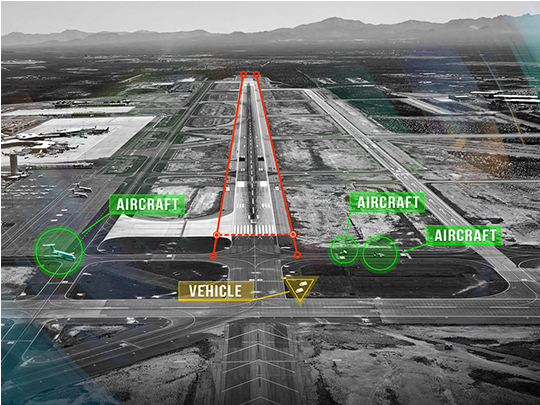

Turning video into Situation Intelligence. Aperture is a suite of capabilities that will set a new standard in real-time sensor fusion, AI-powered augmented reality, providing unparalleled situational awareness to flight crews and mission specialists, while increasing aircraft safety. Initially oriented towards multi-sensor video management, this family of products can process a variety of video and sensor inputs to deliver real-time content analysis, such as visual positioning, obstacle detection, taxi guidance, and traffic awareness.

The initial release of Aperture can process up to 8 video inputs and support up to 4 video outputs with near zero latency, wrapped in the highest design criticality attainable in aviation - Design Assurance Level A.

Universal Avionics, a well-established leader in Head-Down, Head-Up and Head Wearable Displays, with features such as Combined Vision Systems (CVS) – a mix of Enhanced Vision (EVS) and Synthetic Vision Systems (SVS), brings to market Aperture.

Stitch, blend, enhance contrast, and more. This is the power of Aperture. Need several inputs presented on the same display? Need color correction and brightness enhancement on an output channel? No problem. As an example, stitching and blending several sensor inputs located around an aircraft could result in a composite image with a large Field Of Regard (FOR) – a perfect complement to Universal Avionics’ SkyLens™ HWD. By digitally panning across this composite image, a given Field Of View (FOV) can be presented to flight crews wearing the display, vastly improving their situational awareness and enhancing safety. An invaluable capability in high workload situations such as ground operations during limited visibility conditions.

Universal Avionics’ dedicated team of engineers and Artificial Intelligence specialists are forging a path towards the delivery of augmented reality. In advanced development, the hardware platform will deliver cutting-edge neural networking and significant mass storage capabilities. This platform is the foundation to host Universal’s advanced proprietary algorithms and bring to reality, in real time, automatic object detection, classification and notification, semantic segmentation and more. Currently undergoing trials, these algorithms will enable the detection and classification of nearby power lines, traffic on and around an active runway and beyond. The platform will augment this information with other data from on-board sensors and other avionics systems (mission computers, FMS, etc.), and where appropriate provide to the flight crew augmented awareness and guidance throughout the flight.

Yes, we retrofit legacy systems (e.g., GE Frame 5, Siemens V94.2) with modern digital controllers, typically completing hardware integration within 4-8 weeks. Software migration requires additional validation time.

We recommend annual performance testing under ISO 3977-2 standards. Critical applications (e.g., offshore platforms) may require semi-annual tests with emissions compliance checks.

All rad-hard devices (e.g., FPGA, ADC) are QML Class V certified under MIL-PRF-38535 and tested to MIL-STD-883 Method 1019 for SEU tolerance. Full qualification reports are available upon request.

Our ASICs and power management ICs operate across -55°C to +175°C ambient temperatures, with derating curves provided in military temperature range (MTR) datasheets.

Our PMA parts (e.g., actuators, sensors) hold FAA/EASA Form 1 certification and match OEM form/fit/function. Installation requires SB/MB documentation per FAA AC 23.1529.

All NAS/MS fasteners include full DNA traceability: melt source (AMS 2301), heat/lot numbers, and AS9100-compliant MTRs with ultrasonic test reports.

AOG orders ship within 4 hours for stocked items (FAA-PMA, EASA Part 21G). Non-stock critical parts trigger priority manufacturing with 72-hour max turnaround.

Gas Turbine

Gas Turbine

Aircraft parts

Aircraft parts