Industry-leading industrial power supplies at the forefront of power technology. SynQor's industrial COTS modules are powering some of the most sophisticated system solutions in the manufacturing sector including applications such as RF amplifiers, industrial servers, commercial radar, GPS, and much more.

SynQor’s ruggedized isolated InQor® DC-DC converters and filters are designed for a wide range of industrial applications including those required to withstand harsh environments: railway and transportation systems, industrial motion control, information displays, factory automation and power generation systems. SynQor converters feature a two-stage power topology with synchronous-rectification that greatly improves efficiency and optimizes the power dissipated by the converter.

The high input voltage NiQor® family of DC-DC converters offers unique solutions for converting high‑powered, variable voltages to a wide range of output voltages. The converter is a non-isolated buck‑boost regulator, which employs synchronous rectification to achieve extremely high conversion efficiency. These products are suitable for use in Intermediate Bus Architecture, or to provide a regulated output voltage from a variable voltage source such as a battery. They can be configured to ‘buck’ the input voltage down or ‘boost’ the input voltage up using a single external resistor.

SynQor provides EMI filters for InQor® DC-DC converters. All EMI filters provide high levels of differential-mode and common-mode attenuation and include stabilizing bulk capacitors and damping resistors.

To learn more visit our Product Guide or contact a SynQor representative.

SynQor provides AC Line filters for the Industrial PFC modules and DC-DC converters. SynQor’s high‑performance filters are designed to comply with industry EMI standards.

The PFCQor® Power Factor Correction module is an essential building block of an AC-DC power supply. Used in conjunction with a hold-up capacitor, SynQor’s high efficiency DC-DC converters and SynQor’s AC line filter, the PFCQor will draw a nearly perfect sinusoidal current (PF>0.99) from a single phase AC input. Up to three PFCQor modules can be paralleled to achieve higher power. The module is supplied completely encased to provide protection from the harsh conditions seen in many industrial and transportation environments.

The PFICQor Isolated Power Factor Correction module is a high power, high efficiency AC-DC converter. It operates from a universal AC input and generates an isolated output. Both regulated and semi-regulated (droop version) modules are available. Used in conjunction with a hold-up capacitor, and SynQor’s AC line filter, the PFICQor will draw a nearly perfect sinusoidal current (PF>0.99) from a single phase AC input. The module is supplied completely encased to provide protection from the harsh environments seen in many industrial and transportation environments.

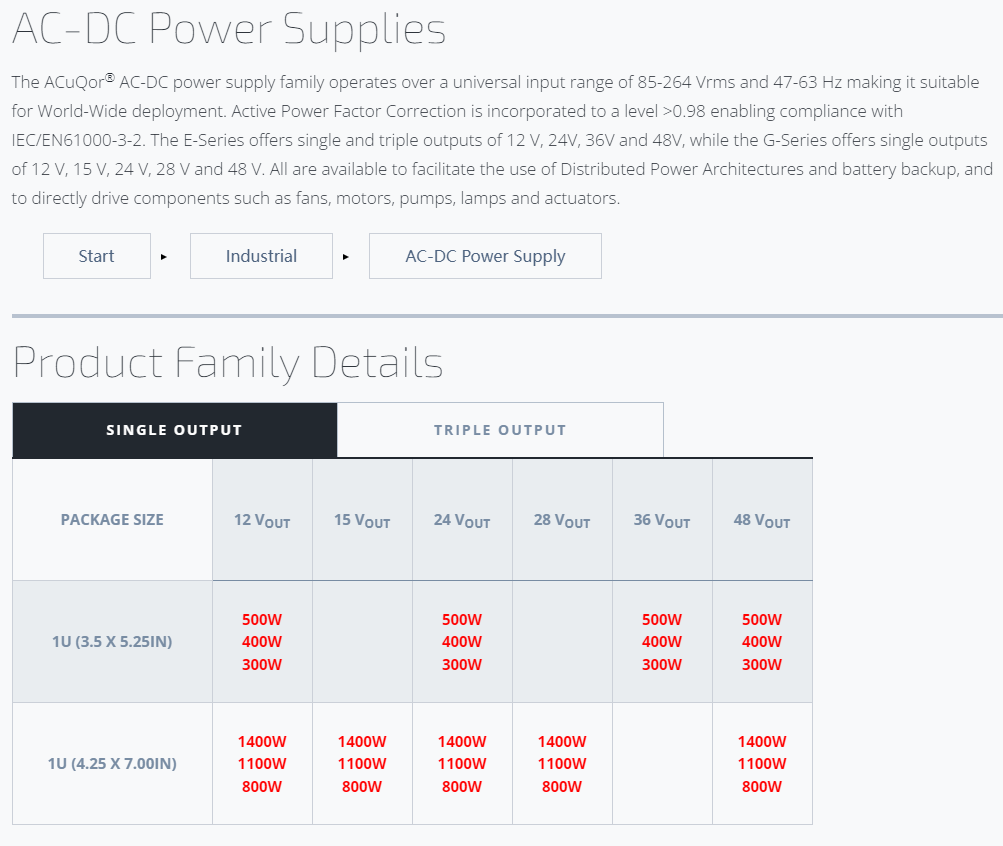

The ACuQor® product line offers best-in-class solutions for AC-DC power supplies designed to meet an extensive range of applications. The E-Series packages 500 W of usable power into just 3.50" x 5.25" x 1.63" (Encased). The G-Series provides 1400 W of usable power in a 4.75" x 7.00" x 1.63" package.

Yes, we retrofit legacy systems (e.g., GE Frame 5, Siemens V94.2) with modern digital controllers, typically completing hardware integration within 4-8 weeks. Software migration requires additional validation time.

We recommend annual performance testing under ISO 3977-2 standards. Critical applications (e.g., offshore platforms) may require semi-annual tests with emissions compliance checks.

All rad-hard devices (e.g., FPGA, ADC) are QML Class V certified under MIL-PRF-38535 and tested to MIL-STD-883 Method 1019 for SEU tolerance. Full qualification reports are available upon request.

Our ASICs and power management ICs operate across -55°C to +175°C ambient temperatures, with derating curves provided in military temperature range (MTR) datasheets.

Our PMA parts (e.g., actuators, sensors) hold FAA/EASA Form 1 certification and match OEM form/fit/function. Installation requires SB/MB documentation per FAA AC 23.1529.

All NAS/MS fasteners include full DNA traceability: melt source (AMS 2301), heat/lot numbers, and AS9100-compliant MTRs with ultrasonic test reports.

AOG orders ship within 4 hours for stocked items (FAA-PMA, EASA Part 21G). Non-stock critical parts trigger priority manufacturing with 72-hour max turnaround.

Gas Turbine

Gas Turbine

Aircraft parts

Aircraft parts