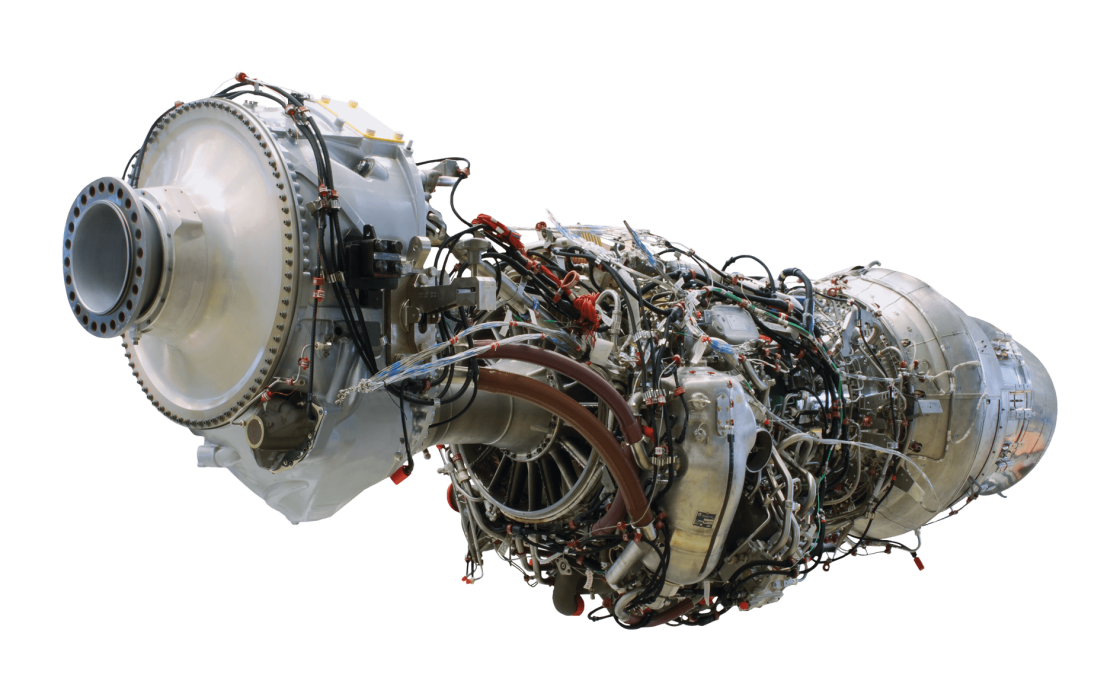

Combining a full authority digital engine and propeller control in a single compact unit, the FADEPC GE Catalyst is a first for the industry. It reduces pilot workload while providing greater levels of control and responsiveness.

Automatic optimization of fuel flow, prop pitch and speed

Improvement of pilot’s control and responsiveness

Optimum efficiency even in harsh weather conditions

Compact, the FADEPC GE CATALYST Digital Engine and Propeller Control unit automatically optimizes fuel flow, prop pitch and speed, for maximum efficiency in all conditions. Developed by FADEC Alliance, the FADEPC equips the GE Catalyst engine powering the future Cessna Denali turboprop.

The world leader in full authority digital engine controls for civil aviation via FADEC International, a joint venture with BAE Systems, Safran Electronics & Defense relies on its 35+ years of expertise in design, production and support of FADEC systems. Our FADECs ensure a high level of safety and performance for optimum engine operations. FADEC Alliance is a joint venture between FADEC International and GE.

Yes, we retrofit legacy systems (e.g., GE Frame 5, Siemens V94.2) with modern digital controllers, typically completing hardware integration within 4-8 weeks. Software migration requires additional validation time.

We recommend annual performance testing under ISO 3977-2 standards. Critical applications (e.g., offshore platforms) may require semi-annual tests with emissions compliance checks.

All rad-hard devices (e.g., FPGA, ADC) are QML Class V certified under MIL-PRF-38535 and tested to MIL-STD-883 Method 1019 for SEU tolerance. Full qualification reports are available upon request.

Our ASICs and power management ICs operate across -55°C to +175°C ambient temperatures, with derating curves provided in military temperature range (MTR) datasheets.

Our PMA parts (e.g., actuators, sensors) hold FAA/EASA Form 1 certification and match OEM form/fit/function. Installation requires SB/MB documentation per FAA AC 23.1529.

All NAS/MS fasteners include full DNA traceability: melt source (AMS 2301), heat/lot numbers, and AS9100-compliant MTRs with ultrasonic test reports.

AOG orders ship within 4 hours for stocked items (FAA-PMA, EASA Part 21G). Non-stock critical parts trigger priority manufacturing with 72-hour max turnaround.

Gas Turbine

Gas Turbine

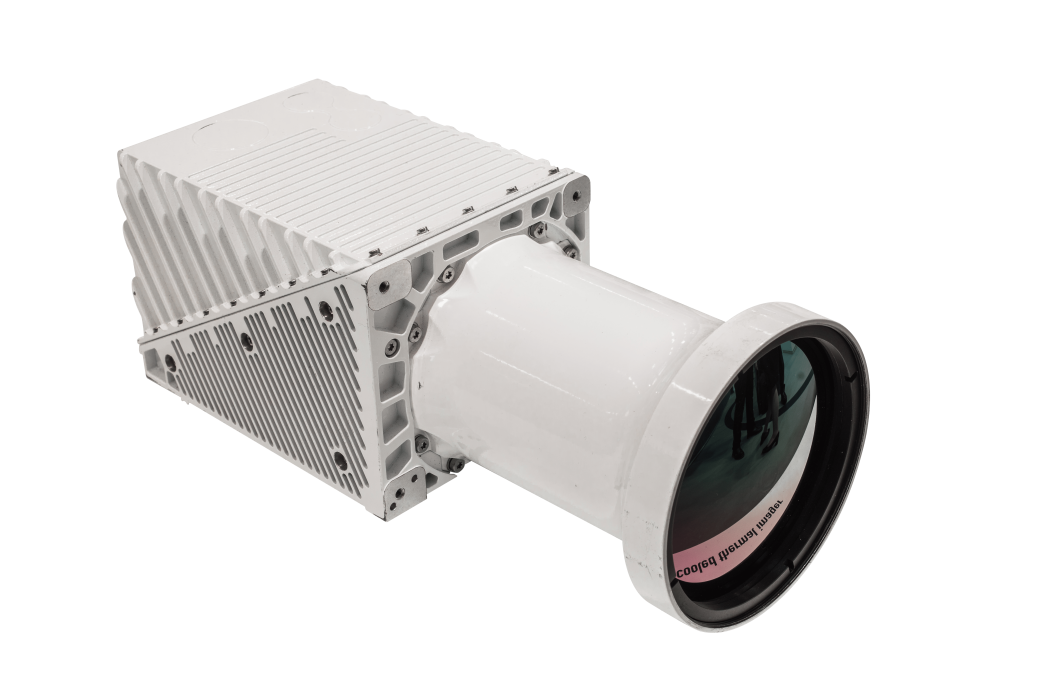

Aircraft parts

Aircraft parts