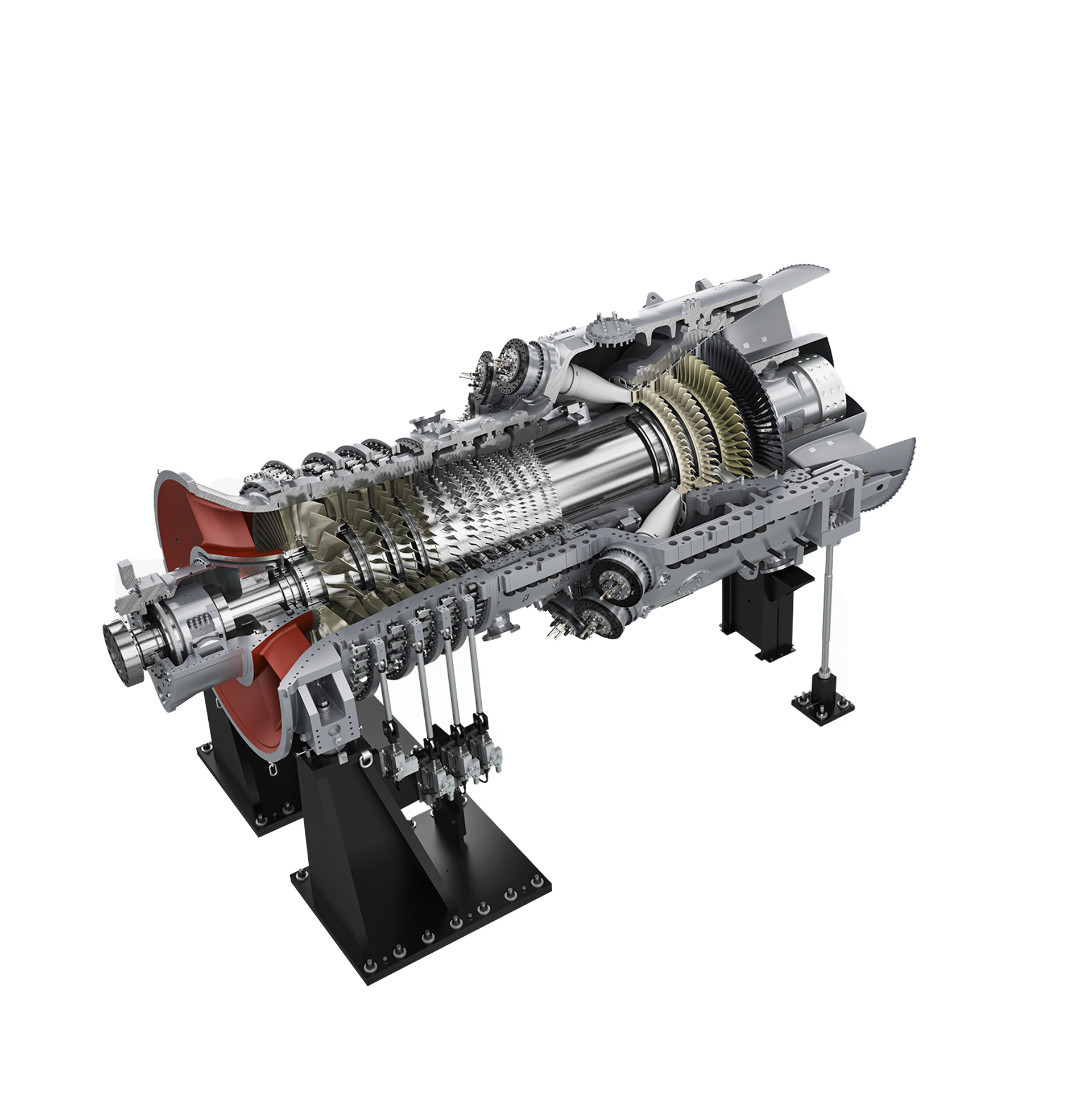

Heavy duty gas turbine (50 Hz)

Trustworthy F-class technology with reliable performance

Single cycle power generation (ISO)

Combined cycle efficiency: 59.7%

Mature and robust design, large installed capacity, and rich operating experience

The SGT5-4000F gas turbine has excellent design, robustness, outstanding performance, and outstanding efficiency. The maintenance downtime is short and easy to maintain, ensuring maximum utilization of the gas turbine.

The internal air cooling design of the gas turbine enables the unit to operate reliably for a long time and has the ability to start quickly. The hydraulic clearance optimization system (HCO) can reduce the performance loss of the unit caused by clearance, improve the efficiency of gas turbines, and minimize the degradation of unit performance during start-up and shutdown.

The proven SGT5-4000F gas turbine has the characteristics of high performance, low power generation cost, long maintenance interval, and easy maintenance. In combined cycle applications, optimized airflow and cooling design can improve the efficiency of gas turbines and achieve economical power generation.

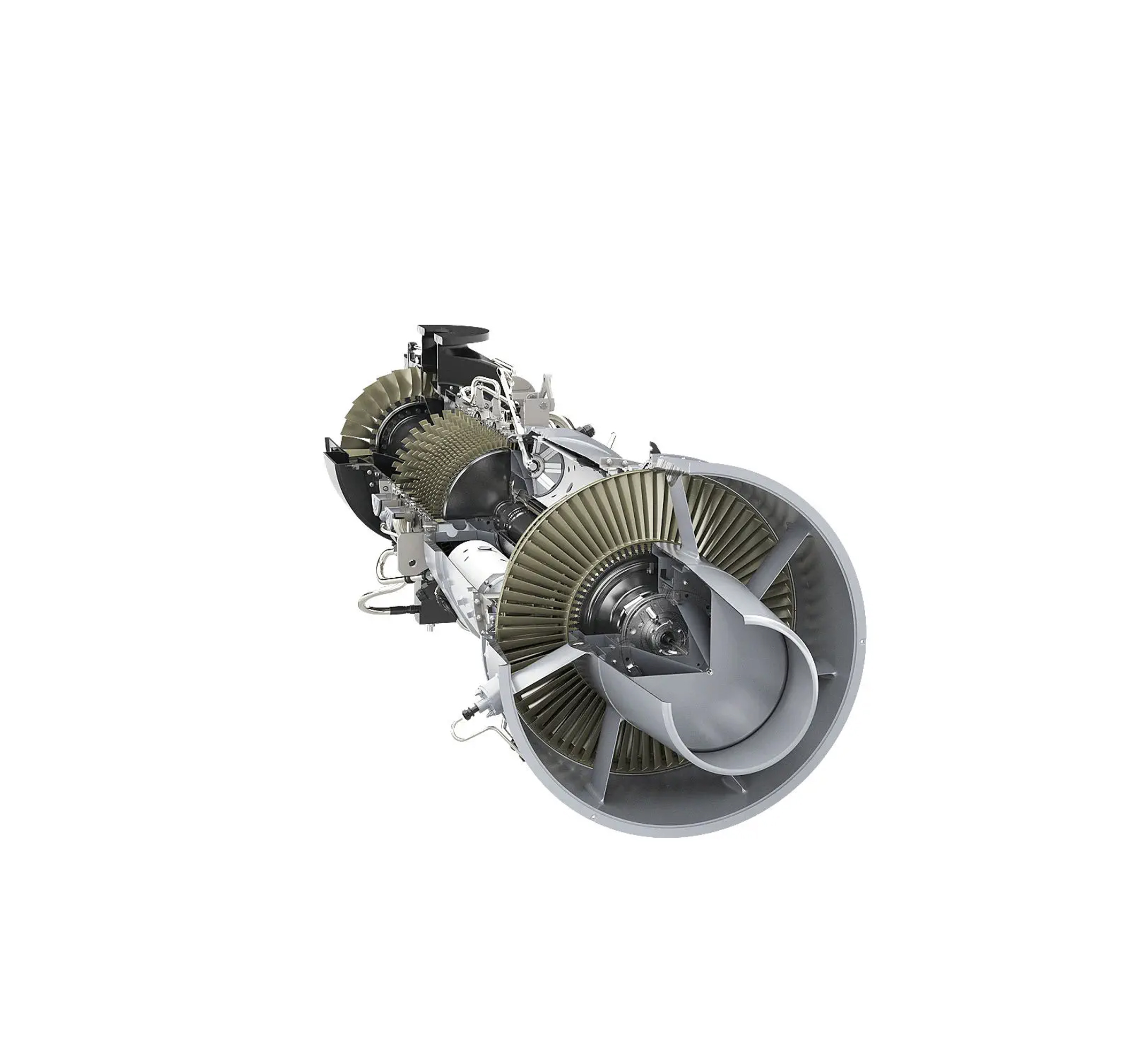

Quick start capability

Due to the use of lightweight rigid rotors with internal cooling air channels, advanced annular burners, and hydraulic clearance optimization systems (HCO) actively controlling clearances, gas turbines have excellent rapid cold and hot start capabilities.

SGT5-4000F reaches the basic load of the combined cycle within 30 minutes of hot start.

Excellent power plant integration

Rich commercial operation experience means that the unit has been proven and verified to be reliable, and can achieve early power generation in a single cycle situation. The project was implemented quickly. Due to the fact that the gas turbine does not require an external rotor air cooler, the equipment integration requirements are further simplified.

Yes, we retrofit legacy systems (e.g., GE Frame 5, Siemens V94.2) with modern digital controllers, typically completing hardware integration within 4-8 weeks. Software migration requires additional validation time.

We recommend annual performance testing under ISO 3977-2 standards. Critical applications (e.g., offshore platforms) may require semi-annual tests with emissions compliance checks.

All rad-hard devices (e.g., FPGA, ADC) are QML Class V certified under MIL-PRF-38535 and tested to MIL-STD-883 Method 1019 for SEU tolerance. Full qualification reports are available upon request.

Our ASICs and power management ICs operate across -55°C to +175°C ambient temperatures, with derating curves provided in military temperature range (MTR) datasheets.

Our PMA parts (e.g., actuators, sensors) hold FAA/EASA Form 1 certification and match OEM form/fit/function. Installation requires SB/MB documentation per FAA AC 23.1529.

All NAS/MS fasteners include full DNA traceability: melt source (AMS 2301), heat/lot numbers, and AS9100-compliant MTRs with ultrasonic test reports.

AOG orders ship within 4 hours for stocked items (FAA-PMA, EASA Part 21G). Non-stock critical parts trigger priority manufacturing with 72-hour max turnaround.

Gas Turbine

Gas Turbine

Aircraft parts

Aircraft parts