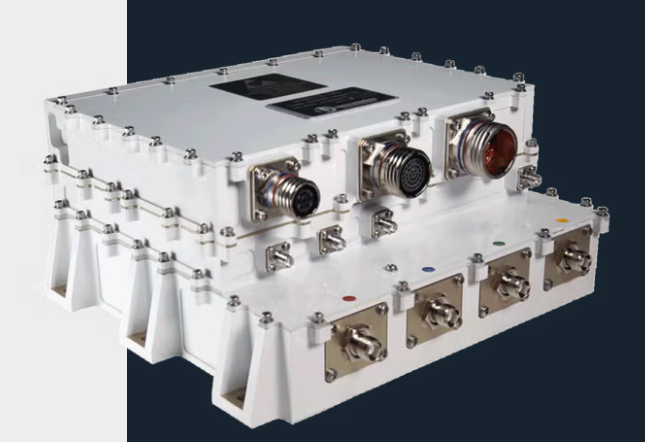

Network Sentry is a powerful, compact computer that hosts Site Management Services as part of L3Harris’ total Site Management System.

It provides a full array of digital communications capabilities for fast, accurate, and efficient relay of critical information. As part of an L3Harris P25 network, Network Sentry plays a crucial role in meeting the communication requirements of public safety, public service, and first responders.

The Network Sentry monitors the site call processing local areanetwork (LAN) for call activity and fault messages. The Network Sentry ensures that data such as user, group, and channel configurations is reliably transferred to configured site devices.

Management of resources is easier and more efficient with the Network Sentry because it was designed to take full advantage of the sophisticated capabilities of an L3Harris P25IP network. The Network Sentry provides a detailed snapshot of the entire system, showing exact locations of problems and potential problems. Its fault monitoring services take input from the site call processing LAN, RF Power, Digital Input/Output (I/O), and Channel Test services and present alarms to external management systems via Simple Network Management Protocol (SNMP) to determine the location of the potential problems and identify in detail the severity, status, and reason for the most recent failure. This increases operator awareness, improves response time for maintaining vital communication links, and decreases repair time and system downtime.

The Network Sentry allows users to create a flexible work environment tailored to help improve efficiency and productivity. It is equipped with an array of digital Input/Outputs (I/Os) which can be used to control relay logic devices. These digital I/Os can also be configured by the user to indicate faults in devices such as tower beacons, doors and temperature alarms that require remote controlling and monitoring. This information allows users to make quick, informed decisions to meet their needs and to adapt as those needs change.

Yes, we retrofit legacy systems (e.g., GE Frame 5, Siemens V94.2) with modern digital controllers, typically completing hardware integration within 4-8 weeks. Software migration requires additional validation time.

We recommend annual performance testing under ISO 3977-2 standards. Critical applications (e.g., offshore platforms) may require semi-annual tests with emissions compliance checks.

All rad-hard devices (e.g., FPGA, ADC) are QML Class V certified under MIL-PRF-38535 and tested to MIL-STD-883 Method 1019 for SEU tolerance. Full qualification reports are available upon request.

Our ASICs and power management ICs operate across -55°C to +175°C ambient temperatures, with derating curves provided in military temperature range (MTR) datasheets.

Our PMA parts (e.g., actuators, sensors) hold FAA/EASA Form 1 certification and match OEM form/fit/function. Installation requires SB/MB documentation per FAA AC 23.1529.

All NAS/MS fasteners include full DNA traceability: melt source (AMS 2301), heat/lot numbers, and AS9100-compliant MTRs with ultrasonic test reports.

AOG orders ship within 4 hours for stocked items (FAA-PMA, EASA Part 21G). Non-stock critical parts trigger priority manufacturing with 72-hour max turnaround.

Gas Turbine

Gas Turbine

Aircraft parts

Aircraft parts