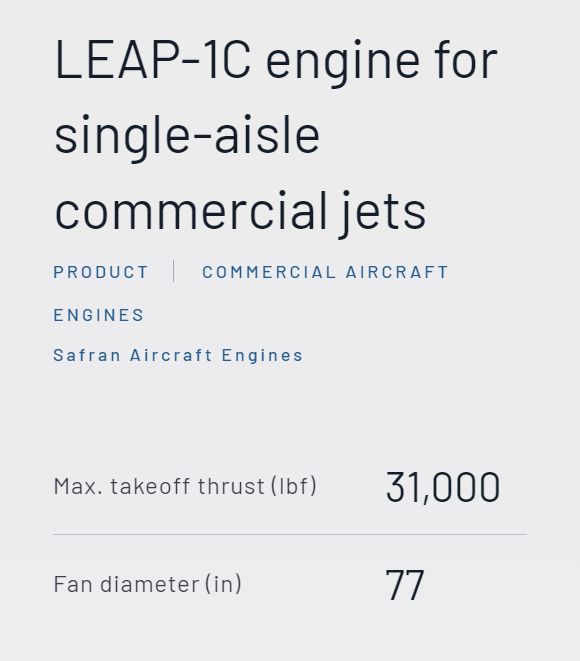

Designed, produced and marketed by CFM International, the LEAP-1C is the only Western engine offered on the COMAC C919, a new-generation single-aisle jet from China.

Designed, produced and marketed by CFM International, the LEAP-1C is the only Western engine offered on the COMAC C919, a new-generation single-aisle jet from China.

15% reduction in fuel consumption and CO2 emissions*

*Compared to previous-generation engines.

Up to 50% reduction in NOx emissions*

*In accordance with the ICAO’s CAEP/6 environmental standard.

Meets the most stringent noise standards (the ICAO’s Chapter 14)

10,000+

orders for LEAP engines (in backlog)

160+

LEAP operators worldwide

60+

million flight hours

Designed to meet the challenge of decarbonizing air transport, the LEAP-1C engine offers COMAC C919 operators enhanced performance in terms of fuel consumption and CO2 emissions (15% lower1), NOx emissions (up to 50% lower2) and noise (in accordance with Chapter 14).

1. Compared to previous-generation engines.2. In accordance with the ICAO’s CAEP/6 environmental standard.

The LEAP-1C engine benefits from the latest innovations in materials and production processes.

To achieve its remarkable performance, the LEAP-1C is packed with innovative technologies and materials. The use of a 3D woven composite material and the RTM (resin transfer molding) process developed and patented by Safran Aircraft Engines makes it possible to produce fan blades that are lighter, stronger and more durable. The low-pressure turbine blades are machined from an innovative titanium-aluminide alloy that is lighter and more resistant to high temperatures. The low-pressure turbine rings and airfoils are made of CMC (ceramic matrix composite) materials and the fuel injectors are 3D printed.

Thanks to Factory 4.0 facilities and unique processes, Safran Aircraft Engines has achieved a production ramp-up that is unprecedented in commercial aviation history. The LEAP engine final assembly line in Villaroche, near Paris, has earned the “Showcase for the Industry of the Future” label in France.

With the LEAP’s success, Safran Aircraft Engines has set up a powerful logistics organization to meet strong customer demand. Its supply chain calls on more than 150 direct suppliers in 14 countries. Building on a long-term partnership approach, Safran Aircraft Engines helps suppliers continuously improve their operational performance in terms of quality, costs and lead times. This organization has largely contributed to the success of the production ramp-up.

Established in 1974, CFM International is a 50/50 joint company between Safran Aircraft Engines and GE. This partnership, now extended to 2050, has spawned the best-selling engine in commercial aviation history, the CFM56, and its successor, the LEAP. Today, CFM International is the global market leader in engines for mainline commercial jets (over 100 seats). Safran Aircraft Engines and GE are equal partners in the design, development, production, sale and support of all versions of the LEAP. Final assembly is performed at both GE facilities in the United States and Safran Aircraft Engines facilities in France.

Through CFM Services, Safran Aircraft Engines provides LEAP-1C customers with a wide range of services tailored to each one’s business model and evolving fleet size, including time & material contracts, support-by-the-hour contracts and customized support solutions. These services are delivered through a dozen MRO centers worldwide, which together employ over 3,000 people, more than half of them based internationally in close proximity to operators. This gives operators a high degree of fleet management flexibility and greater control over their long-term maintenance expenses.

Yes, we retrofit legacy systems (e.g., GE Frame 5, Siemens V94.2) with modern digital controllers, typically completing hardware integration within 4-8 weeks. Software migration requires additional validation time.

We recommend annual performance testing under ISO 3977-2 standards. Critical applications (e.g., offshore platforms) may require semi-annual tests with emissions compliance checks.

All rad-hard devices (e.g., FPGA, ADC) are QML Class V certified under MIL-PRF-38535 and tested to MIL-STD-883 Method 1019 for SEU tolerance. Full qualification reports are available upon request.

Our ASICs and power management ICs operate across -55°C to +175°C ambient temperatures, with derating curves provided in military temperature range (MTR) datasheets.

Our PMA parts (e.g., actuators, sensors) hold FAA/EASA Form 1 certification and match OEM form/fit/function. Installation requires SB/MB documentation per FAA AC 23.1529.

All NAS/MS fasteners include full DNA traceability: melt source (AMS 2301), heat/lot numbers, and AS9100-compliant MTRs with ultrasonic test reports.

AOG orders ship within 4 hours for stocked items (FAA-PMA, EASA Part 21G). Non-stock critical parts trigger priority manufacturing with 72-hour max turnaround.

Gas Turbine

Gas Turbine

Aircraft parts

Aircraft parts