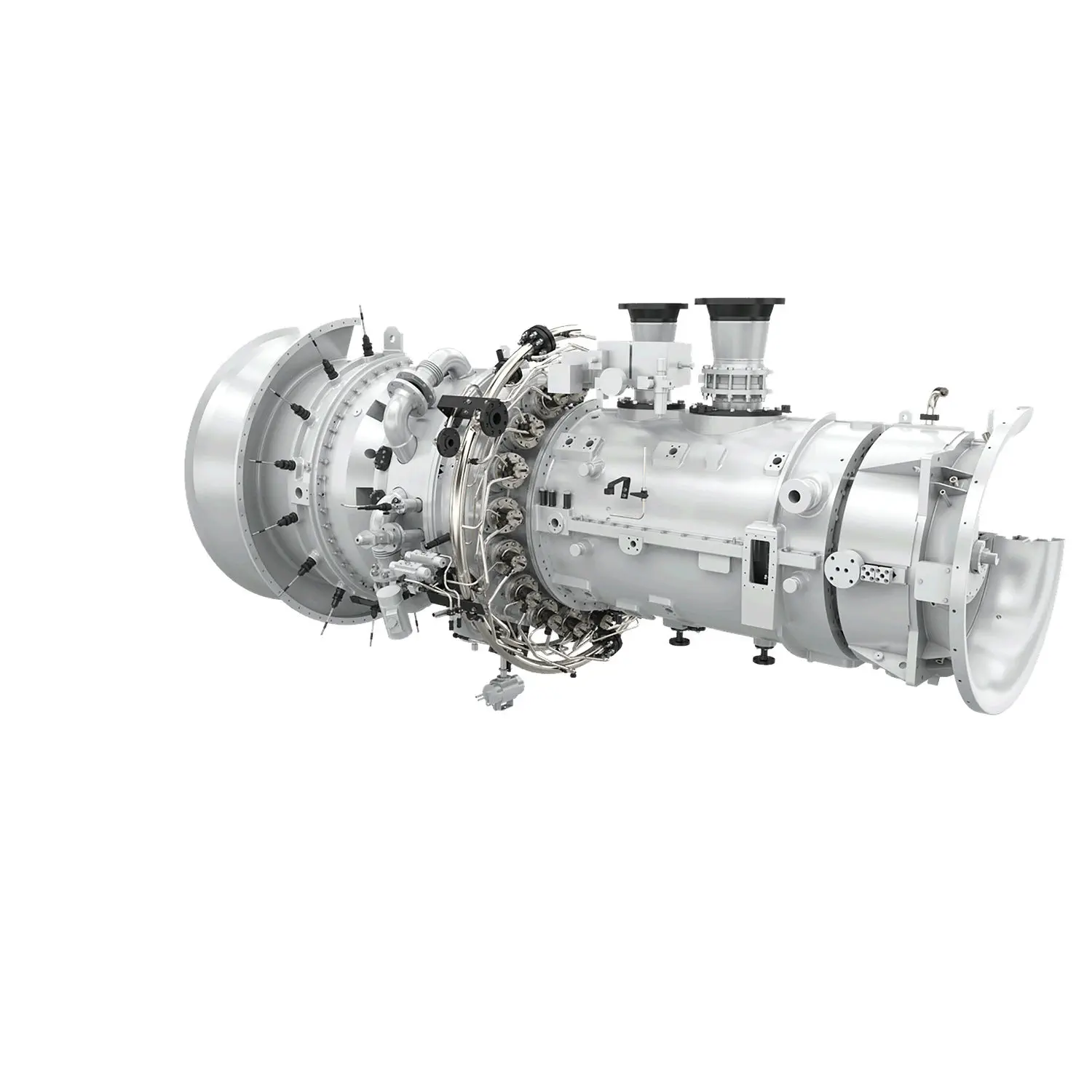

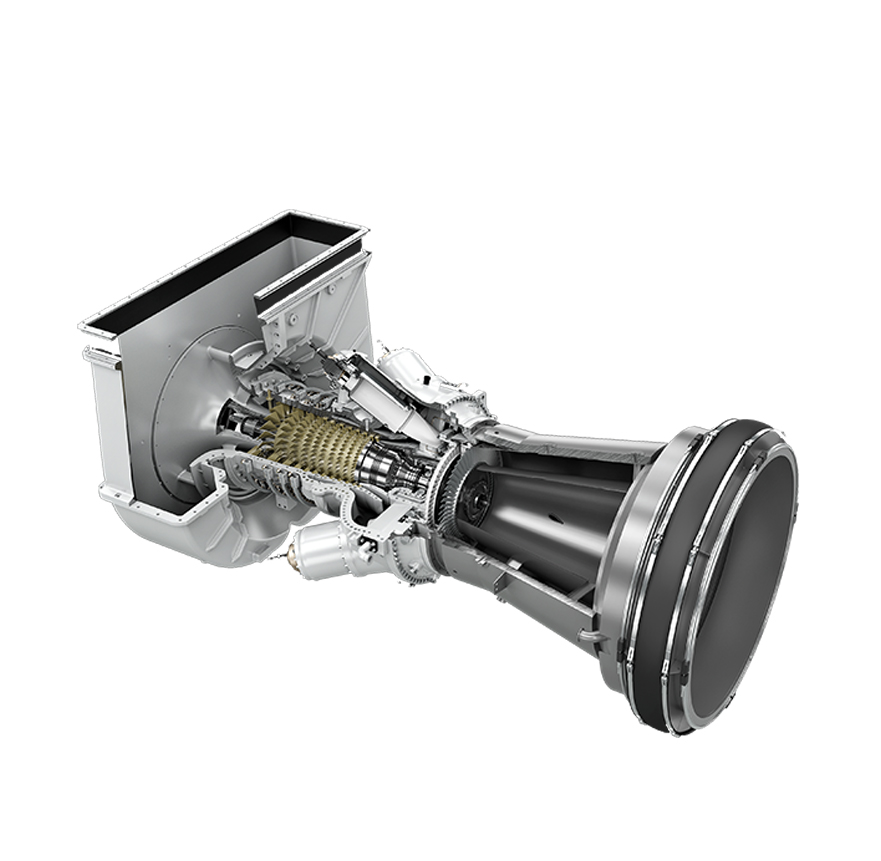

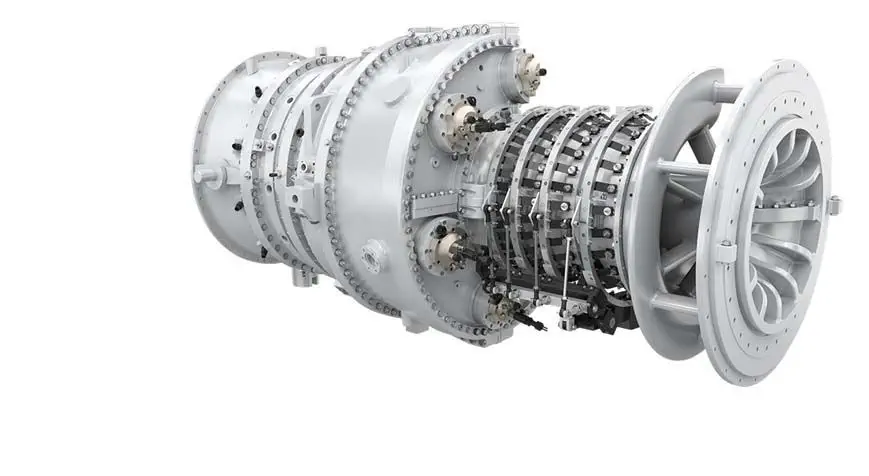

Dual axis engine for mechanical drive and power generation

Simple cycle power generation (ISO) can reach up to

There is extensive flexibility in fuel, operating conditions, maintenance concepts, unit solutions, and ratings.

The development of rotors, blades, and combustion technology has improved efficiency, flexibility, and availability

SGT-400 is a simple and robust dual axis gas turbine suitable for power generation and mechanical drive applications.

This product is suitable for the 10-15 MW power range and can be used in all climate conditions on land and at sea. When SGT-400 made its debut 20 years ago, it had already achieved a technological leap and continued to maintain its leading position in terms of operational and fuel flexibility, low emissions, and overall efficiency. The optimized rotor and blades combined with local support and extended overhaul intervals by 33% ensure high availability and low lifecycle costs. The latest developments, such as the annular design with single-stage combustion, mean that the SGT-400 can burn various fuel components and operate efficiently at all loads. It can meet strict emission standards at loads as low as 30% and has dual fuel capability.

Improve availability with maximum reliability

-The maintenance interval for the hot air path has been extended from 24000 hours to 32000 hours.

-The operation was extended from 48000 hours to 64000 hours before the first major overhaul.

More convenient operation

A large team of cross trained on-site service technicians and engineers, a 24/7 service desk, and remote monitoring make the SGT-400 easier to operate throughout its entire lifecycle.

Yes, we retrofit legacy systems (e.g., GE Frame 5, Siemens V94.2) with modern digital controllers, typically completing hardware integration within 4-8 weeks. Software migration requires additional validation time.

We recommend annual performance testing under ISO 3977-2 standards. Critical applications (e.g., offshore platforms) may require semi-annual tests with emissions compliance checks.

All rad-hard devices (e.g., FPGA, ADC) are QML Class V certified under MIL-PRF-38535 and tested to MIL-STD-883 Method 1019 for SEU tolerance. Full qualification reports are available upon request.

Our ASICs and power management ICs operate across -55°C to +175°C ambient temperatures, with derating curves provided in military temperature range (MTR) datasheets.

Our PMA parts (e.g., actuators, sensors) hold FAA/EASA Form 1 certification and match OEM form/fit/function. Installation requires SB/MB documentation per FAA AC 23.1529.

All NAS/MS fasteners include full DNA traceability: melt source (AMS 2301), heat/lot numbers, and AS9100-compliant MTRs with ultrasonic test reports.

AOG orders ship within 4 hours for stocked items (FAA-PMA, EASA Part 21G). Non-stock critical parts trigger priority manufacturing with 72-hour max turnaround.

Gas Turbine

Gas Turbine

Aircraft parts

Aircraft parts