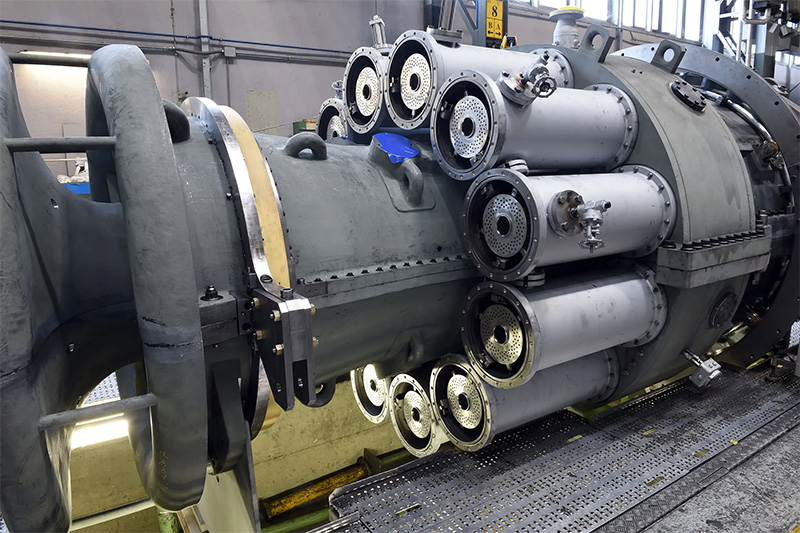

Single-shaft gas turbine built on a solid foundation with best-in-class availability and reliability Benefits Excellent availability and reliability as a prime mover; designed for long life Enhanced fuel flexibility with no impact on combustor’s operability or integrity Compact package design for easier maintenance; single-lift basement for engine and auxiliaries Features 17-stage axial compressor adopted on former N, P, and PA models Multi-can DLN1 combustion system with dual-fuel capability for STD/LHE Single-shaft turbine hot-end drive architecture; two-stage turbine with uncooled buckets Applications Refinery, petrochemical, and fertilizer Industrial, and combined heat and power At ISO conditions with natural gas fuel, ambient temperature 15°C, no inlet exhaust losses, sea level, 60% relative humidity. Assuming average efficiency of gearbox and generator. Package dimensions include driven equipment. Fuel flexibility A single-chamber, full-scale test campaign was conducted on DLN1 hardware to assess the combustor’s capability to operate with increasing C2+ levels in the fuel gas. Standard hardware currently installed on Frame 5/1PA DLN1 units are suitable to burn fuel gases with up to 40% C2+ (C2 to C4 alkanes) with no issues for the combustor’s operability or integrity. Fuel composition The Frame 5/1PA DLN1 can burn heavy hydrocarbons (25% max ethane content or 20% max propane), inerts (25% max CO2 or 25% max N2), hydrogen up to 20%, liquid fuel (distillate #2 at 42 ppm wet). Performance enhancement Maintenance plan enhancement (35,000/70,000 hours) can be provided as an option on the standard/LHE configuration.

Yes, we retrofit legacy systems (e.g., GE Frame 5, Siemens V94.2) with modern digital controllers, typically completing hardware integration within 4-8 weeks. Software migration requires additional validation time.

We recommend annual performance testing under ISO 3977-2 standards. Critical applications (e.g., offshore platforms) may require semi-annual tests with emissions compliance checks.

All rad-hard devices (e.g., FPGA, ADC) are QML Class V certified under MIL-PRF-38535 and tested to MIL-STD-883 Method 1019 for SEU tolerance. Full qualification reports are available upon request.

Our ASICs and power management ICs operate across -55°C to +175°C ambient temperatures, with derating curves provided in military temperature range (MTR) datasheets.

Our PMA parts (e.g., actuators, sensors) hold FAA/EASA Form 1 certification and match OEM form/fit/function. Installation requires SB/MB documentation per FAA AC 23.1529.

All NAS/MS fasteners include full DNA traceability: melt source (AMS 2301), heat/lot numbers, and AS9100-compliant MTRs with ultrasonic test reports.

AOG orders ship within 4 hours for stocked items (FAA-PMA, EASA Part 21G). Non-stock critical parts trigger priority manufacturing with 72-hour max turnaround.

Gas Turbine

Gas Turbine

Aircraft parts

Aircraft parts