ClearVision is a complete Enhanced Flight Vision System (EFVS) with SkyVis helmet-mounted display (HMD) for intuitive out-the-window helicopter operations. ClearVision is the market's proven solution, selected by leading helicopter platform manufacturers and corporate transport and mission operators around the world.

ClearVision is a complete Enhanced Flight Vision System (EFVS) solution providing head-up symbology combined with Enhanced Vision (EVS) and Synthetic Vision (SVS). It features an unlimited field of view, with the brightest and highest resolution Helmet-Mounted Display (HMD) and Head-Wearable Display (HWD) solutions for rotorcraft in the market. ClearVision's unique pilot-friendly split screen display allows the user to change between the two background imagery areas for optimal control. With the ClearVision system, overcome extreme weather conditions and low visibility situations – day, night, and with Night Vision Goggles (NVG). Intuitive head-up, eyes-out flying is now possible.

As a Level A certified solution, the ClearVision suite is the market’s proven solution, selected by leading helicopter platform manufacturers, and corporate transport and mission operators around the world.

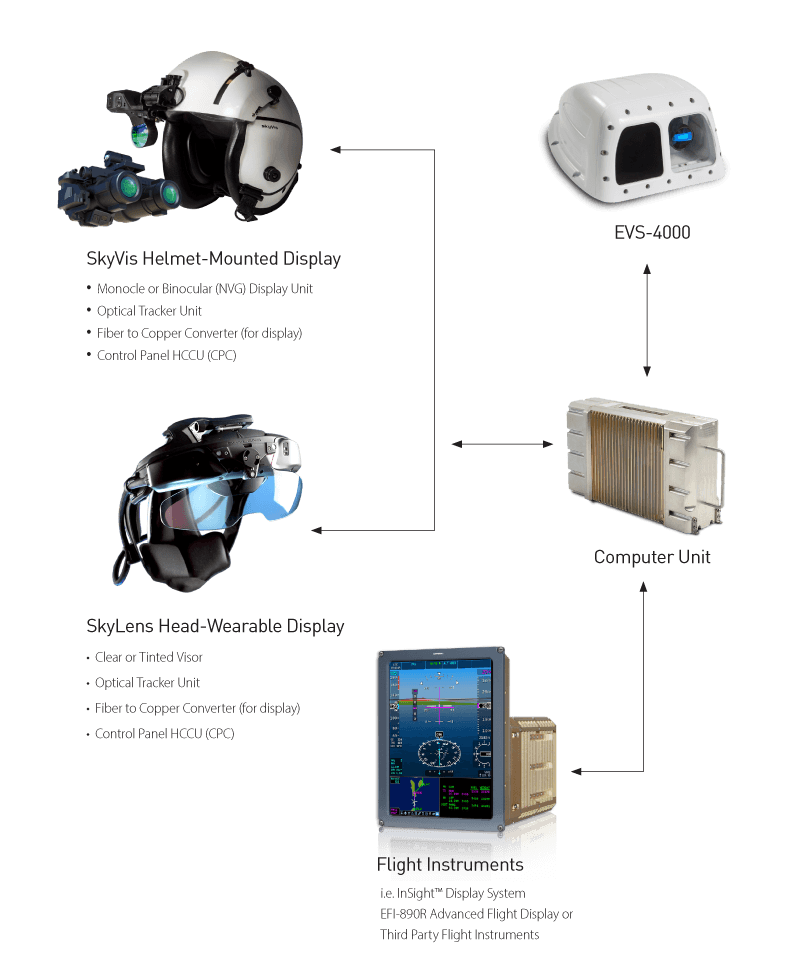

The SkyVis Helmet-Mounted Display (HMD) offers the latest in commercially certifiable Line-Of-Sight (LOS) technology. It includes day, night and Night Vision Goggle (NVG) capabilities with enhanced safety for ‘round-the-clock’ mission support for SAR, EMS, parapublic, offshore, and day-to-day utility operators. The system enables “eyes out” operation during all phases of flight and an unparalleled view of the outside world with aircraft, mission, terrain, flight, obstacle, and navigation data.

SkyVis uses a helmet-mounted, monochrome, monocular display, which augments the operator’s vision with HUD symbology, as well as optional SVS, EVS-4000, or CVS imagery. The display module does not require helmet modification and mounts directly to existing NVG mounting hardware. The SkyVis NVG option also mounts to the helmet’s existing mounting hardware and provides NVG compatible display symbology.

SkyVis and SkyVis NVG displays are adjustable to accommodate multiple Inter Pupil Distances (IPD) and are compatible with prescription eyeglasses.

SkyLens is a revolutionary Head-Wearable Display (HWD), ideal for anyone seeking an easy-to-install, retrofittable, and flexible HUD solution. High-resolution symbology, SVS, and EVS are presented on a high-transparency visor. The easy-to-wear device provides superior see-through transmission for corporate transport operations in all weather conditions, day and night, and unlimited field of view. The wide-viewing angle allows the pilot to look 180 degrees to the left or right to view panoramic SVS imagery for unprecedented situational awareness. In addition, the pilot is not constrained to sitting in a specific position as is necessary with a traditional HUD.

SkyLens uses a head-harnessed, monochrome, visor display, augmenting the operator’s vision with HUD symbology, as well as optional SVS, EVS-4000, or CVS imagery. SkyLens’ design allows operators to wear prescription eyeglasses and to use a standard aviation headset.

The EVS-4000 ClearVision Enhanced Vision System provides a superior visual solution augmented with real-time synthetic information, designed to expand the safety and operational capabilities of your HMD / HWD system. With its advanced real-time visual processing, EVS-4000 merges the input of high definition visual cameras, with sophisticated fusion algorithms and a range of bands including visible light and Near Infrared (NIR). The result is a superior visual solution, expanding your situational awareness in any weather condition like never before.

EVS-4000 is designed to increase platform efficiency and safety, with the latest visual-processing technology, meeting all FAA/EASA/ICAO/CAAC EVS or EFVS civil certification requirements.

Yes, we retrofit legacy systems (e.g., GE Frame 5, Siemens V94.2) with modern digital controllers, typically completing hardware integration within 4-8 weeks. Software migration requires additional validation time.

We recommend annual performance testing under ISO 3977-2 standards. Critical applications (e.g., offshore platforms) may require semi-annual tests with emissions compliance checks.

All rad-hard devices (e.g., FPGA, ADC) are QML Class V certified under MIL-PRF-38535 and tested to MIL-STD-883 Method 1019 for SEU tolerance. Full qualification reports are available upon request.

Our ASICs and power management ICs operate across -55°C to +175°C ambient temperatures, with derating curves provided in military temperature range (MTR) datasheets.

Our PMA parts (e.g., actuators, sensors) hold FAA/EASA Form 1 certification and match OEM form/fit/function. Installation requires SB/MB documentation per FAA AC 23.1529.

All NAS/MS fasteners include full DNA traceability: melt source (AMS 2301), heat/lot numbers, and AS9100-compliant MTRs with ultrasonic test reports.

AOG orders ship within 4 hours for stocked items (FAA-PMA, EASA Part 21G). Non-stock critical parts trigger priority manufacturing with 72-hour max turnaround.

Gas Turbine

Gas Turbine

Aircraft parts

Aircraft parts