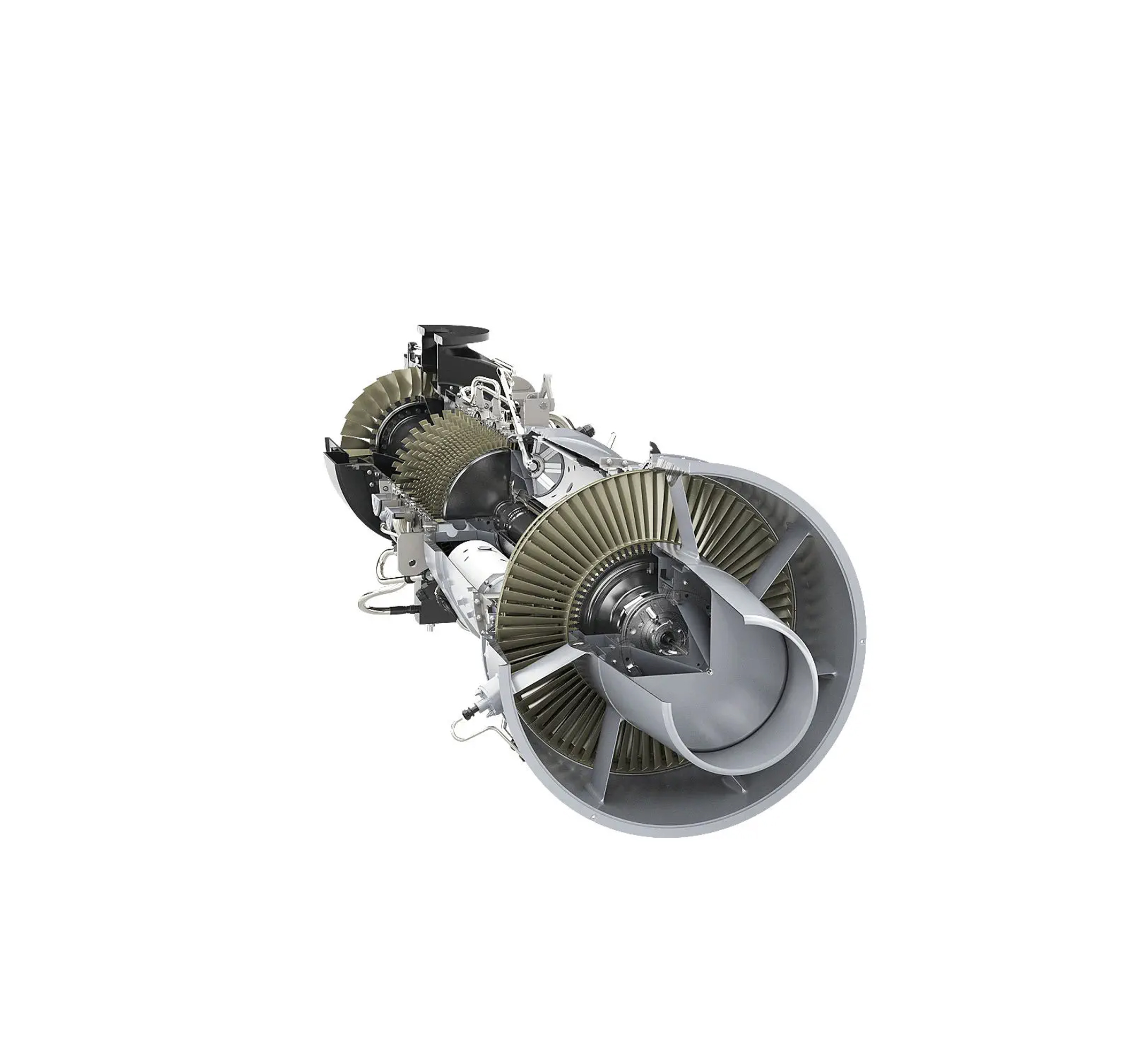

The SGT-100 industrial gas turbine is a proven equipment suitable for all power generation and mechanical transmission applications.

The compact layout, on-site or off-site maintenance capabilities, and inherent reliability make it an ideal gas turbine for the demanding oil and gas industry.

This gas turbine adopts a sturdy and durable industrial design, which can achieve high efficiency and excellent emission performance when using various gases and liquid fuels.

High availability and operational flexibility

With SGT-100, your factory will benefit from world-class availability and maximum operational flexibility. The standard dry low emission (DLE) combustion system can use both liquid and gas fuels, and has lower emissions of nitrogen oxides and carbon monoxide. At the same time, the system can also achieve full load and load shedding through automatic fuel switching without affecting the operation of the steam turbine.

Long established oil and gas tradition

Since 1992, SGT-100 has been used in the oil and gas industry. In power generation and mechanical transmission applications, the SGT-100 has a long operating time, providing reliable operation for oil and gas operators in this demanding industry.

Specially designed for harsh conditions

The SGT-100 can operate under various environmental conditions, ranging from extremely cold and humid to hot and dusty. The packaging design of SGT-100 provides multiple standard options to meet the wide range of environmental conditions.

DLE combustion with low nitrogen oxide emissions

Our SGT-100 gas turbine can be equipped with a dry low emission (DLE) combustion system, which is a modern method that avoids injecting diluents and achieves low nitrogen oxide emissions through mature design.

Yes, we retrofit legacy systems (e.g., GE Frame 5, Siemens V94.2) with modern digital controllers, typically completing hardware integration within 4-8 weeks. Software migration requires additional validation time.

We recommend annual performance testing under ISO 3977-2 standards. Critical applications (e.g., offshore platforms) may require semi-annual tests with emissions compliance checks.

All rad-hard devices (e.g., FPGA, ADC) are QML Class V certified under MIL-PRF-38535 and tested to MIL-STD-883 Method 1019 for SEU tolerance. Full qualification reports are available upon request.

Our ASICs and power management ICs operate across -55°C to +175°C ambient temperatures, with derating curves provided in military temperature range (MTR) datasheets.

Our PMA parts (e.g., actuators, sensors) hold FAA/EASA Form 1 certification and match OEM form/fit/function. Installation requires SB/MB documentation per FAA AC 23.1529.

All NAS/MS fasteners include full DNA traceability: melt source (AMS 2301), heat/lot numbers, and AS9100-compliant MTRs with ultrasonic test reports.

AOG orders ship within 4 hours for stocked items (FAA-PMA, EASA Part 21G). Non-stock critical parts trigger priority manufacturing with 72-hour max turnaround.

Gas Turbine

Gas Turbine

Aircraft parts

Aircraft parts