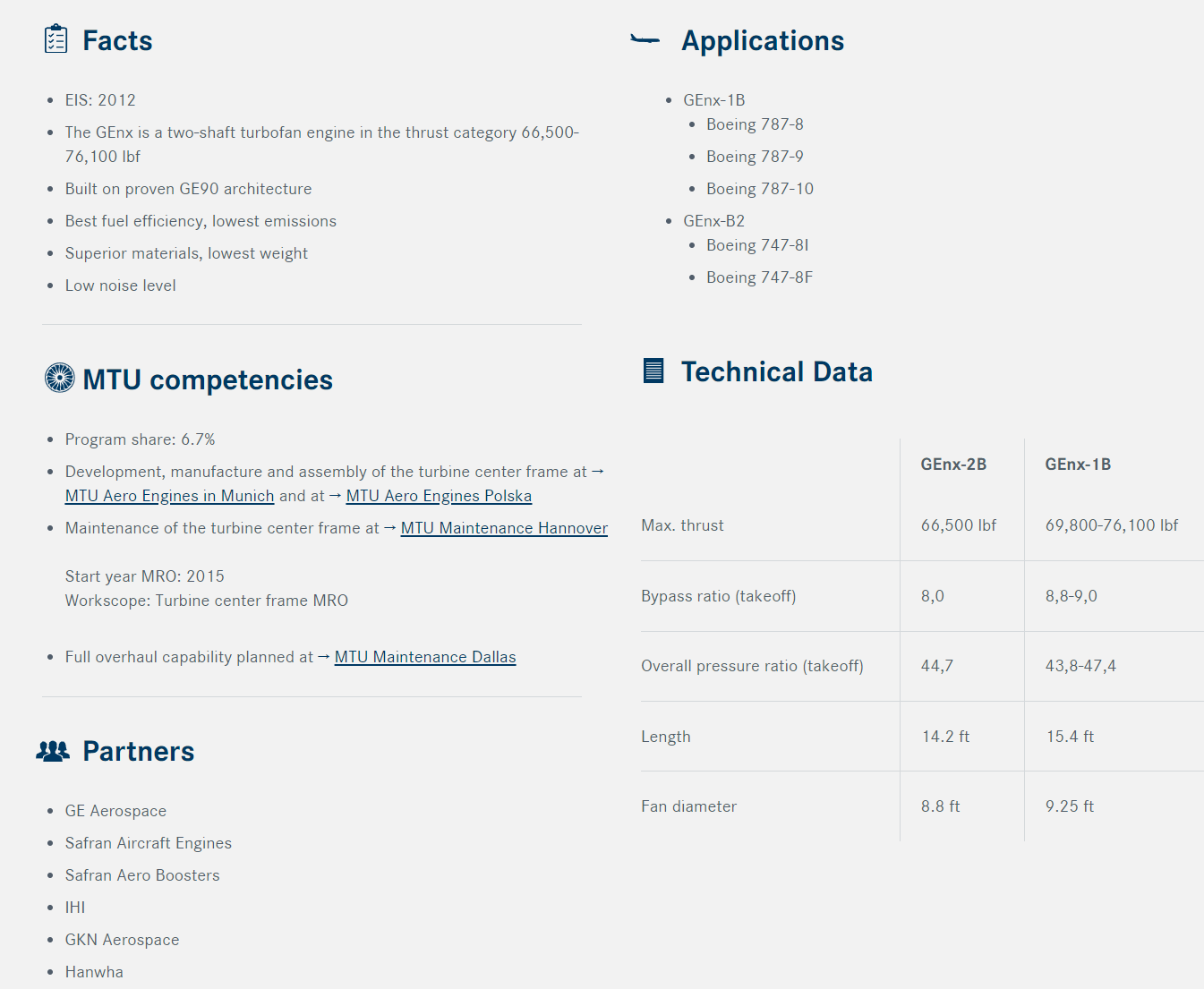

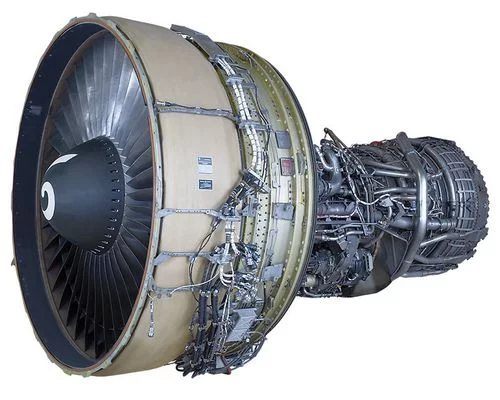

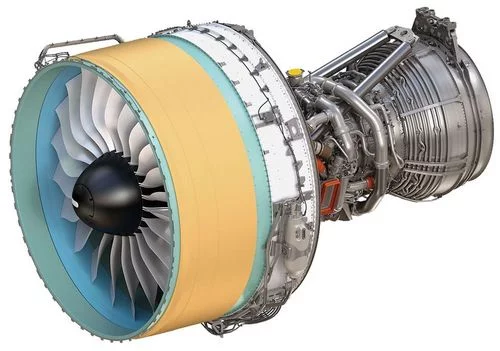

The GEnx engine from GE is based on the proven architecture of the GE90. The GEnx-1B version was designed for medium-capacity widebody aircraft such as the Boeing 787 Dreamliner, while the GEnx-2B version was developed for the Boeing 747-8—the uprated version of the legendary Boeing 747 “Queen of the Skies.” The GEnx was designed to succeed the massively successful CF6, the best-selling engine for widebody aircraft. Using the latest materials and design techniques, GE succeeded in reducing the engine’s weight, noise emissions, and maintenance costs while also enhancing performance.

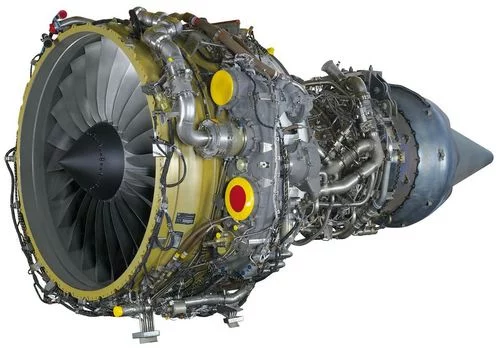

MTU is a risk- and revenue-sharing partner in the GEnx program with a share of around 6.7 percent. The company is responsible for developing, manufacturing, and assembling the turbine center frame. Here, MTU can draw on its experience with the turbine center frame for the GP7000, which is testament to this component’s reliability. As per MTU’s involvement in the program, MTU Maintenance is responsible for maintaining this turbine center frame.

MTU will also be introducing full overhaul capability for GEnx engines at its facility MTU Maintenance Dallas. The new long-term GE Aerospace Branded Services Agreement (GBSA) enables MTU Maintenance Dallas to serve as an authorized service provider for GEnx engines with highest level of training and support, as well as greater access to proprietary overhaul and repair technology.

Yes, we retrofit legacy systems (e.g., GE Frame 5, Siemens V94.2) with modern digital controllers, typically completing hardware integration within 4-8 weeks. Software migration requires additional validation time.

We recommend annual performance testing under ISO 3977-2 standards. Critical applications (e.g., offshore platforms) may require semi-annual tests with emissions compliance checks.

All rad-hard devices (e.g., FPGA, ADC) are QML Class V certified under MIL-PRF-38535 and tested to MIL-STD-883 Method 1019 for SEU tolerance. Full qualification reports are available upon request.

Our ASICs and power management ICs operate across -55°C to +175°C ambient temperatures, with derating curves provided in military temperature range (MTR) datasheets.

Our PMA parts (e.g., actuators, sensors) hold FAA/EASA Form 1 certification and match OEM form/fit/function. Installation requires SB/MB documentation per FAA AC 23.1529.

All NAS/MS fasteners include full DNA traceability: melt source (AMS 2301), heat/lot numbers, and AS9100-compliant MTRs with ultrasonic test reports.

AOG orders ship within 4 hours for stocked items (FAA-PMA, EASA Part 21G). Non-stock critical parts trigger priority manufacturing with 72-hour max turnaround.

Gas Turbine

Gas Turbine

Aircraft parts

Aircraft parts