Fault-tolerant autonomous flight termination with embedded M-Code GPS

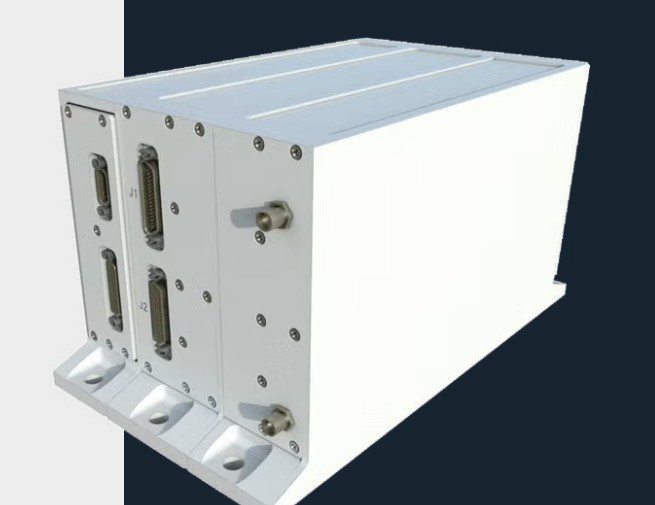

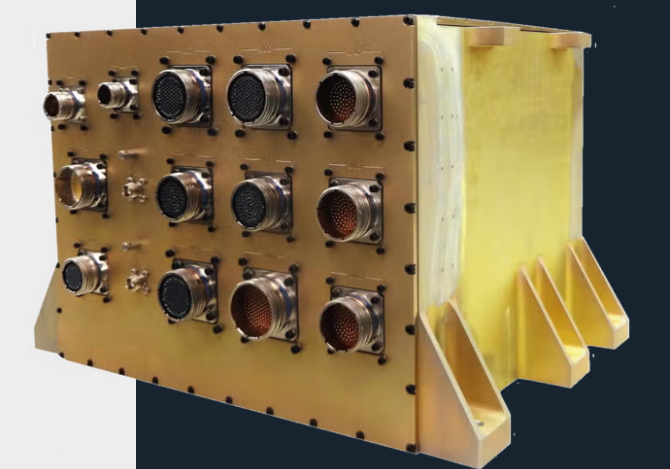

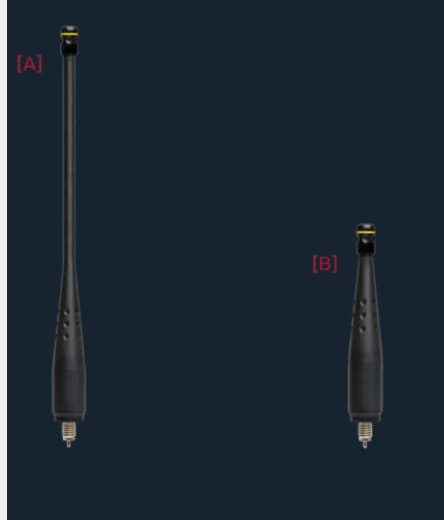

The L3Harris AFTU is a configurable, fault-tolerant autonomous flight termination unit and the core of L3Harris’ autonomous flight safety system. The only RCC-319 -certified flight termination unit with M-code GPS compatibility, the AFTU is poised to support present and future launch requirements into 2030 and beyond. The AFTU integrates multiple functions into a single unit to keep the system affordable, compact and reliable:

Built on a 50-year history of flight termination experience, the AFTU leverages heritage circuit designs on all functions listed above, with proven performance on Atlas V, Delta IV, Space Launch System, Space Shuttle, ISS and many other missions.

The AFTU is single-fault tolerant, with redundancy in the master safe/arm, local arm, liftoff indicators, initiation circuits and all flight-critical FPGAs. Local and remote cross strap heartbeat monitors ensure safe utilization of redundant hardware configurations. The embedded power changeover switch can disable the AFTU once out of the range safety boundary for further fault protection.

L3Harris has been providing rock-solid flight termination hardware for over 50 years with zero operational failures across all product lines. The AFTU can be trusted to perform flawlessly on every mission

Yes, we retrofit legacy systems (e.g., GE Frame 5, Siemens V94.2) with modern digital controllers, typically completing hardware integration within 4-8 weeks. Software migration requires additional validation time.

We recommend annual performance testing under ISO 3977-2 standards. Critical applications (e.g., offshore platforms) may require semi-annual tests with emissions compliance checks.

All rad-hard devices (e.g., FPGA, ADC) are QML Class V certified under MIL-PRF-38535 and tested to MIL-STD-883 Method 1019 for SEU tolerance. Full qualification reports are available upon request.

Our ASICs and power management ICs operate across -55°C to +175°C ambient temperatures, with derating curves provided in military temperature range (MTR) datasheets.

Our PMA parts (e.g., actuators, sensors) hold FAA/EASA Form 1 certification and match OEM form/fit/function. Installation requires SB/MB documentation per FAA AC 23.1529.

All NAS/MS fasteners include full DNA traceability: melt source (AMS 2301), heat/lot numbers, and AS9100-compliant MTRs with ultrasonic test reports.

AOG orders ship within 4 hours for stocked items (FAA-PMA, EASA Part 21G). Non-stock critical parts trigger priority manufacturing with 72-hour max turnaround.

Gas Turbine

Gas Turbine

Aircraft parts

Aircraft parts