Proven E-class steam turbine with excellent fuel flexibility

Simple Cycle Power Generation (ISO)

Combined cycle efficiency: 53.3%

Flexible fuel gas turbine suitable for burning crude oil and high viscosity fuels

Reliable, robust, and flexible power generation

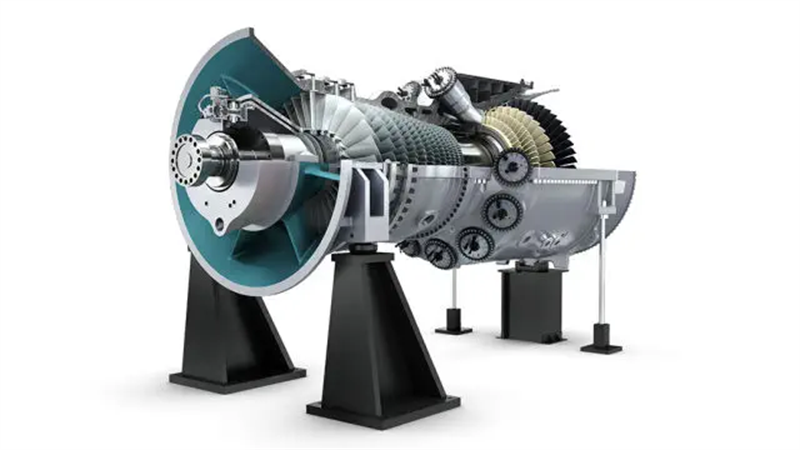

The SGT5-2000E gas turbine is a proven and powerful engine suitable for the 50 Hz market, and can be used for simple or combined cycles, as well as cogeneration.

It is suitable for all load ranges, including peak loads, and provides excellent fuel flexibility: you can use low calorific value gases, gases containing carbon dioxide, hydrogen sulfide, nitrogen, or crude oil, as well as other high viscosity liquid fuels. In addition, even within a partial load range, it can provide low nitrogen oxide emissions.

First class unit reliability

SGT5-2000E unit has rich operational experience, and you will benefit from a reliability of over 99% in unit performance. Its robust turbine design is continuously enhanced through performance upgrades and modifications.

Excellent operational flexibility

With its fast start-up capability, you can achieve full load in about 12 minutes. With its fast load change capability, you can meet the strictest requirements of the power grid for optimal frequency stability.

Superior fuel flexibility

The SGT5-2000E offers dual fuel functionality and excellent fuel flexibility: it can burn low calorific value gases or fuels containing carbon dioxide, hydrogen sulfide, nitrogen, as well as crude oil and other high viscosity liquid fuels. Engines equipped with DLE burners can burn up to 30% by volume of hydrogen (H2).

It provides reliable start-up and conversion between fuels. The automatic transition from primary fuel to auxiliary fuel can be carried out under reduced base load conditions.

Yes, we retrofit legacy systems (e.g., GE Frame 5, Siemens V94.2) with modern digital controllers, typically completing hardware integration within 4-8 weeks. Software migration requires additional validation time.

We recommend annual performance testing under ISO 3977-2 standards. Critical applications (e.g., offshore platforms) may require semi-annual tests with emissions compliance checks.

All rad-hard devices (e.g., FPGA, ADC) are QML Class V certified under MIL-PRF-38535 and tested to MIL-STD-883 Method 1019 for SEU tolerance. Full qualification reports are available upon request.

Our ASICs and power management ICs operate across -55°C to +175°C ambient temperatures, with derating curves provided in military temperature range (MTR) datasheets.

Our PMA parts (e.g., actuators, sensors) hold FAA/EASA Form 1 certification and match OEM form/fit/function. Installation requires SB/MB documentation per FAA AC 23.1529.

All NAS/MS fasteners include full DNA traceability: melt source (AMS 2301), heat/lot numbers, and AS9100-compliant MTRs with ultrasonic test reports.

AOG orders ship within 4 hours for stocked items (FAA-PMA, EASA Part 21G). Non-stock critical parts trigger priority manufacturing with 72-hour max turnaround.

Gas Turbine

Gas Turbine

Aircraft parts

Aircraft parts