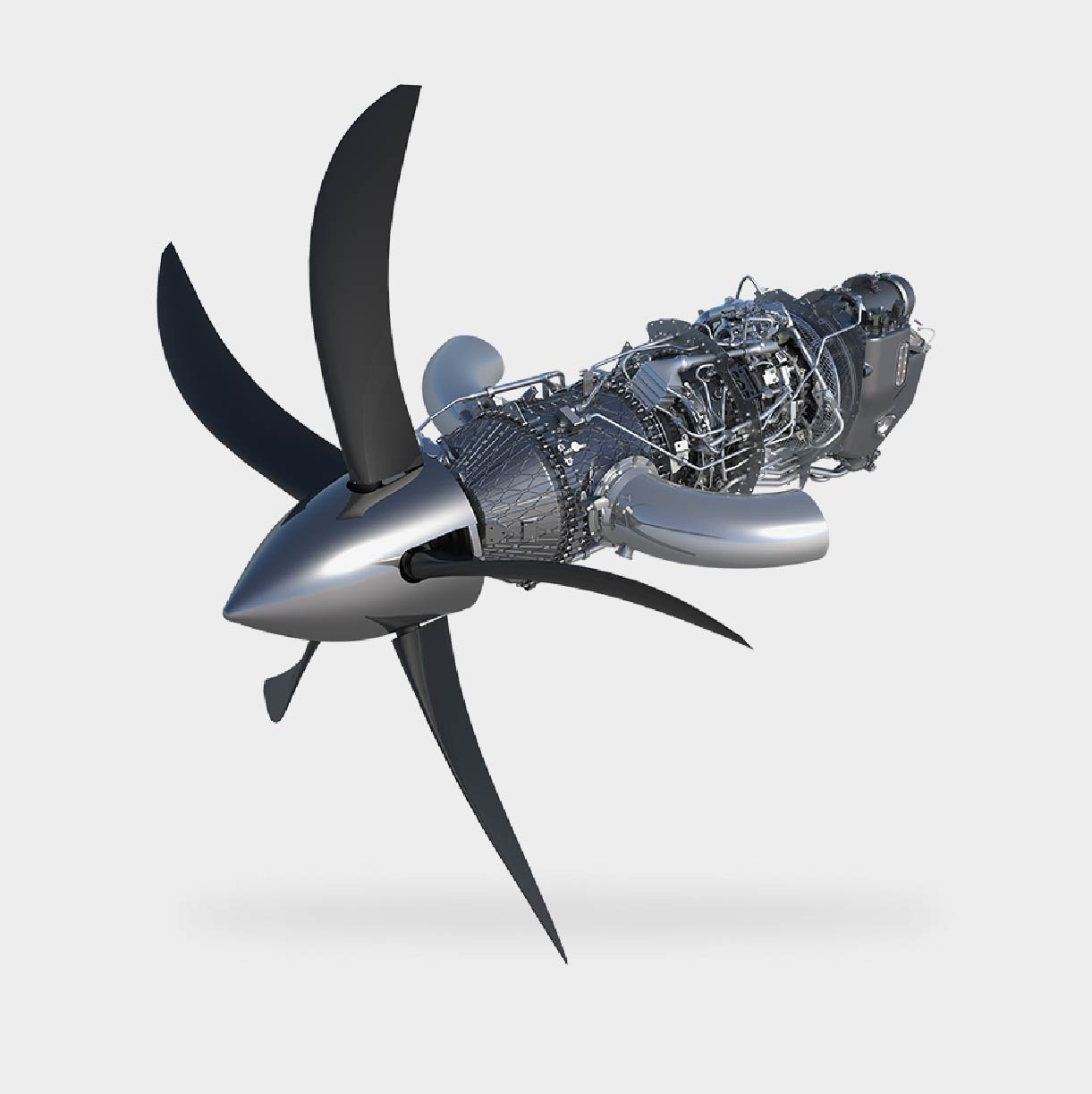

Powering the twin-engine Boeing 777 aircraft, the GE90 engine combined record thrust and high reliability with lower noise, emissions, and fuel consumption to become an iconic jet engine recognized worldwide for its size and innovations.

GE Aerospace has continued to invest and improve the engine. GE Aerospace engineers have enhanced the GE90-115B engine’s compressor, combustor, and high- and low-pressure turbine components to reduce weight, improve fuel efficiency, and enhance durability.

Service anywhere

you need care

With more than 2,800 GE90 engines delivered around the world, GE Aerospace and its global network of maintenance, repair, and overhaul (MRO) providers are anywhere that our customers need support. Through GE Aerospace’s TrueChoice engine services suite, GE90 operators have access to MRO options that can optimize the engine to meet a desired life cycle with targeted workscopes, optimizing hardware utilization and minimizing cost of ownership.

Rated at 94,000 lbs. of thrust, the GE90-94B engine builds on the proven success of the early GE90 engine models to power the Boeing 777-200 and 777-300 aircraft.

After being selected by Boeing to develop an engine with 110,000 to 115,000 lbs. of thrust, GE Aerospace delivered the GE90-115B engine, which now powers the longer-range Boeing 777-200LR, 777-300ER, and 777 Freighter aircraft.

Yes, we retrofit legacy systems (e.g., GE Frame 5, Siemens V94.2) with modern digital controllers, typically completing hardware integration within 4-8 weeks. Software migration requires additional validation time.

We recommend annual performance testing under ISO 3977-2 standards. Critical applications (e.g., offshore platforms) may require semi-annual tests with emissions compliance checks.

All rad-hard devices (e.g., FPGA, ADC) are QML Class V certified under MIL-PRF-38535 and tested to MIL-STD-883 Method 1019 for SEU tolerance. Full qualification reports are available upon request.

Our ASICs and power management ICs operate across -55°C to +175°C ambient temperatures, with derating curves provided in military temperature range (MTR) datasheets.

Our PMA parts (e.g., actuators, sensors) hold FAA/EASA Form 1 certification and match OEM form/fit/function. Installation requires SB/MB documentation per FAA AC 23.1529.

All NAS/MS fasteners include full DNA traceability: melt source (AMS 2301), heat/lot numbers, and AS9100-compliant MTRs with ultrasonic test reports.

AOG orders ship within 4 hours for stocked items (FAA-PMA, EASA Part 21G). Non-stock critical parts trigger priority manufacturing with 72-hour max turnaround.

Gas Turbine

Gas Turbine

Aircraft parts

Aircraft parts