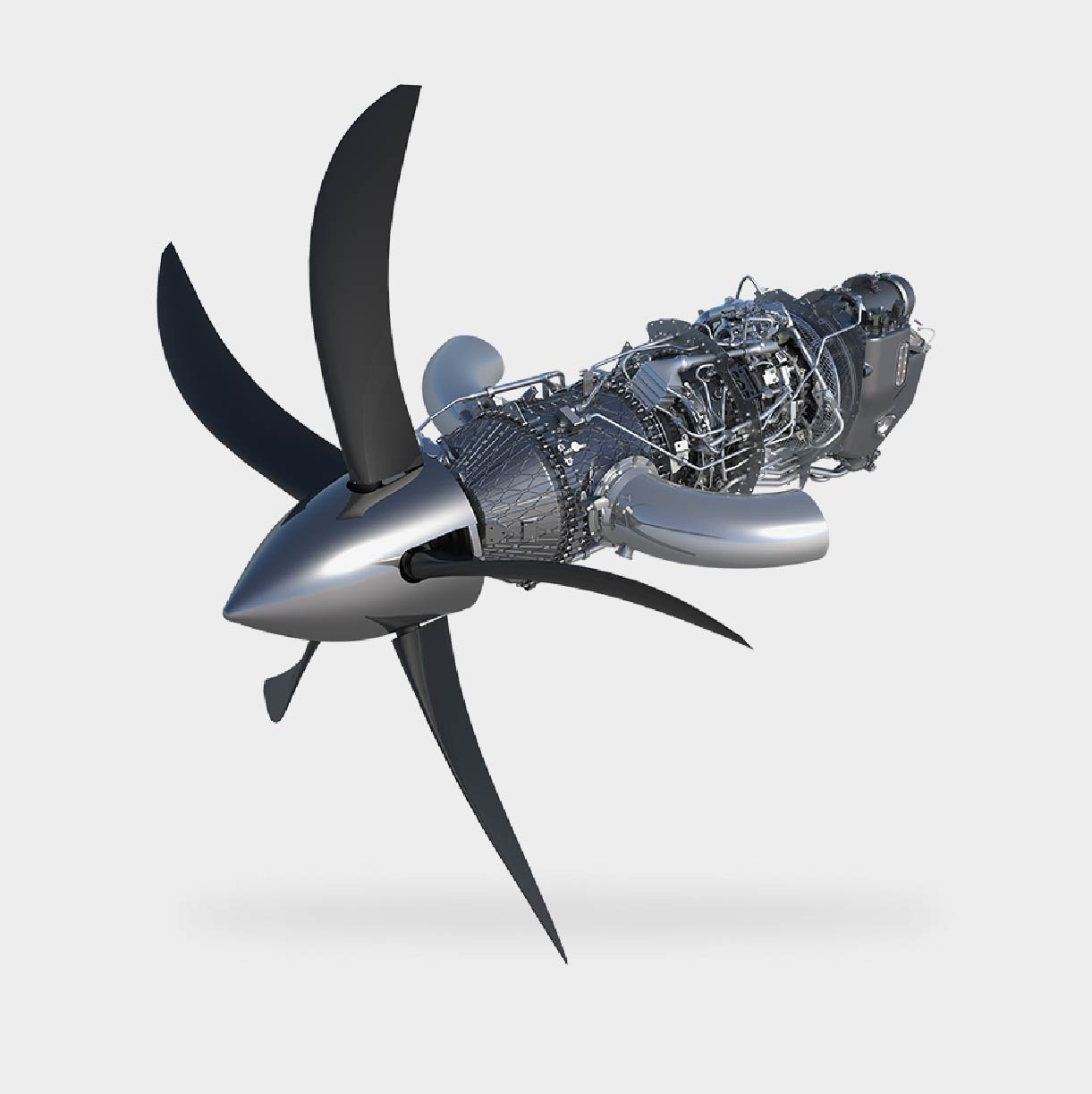

From corporate to charter operators, from skydiving to medical support and cargo transport, H-Series engine – a product of Avio Aero, a GE Aerospace company – is renowned for its reliability. The H-Series thrives in rugged conditions that require mission readiness, short takeoffs, weight variability and safe operation: in the hottest deserts, over the highest peaks and across the most remote archipelagos. Available in a range from 550 to 850 SHP, this turboprop engine family’s configuration allows seamless integration into a variety of airframe types.

The H-Series engine is a two-shaft, reverse flow engine with a free turbine, available with first-in-class Electronic Engine and Propeller Control (EEPC). The engine has an axial compressor and compressor turbine featuring 3D geometry design. Fuel is distributed to the chamber via the slinger ring combustor architecture, which simplifies maintenance and eliminates the need for recurrent fuel nozzle inspections. The propulsion section is powered by a single-stage turbine driving a two-stage planetary gearbox.

The EEPC system, featuring fully integrated engine and propeller operations, provides safer operation and reduces pilot workload by simplifying engine operation with a single lever power control that enhances engine operability. An Aerobatic version of H-Series engine, with a unique multi attitude lubrification system designed to enable flight with zero gravity and strengthened structure for demanding aerobatic maneuvers is undergoing final development tests.

From a pilot’s reduced workload in the cockpit to reduced engine noise in the cabin and industry-leading predictive engine analytics, airframers, passengers, and crew fly with confidence.

GE Aerospace’s reliability and infused technology mean airlines and charter operators can fly on time and avoid maintenance that may otherwise take engines out of service. H-Series engines have no fuel nozzles and no hot section inspections, easing the burden of additional maintenance.

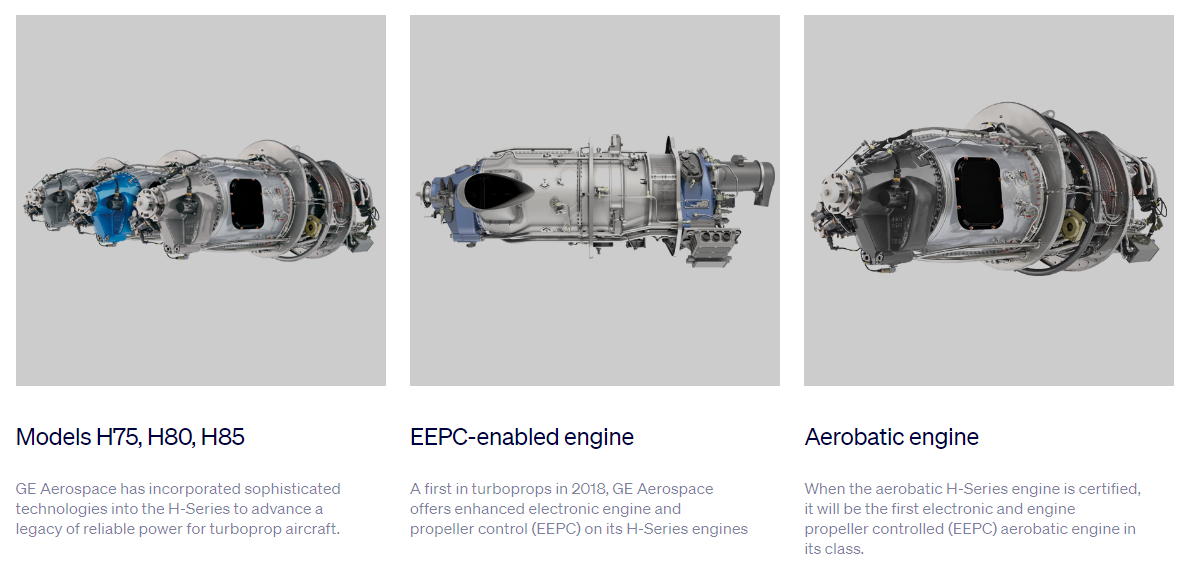

GE Aerospace and Avio Aero have incorporated sophisticated technologies into the H-Series family models - H75, H80 and H85 - to advance a legacy of reliable power for turboprop aircraft.

H-Series service centers

The H-Series engine’s unique design provides more than just performance. With no fuel nozzles, it requires no hot section inspection and minimal maintenance between overhauls. This means operators can devote more time to their missions in the air. When customers do need assistance, GE Aerospace’s field service and customer support teams are available 24/7 and are backed by a global network of 22 authorized service centers across 12 countries, making repairs local and expedient. GE Aerospace offers two locations for overhaul: Prague, GE Aerospace’s production site, or Prime Turbines, GE Aerospace’s authorized repair and overhaul center in Texas.

Yes, we retrofit legacy systems (e.g., GE Frame 5, Siemens V94.2) with modern digital controllers, typically completing hardware integration within 4-8 weeks. Software migration requires additional validation time.

We recommend annual performance testing under ISO 3977-2 standards. Critical applications (e.g., offshore platforms) may require semi-annual tests with emissions compliance checks.

All rad-hard devices (e.g., FPGA, ADC) are QML Class V certified under MIL-PRF-38535 and tested to MIL-STD-883 Method 1019 for SEU tolerance. Full qualification reports are available upon request.

Our ASICs and power management ICs operate across -55°C to +175°C ambient temperatures, with derating curves provided in military temperature range (MTR) datasheets.

Our PMA parts (e.g., actuators, sensors) hold FAA/EASA Form 1 certification and match OEM form/fit/function. Installation requires SB/MB documentation per FAA AC 23.1529.

All NAS/MS fasteners include full DNA traceability: melt source (AMS 2301), heat/lot numbers, and AS9100-compliant MTRs with ultrasonic test reports.

AOG orders ship within 4 hours for stocked items (FAA-PMA, EASA Part 21G). Non-stock critical parts trigger priority manufacturing with 72-hour max turnaround.

Gas Turbine

Gas Turbine

Aircraft parts

Aircraft parts