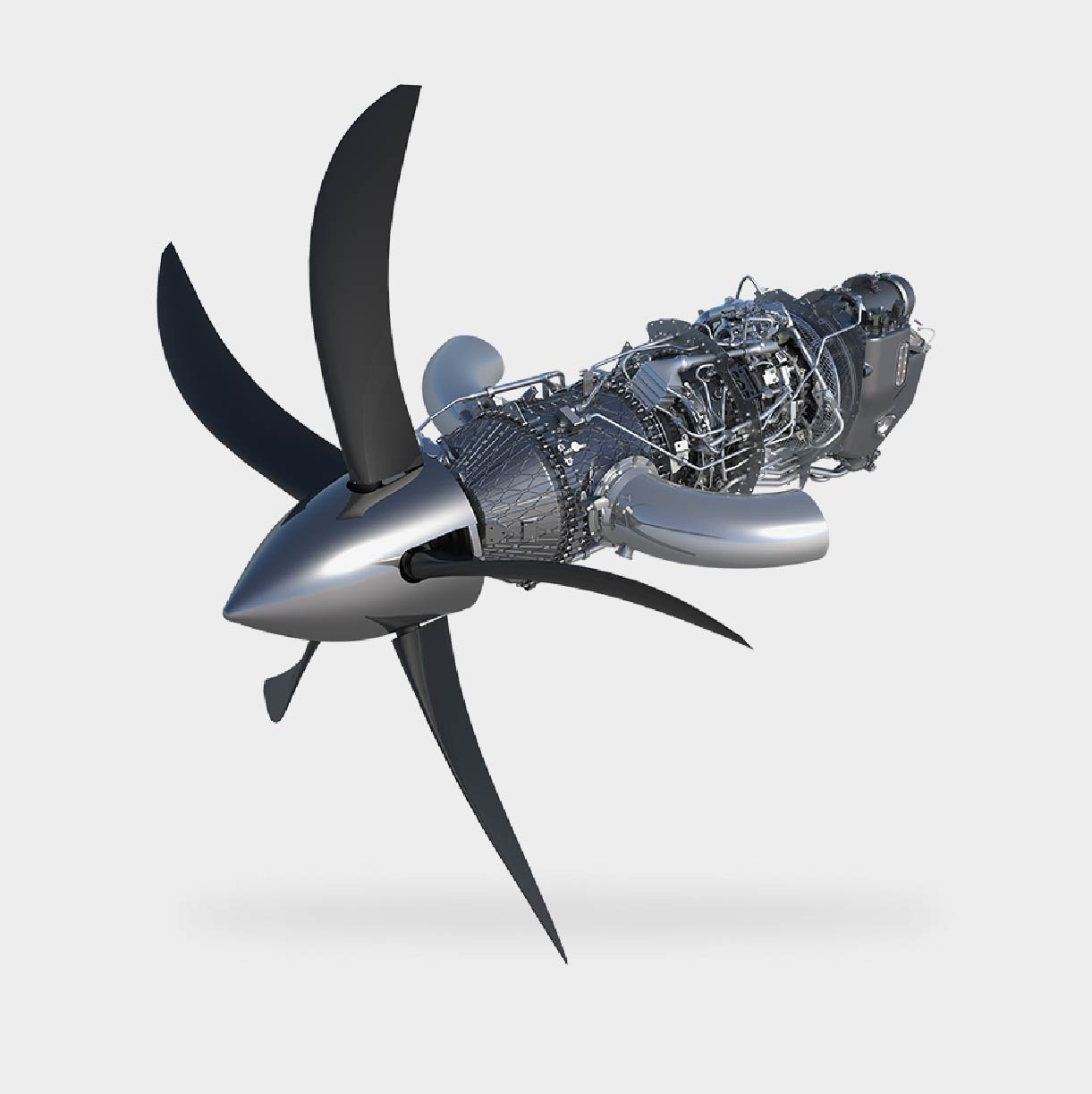

With more than 100 million flight hours, GE’s CT7/T700 family of turboshaft and turboprop engines operates across the globe in every environment your aircraft travels.

Longer time on wing

A truly modular engine designed for ease of

maintenance and reduced operating costs requiring no time between overhauls (TBO)

Flexible

CT7

TrueChoice Flight Hour service program

Providing the best products and services to help you meet operational and ownership expectations, GE’s TrueChoice Flight Hour delivers a range of options from all-inclusive care to more self-managed programs.

Basic

The most cost-effective offering for customers prepared to exchange potential variable expenses for the lowest fixed per hour rate GE has available.

- Scheduled and unscheduled shop visits

- Labor and material other than life-limited parts (LLP)

- Lease engine usage fee

- Flight hour rate

- Plus daily rent

- LLP restoration

- Engine monitoring

STANDARD

Designed to ensure customer overhaul expenses are covered and predictable while allowing the customer to exchange moderate levels of variable cost for a lower fixed cost per hour rate.

- Scheduled and unscheduled shop visits

- All labor and material

- Lease engine usage fee

- Flight hour rate

- Plus daily rent

- Engine monitoring

SELECT

The best-value service offering for customers desiring a fixed and predictable cost structure while retaining lower probability of variable cost and a more manageable fixed price per hour rate.

- Scheduled and unscheduled shop visits

- All labor and material

- Lease engine usage fee

- Flight Hour rate

- Engine monitoring

- Line replacement unit coverage

- Consumable replenishment

- Required service bulletin/ airworthiness directives

- GE’s customer training education center access

COMPREHENSIVE

The all-inclusive service offering for a fixed and predictable cost structure with a low to zero probability of variable expenses.

- Scheduled and unscheduled shop visits

- All labor and material

- Lease engine usage fee

- Flight Hour rate

- Engine monitoring

- Line replacement unit coverage

- Consumable replenishment

- Required service bulletin/ airworthiness directives

- On-site training

- Four-way transportation

- Foreign object damage (FOD) coverage

Transitions

We also offer a transitions package to operators designed to maintain TrueChoice services during the transition period in between operators on a fixed annual fee basis.

T700

TrueChoice service for restricted category

Providing the best products and services to customers to meet operational and ownership expectations, GE’s TrueChoice T700 service programs deliver a range of options from all-inclusive care to more self-managed programs.

Basic

The most cost-effective offering for customers prepared to exchange potential variable expenses for the lowest fixed per hour rate GE has available.

- Scheduled and unscheduled shop visits

- Labor and material other than life-limited parts (LLP)

- Lease engine usage fee

- Flight hour rate

- Plus daily rent

- LLP restoration

- Engine monitoring

STANDARD

Designed to ensure customer overhaul expenses are covered and predictable while allowing the customer to exchange moderate levels of variable cost for a lower fixed cost per hour rate.

- Scheduled and unscheduled shop visits

- All labor and material

- Lease engine usage fee

- Flight hour rate

- Plus daily rent

- Engine monitoring

SELECT

The best-value service offering for customers desiring a fixed and predictable cost structure while retaining lower probability of variable cost and a more manageable fixed price per hour rate.

- Scheduled and unscheduled shop visits

- All labor and material

- Lease engine usage fee

- Flight Hour rate

- Engine monitoring

- Line replacement unit coverage

- Consumable replenishment

- Required service bulletin/ airworthiness directives

- GE’s customer training education center access

COMPREHENSIVE

The all-inclusive service offering for a fixed and predictable cost structure with a low to zero probability of variable expenses.

- Scheduled and unscheduled shop visits

- All labor and material

- Lease engine usage fee

- Flight Hour rate

- Engine monitoring

- Line replacement unit coverage

- Consumable replenishment

- Required service bulletin/ airworthiness directives

- On-site training

- Four-way transportation

- Foreign object damage (FOD) coverage

Transitions

We also offer a transitions package to operators designed to maintain TrueChoice services during the transition period in between operators on a fixed annual fee basis.

GE Aerospace is a world leader in technologies that improve fuel efficiency and reduce emissions.

All of GE’s CT7/T700 engines are among the best in class for specific fuel consumption. All engines are certified to operate on Sustainable Aviation Fuels (SAFs), which will help to reduce the reliance on fossil fuels.

Yes, we retrofit legacy systems (e.g., GE Frame 5, Siemens V94.2) with modern digital controllers, typically completing hardware integration within 4-8 weeks. Software migration requires additional validation time.

We recommend annual performance testing under ISO 3977-2 standards. Critical applications (e.g., offshore platforms) may require semi-annual tests with emissions compliance checks.

All rad-hard devices (e.g., FPGA, ADC) are QML Class V certified under MIL-PRF-38535 and tested to MIL-STD-883 Method 1019 for SEU tolerance. Full qualification reports are available upon request.

Our ASICs and power management ICs operate across -55°C to +175°C ambient temperatures, with derating curves provided in military temperature range (MTR) datasheets.

Our PMA parts (e.g., actuators, sensors) hold FAA/EASA Form 1 certification and match OEM form/fit/function. Installation requires SB/MB documentation per FAA AC 23.1529.

All NAS/MS fasteners include full DNA traceability: melt source (AMS 2301), heat/lot numbers, and AS9100-compliant MTRs with ultrasonic test reports.

AOG orders ship within 4 hours for stocked items (FAA-PMA, EASA Part 21G). Non-stock critical parts trigger priority manufacturing with 72-hour max turnaround.

Gas Turbine

Gas Turbine

Aircraft parts

Aircraft parts