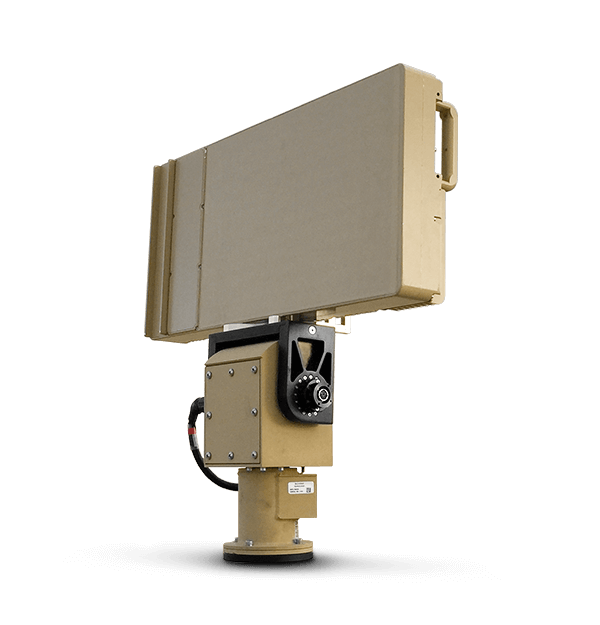

The TacFLIR® 380-HLD combines laser target designation with digital, high-definition EO-IR imaging for land vehicle applications. As a targeting system, TacFLIR 380-HLD is unmatched in its ability to optimize performance of precision-guided munitions from land vehicle environments. Payload includes a MWIR camera with a native 1280x720 resolution, HD CCD cameras, SWIR camera, and high powered laser designator (LD).

Single LRU System

The only all-digital, HD system in a single LRU for ease of installation and integration. Reliably operates in long-term, remote missions sets without the need for external cooling.

Up to 7 Simultaneous Payloads

Options include 1280x720 MWIR resolution, HD CCD camera, HD SWIR, laser range finder, illuminator and laser pointer.

Long-Range Capability

High-magnification optics and HD cameras allow operators to observe from a safe standoff distance without being detected or compromising situational awareness.

Yes, we retrofit legacy systems (e.g., GE Frame 5, Siemens V94.2) with modern digital controllers, typically completing hardware integration within 4-8 weeks. Software migration requires additional validation time.

We recommend annual performance testing under ISO 3977-2 standards. Critical applications (e.g., offshore platforms) may require semi-annual tests with emissions compliance checks.

All rad-hard devices (e.g., FPGA, ADC) are QML Class V certified under MIL-PRF-38535 and tested to MIL-STD-883 Method 1019 for SEU tolerance. Full qualification reports are available upon request.

Our ASICs and power management ICs operate across -55°C to +175°C ambient temperatures, with derating curves provided in military temperature range (MTR) datasheets.

Our PMA parts (e.g., actuators, sensors) hold FAA/EASA Form 1 certification and match OEM form/fit/function. Installation requires SB/MB documentation per FAA AC 23.1529.

All NAS/MS fasteners include full DNA traceability: melt source (AMS 2301), heat/lot numbers, and AS9100-compliant MTRs with ultrasonic test reports.

AOG orders ship within 4 hours for stocked items (FAA-PMA, EASA Part 21G). Non-stock critical parts trigger priority manufacturing with 72-hour max turnaround.

Gas Turbine

Gas Turbine

Aircraft parts

Aircraft parts