Designed, developed and produced by CFM International, the CFM56 engine powers single-aisle commercial jetliners from Airbus (A320 family) and Boeing (737 family), as well as various military aircraft.

Designed, developed and produced by CFM International, the CFM56 engine powers single-aisle commercial jetliners from Airbus (A320 family) and Boeing (737 family), as well as various military aircraft.

A family of engines that has addressed evolving market demand for more than 40 years.

Dispatch reliability nearly 100% and unrivaled time on wing.

Reduced operating and maintenance costs, thanks to robust design.

With more than 33,000 delivered to date, CFM56® engines mainly power single-aisle commercial jets from Airbus and Boeing. The CFM56®, developing 18,500 to 33,000 lb of thrust, set a standard in this market. It owes its impressive success to exceptional performance and reliability, the result of the two partners' technical excellence. The CFM56® offers dispatch reliability approaching 100%, along with unrivaled time "on-wing" (without removal for servicing) – advantages that help significantly reduce operating costs. To ensure top dispatch reliability for all customers, CFM continues to produce a volume of spare engines and parts.

The reliability and endurance of the CFM56® are just as appreciated in military applications. For example, the U.S. Air Force is CFM's leading customer, deploying more than 2,500 CFM56 engines. The British and French air forces also operate a number of CFM-powered aircraft. In particular, these engines power the KC-135 and C-135FR tankers, the E-3 and E-6 AWACS and early warning aircraft, the Boeing 737 AEW&C, C-40 transports and the P8-A Poseidon maritime patrol aircraft.

The CFM56 engine is the result of a 50/50 partnership between Safran Aircraft Engines and GE Aviation called CFM International. The two companies are equal partners in the design, development and production of the engine. Final assembly, sales and services are performed by each partner using its own resources. Signed in 1974, the CFM International partnership agreement was renewed in 2008 and extended through 2040; it now includes services.

Over 28,000 CFM56 engines are currently in service with commercial and military operators around the world. They benefit from global support and a complete array of services spanning the entire engine lifecycle: on-wing and shop maintenance, parts, repairs, asset management and more.

Yes, we retrofit legacy systems (e.g., GE Frame 5, Siemens V94.2) with modern digital controllers, typically completing hardware integration within 4-8 weeks. Software migration requires additional validation time.

We recommend annual performance testing under ISO 3977-2 standards. Critical applications (e.g., offshore platforms) may require semi-annual tests with emissions compliance checks.

All rad-hard devices (e.g., FPGA, ADC) are QML Class V certified under MIL-PRF-38535 and tested to MIL-STD-883 Method 1019 for SEU tolerance. Full qualification reports are available upon request.

Our ASICs and power management ICs operate across -55°C to +175°C ambient temperatures, with derating curves provided in military temperature range (MTR) datasheets.

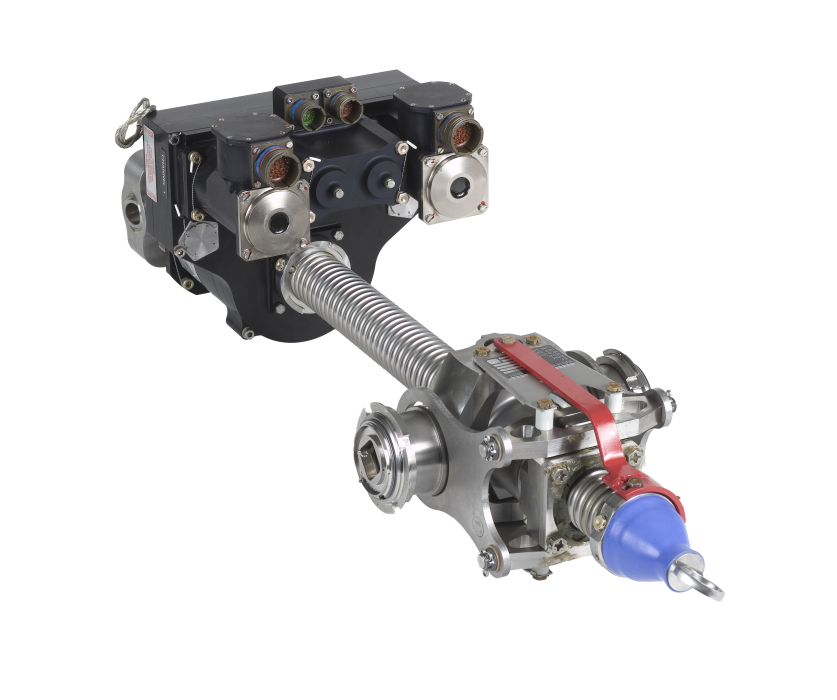

Our PMA parts (e.g., actuators, sensors) hold FAA/EASA Form 1 certification and match OEM form/fit/function. Installation requires SB/MB documentation per FAA AC 23.1529.

All NAS/MS fasteners include full DNA traceability: melt source (AMS 2301), heat/lot numbers, and AS9100-compliant MTRs with ultrasonic test reports.

AOG orders ship within 4 hours for stocked items (FAA-PMA, EASA Part 21G). Non-stock critical parts trigger priority manufacturing with 72-hour max turnaround.

Gas Turbine

Gas Turbine

Aircraft parts

Aircraft parts