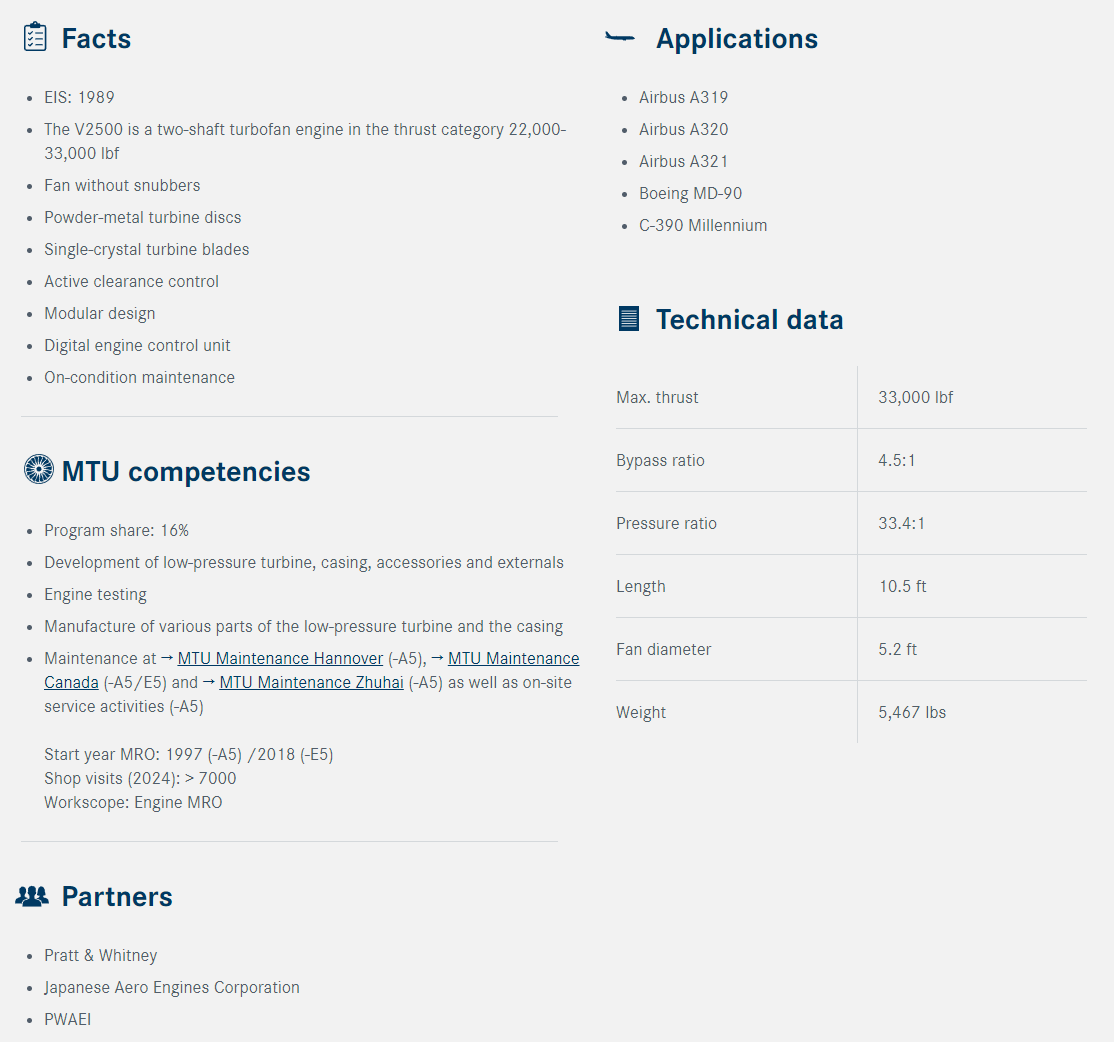

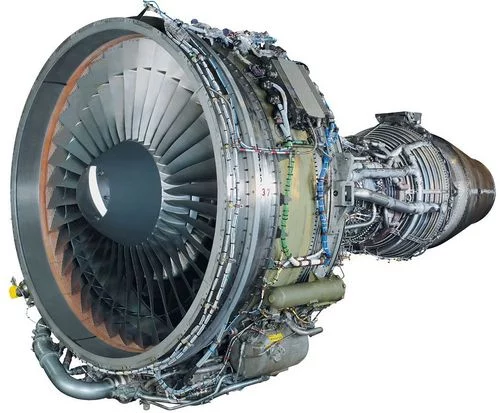

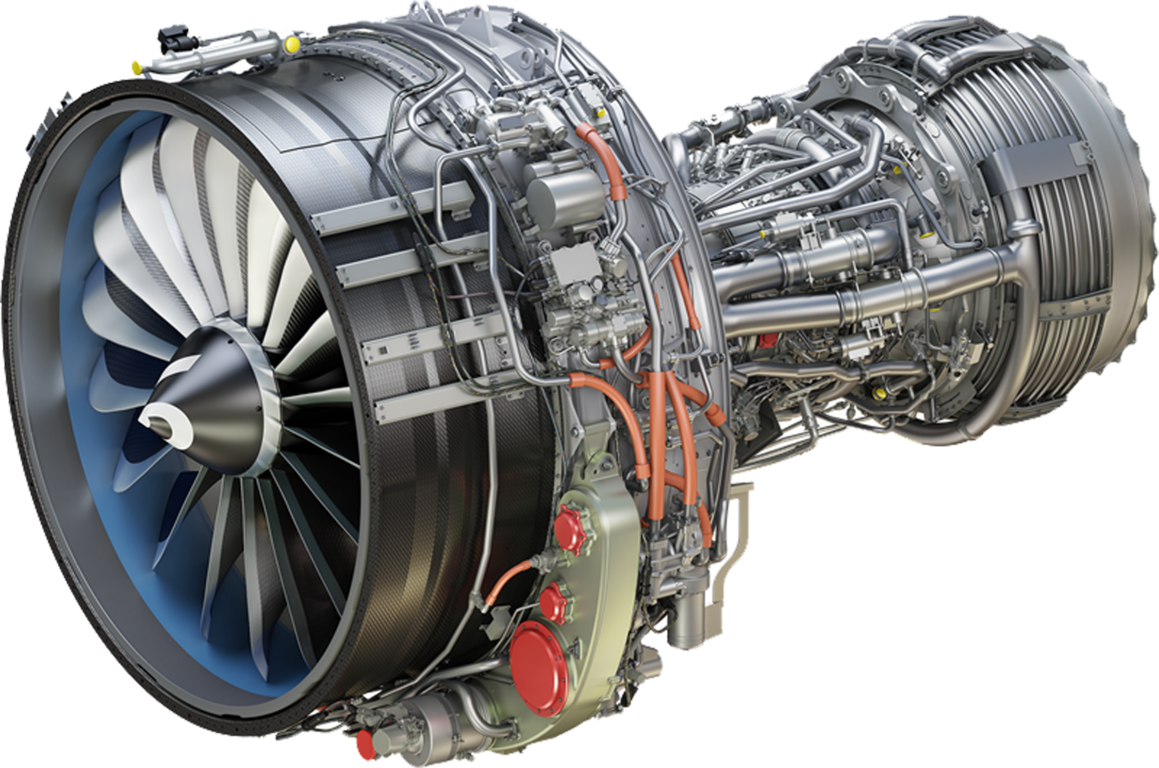

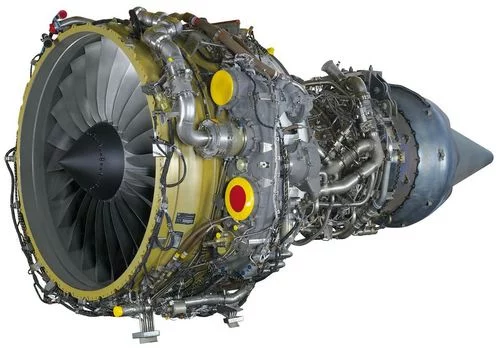

The IAE V2500 is a two-shaft turbofan engine specially designed for narrowbody aircraft. It is used to power a number of aircraft, including the Airbus A319, A320, and A321. A major advancement on this engine, the IAE V2500Select-One™, was introduced in September 2008. Compared to the V2500-A5, this version offers a 1 percent drop in fuel consumption and achieves a 20 percent increase in on-wing operating time. The V2500-E5 is the engine version for the Embraer C-390 transport aircraft.

MTU has a 16 percent share in the IAE V2500 and is responsible for the entire low-pressure turbine as well as for numerous accessories. The development and manufacture of the IAE V2500 is in collaboration with Pratt & Whitney and the Japanese Aero Engines Corporation. To market the engines, a joint venture—International Aero Engines AG (IAE)—was founded in 1983.

To date, this engine fleet has completed more than 280 million flight hours. Repairs to the V2500-A5 and V2500-E5 models is handled by MTU Maintenance, which offers the full range of maintenance and overhaul services. This also includes extensive repair capabilities.

Yes, we retrofit legacy systems (e.g., GE Frame 5, Siemens V94.2) with modern digital controllers, typically completing hardware integration within 4-8 weeks. Software migration requires additional validation time.

We recommend annual performance testing under ISO 3977-2 standards. Critical applications (e.g., offshore platforms) may require semi-annual tests with emissions compliance checks.

All rad-hard devices (e.g., FPGA, ADC) are QML Class V certified under MIL-PRF-38535 and tested to MIL-STD-883 Method 1019 for SEU tolerance. Full qualification reports are available upon request.

Our ASICs and power management ICs operate across -55°C to +175°C ambient temperatures, with derating curves provided in military temperature range (MTR) datasheets.

Our PMA parts (e.g., actuators, sensors) hold FAA/EASA Form 1 certification and match OEM form/fit/function. Installation requires SB/MB documentation per FAA AC 23.1529.

All NAS/MS fasteners include full DNA traceability: melt source (AMS 2301), heat/lot numbers, and AS9100-compliant MTRs with ultrasonic test reports.

AOG orders ship within 4 hours for stocked items (FAA-PMA, EASA Part 21G). Non-stock critical parts trigger priority manufacturing with 72-hour max turnaround.

Gas Turbine

Gas Turbine

Aircraft parts

Aircraft parts