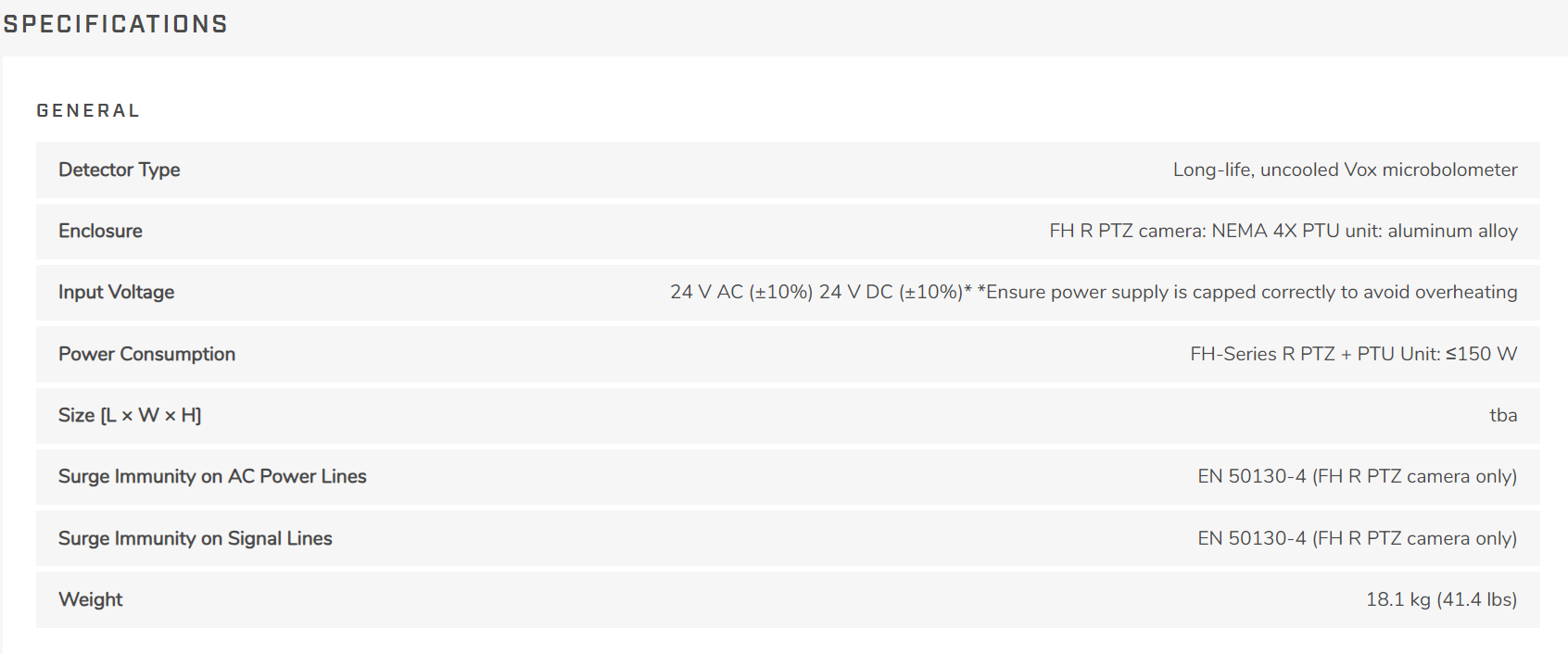

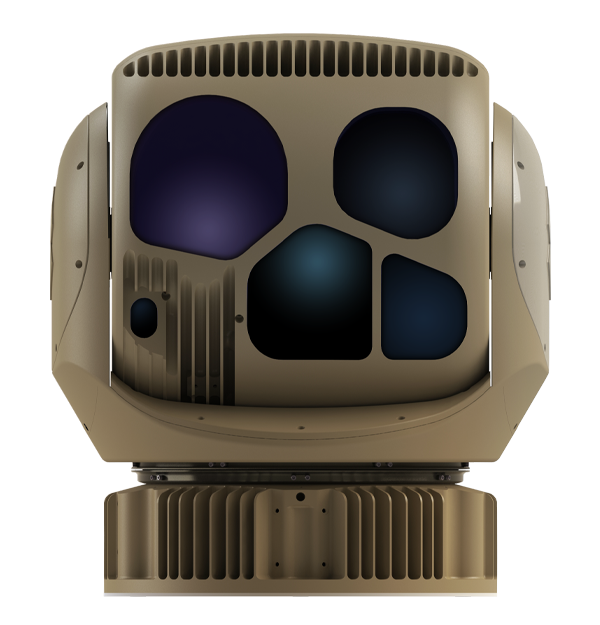

The FH-Series R PTZ is a ruggedized, fixed Pan-Tilt Zoom IP visible plus thermal radiometric camera for fire detection and security applications. This multi-spectral camera integrates industry-leading thermal imaging with 1080p visible imaging to provide rapid visual verification of smoke and hot spots and for detecting fires early in outdoor areas. The onboard radiometry in the camera, combined with Pan-Tilt-Zoom functionality, enables continuous wide area coverage and round the clock monitoring against potential fires. When a hot spot or surface temperature change is detected, the contactless temperature measurement is sent to the operator through a connected Video Management System (VMS) for instantaneous assessment and deployment of response tactics. Custom scheduling provides security personnel the flexibility to enable and disable alarms depending on business hours and seasonality.

Protect large and small areas from fires

Integrates a high-resolution radiometric <35 mK NETD thermal sensor with a 1080p visual, 30x zoom camera for hot spot detection and visual verification.

Detect hot spots early

Measures surface temperatures and processes temperature differences in real time.

Highly-customizable measurement and alarms

Onboard radiometry delivers minimum, maximum, average and differential temperature measurement in user-defined spots, box and polygon shaped areas.

Yes, we retrofit legacy systems (e.g., GE Frame 5, Siemens V94.2) with modern digital controllers, typically completing hardware integration within 4-8 weeks. Software migration requires additional validation time.

We recommend annual performance testing under ISO 3977-2 standards. Critical applications (e.g., offshore platforms) may require semi-annual tests with emissions compliance checks.

All rad-hard devices (e.g., FPGA, ADC) are QML Class V certified under MIL-PRF-38535 and tested to MIL-STD-883 Method 1019 for SEU tolerance. Full qualification reports are available upon request.

Our ASICs and power management ICs operate across -55°C to +175°C ambient temperatures, with derating curves provided in military temperature range (MTR) datasheets.

Our PMA parts (e.g., actuators, sensors) hold FAA/EASA Form 1 certification and match OEM form/fit/function. Installation requires SB/MB documentation per FAA AC 23.1529.

All NAS/MS fasteners include full DNA traceability: melt source (AMS 2301), heat/lot numbers, and AS9100-compliant MTRs with ultrasonic test reports.

AOG orders ship within 4 hours for stocked items (FAA-PMA, EASA Part 21G). Non-stock critical parts trigger priority manufacturing with 72-hour max turnaround.

Gas Turbine

Gas Turbine

Aircraft parts

Aircraft parts