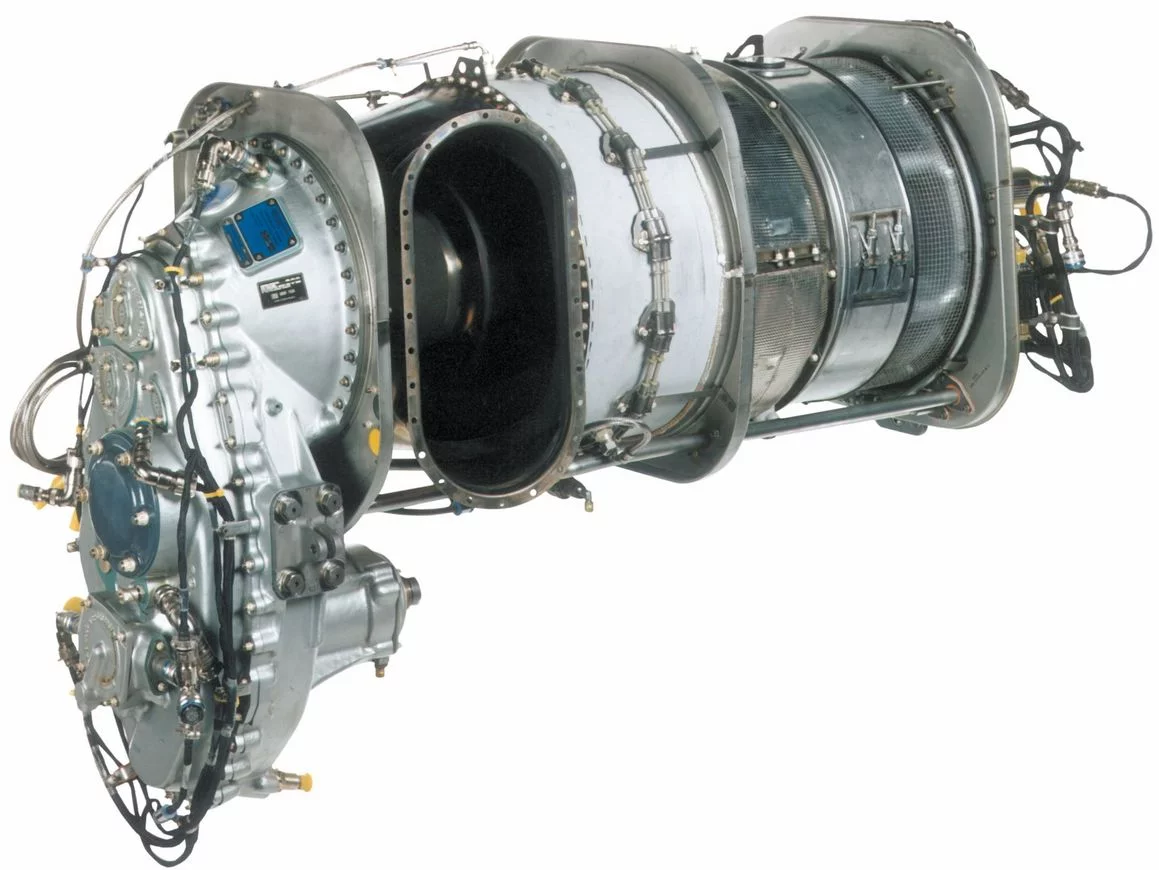

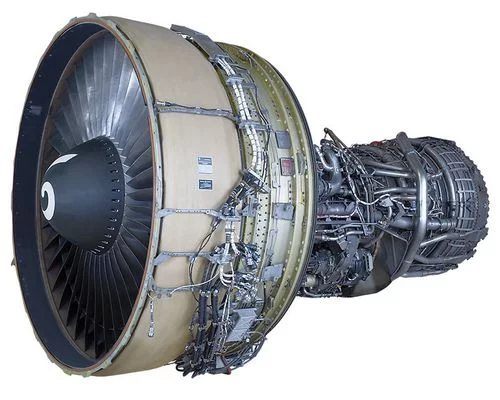

The LEAP engine family from CFM International—a consortium comprising GE Aerospace and Safran Aircraft Engines—includes three different models covering a thrust range from 23,000 to 35,000 pounds. Among the aircraft they power are the Airbus A320neo and the Boeing 737 MAX. Some 7,000 LEAP-1A and LEAP-1B engines have been delivered to date, and a further 20,000 orders and commitments to buy have been received.

Maintenance of the LEAP-1A and LEAP-1B models is performed by MTU Maintenance Zhuhai. This site offers short-notice service slots and short turnaround times at competitive prices, which affords airlines the planning flexibility they need in today’s market situation. The Zhuhai location has EASA, FAA, CAAC, and other certifications for this engine model and is ideally positioned at one of Asia’s major hubs.

Additionally, MTU Maintenance Dallas will be one of only six exclusive Premier MRO service providers for LEAP engines in the world. The classification as Premier MRO enables MTU to offer full performance restoration and extensive repair capabilities for CFM LEAP engines. MTU Maintenance’s facility in Fort Worth is working on meeting all requirements for LEAP engine inductions in the coming years.

In addition, through MTU Maintenance Lease Services B.V. in Amsterdam, MTU offers a range of engine leasing options.

Yes, we retrofit legacy systems (e.g., GE Frame 5, Siemens V94.2) with modern digital controllers, typically completing hardware integration within 4-8 weeks. Software migration requires additional validation time.

We recommend annual performance testing under ISO 3977-2 standards. Critical applications (e.g., offshore platforms) may require semi-annual tests with emissions compliance checks.

All rad-hard devices (e.g., FPGA, ADC) are QML Class V certified under MIL-PRF-38535 and tested to MIL-STD-883 Method 1019 for SEU tolerance. Full qualification reports are available upon request.

Our ASICs and power management ICs operate across -55°C to +175°C ambient temperatures, with derating curves provided in military temperature range (MTR) datasheets.

Our PMA parts (e.g., actuators, sensors) hold FAA/EASA Form 1 certification and match OEM form/fit/function. Installation requires SB/MB documentation per FAA AC 23.1529.

All NAS/MS fasteners include full DNA traceability: melt source (AMS 2301), heat/lot numbers, and AS9100-compliant MTRs with ultrasonic test reports.

AOG orders ship within 4 hours for stocked items (FAA-PMA, EASA Part 21G). Non-stock critical parts trigger priority manufacturing with 72-hour max turnaround.

Gas Turbine

Gas Turbine

Aircraft parts

Aircraft parts