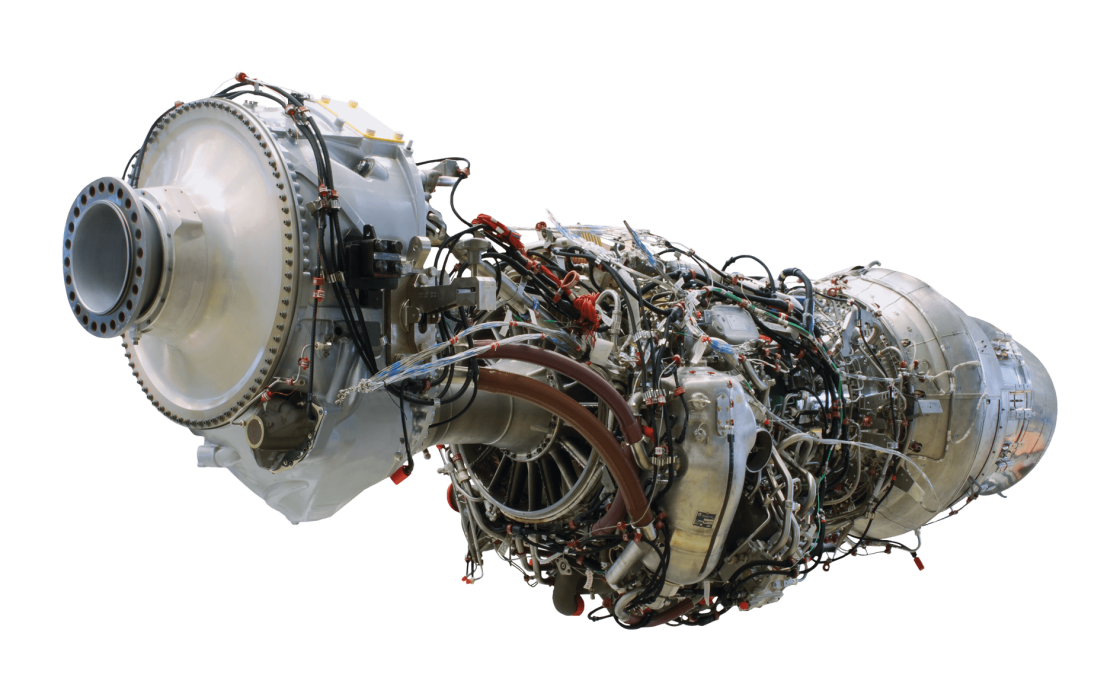

Developed, produced and marketed by Europrop International, the TP400-D6 powers the Airbus A400M new-generation military transport aircraft, designed for tactical and strategic airlift missions, as well as in-flight refueling.

Its dual civil/military certification means it can quickly reach theaters of operations.

The highest standards of dispatch reliability, operational availability and versatility.

Low fuel consumption, which gives the A400M extended range.

Most powerful turboprop in the West

11,600shp

The TP400 is developed and produced by Europrop International (EPI), a European consortium between Safran Aircraft Engines, ITP Aero, MTU Aero Engines and Rolls-Royce. Safran Aircraft Engines is the lead partner, with a 32% workshare, and is responsible for the combustor, high-pressure turbine, FADEC engine control system and accessory gearbox.

As part of Europrop International, Safran Aircraft Engines is in charge of maintenance for components under its responsibility, along with engine removal and module disassembly for certain customers. The company supplies parts and provides online technical assistance and logistics support. It also dispatches special tech reps to air force bases.

Key figures

The A400M’s payload capacity, made possible by the TP400

40t

total flight hours

200,000h

Safran Aircraft Engines’ workshare within Europrop International

32%

Yes, we retrofit legacy systems (e.g., GE Frame 5, Siemens V94.2) with modern digital controllers, typically completing hardware integration within 4-8 weeks. Software migration requires additional validation time.

We recommend annual performance testing under ISO 3977-2 standards. Critical applications (e.g., offshore platforms) may require semi-annual tests with emissions compliance checks.

All rad-hard devices (e.g., FPGA, ADC) are QML Class V certified under MIL-PRF-38535 and tested to MIL-STD-883 Method 1019 for SEU tolerance. Full qualification reports are available upon request.

Our ASICs and power management ICs operate across -55°C to +175°C ambient temperatures, with derating curves provided in military temperature range (MTR) datasheets.

Our PMA parts (e.g., actuators, sensors) hold FAA/EASA Form 1 certification and match OEM form/fit/function. Installation requires SB/MB documentation per FAA AC 23.1529.

All NAS/MS fasteners include full DNA traceability: melt source (AMS 2301), heat/lot numbers, and AS9100-compliant MTRs with ultrasonic test reports.

AOG orders ship within 4 hours for stocked items (FAA-PMA, EASA Part 21G). Non-stock critical parts trigger priority manufacturing with 72-hour max turnaround.

Gas Turbine

Gas Turbine

Aircraft parts

Aircraft parts