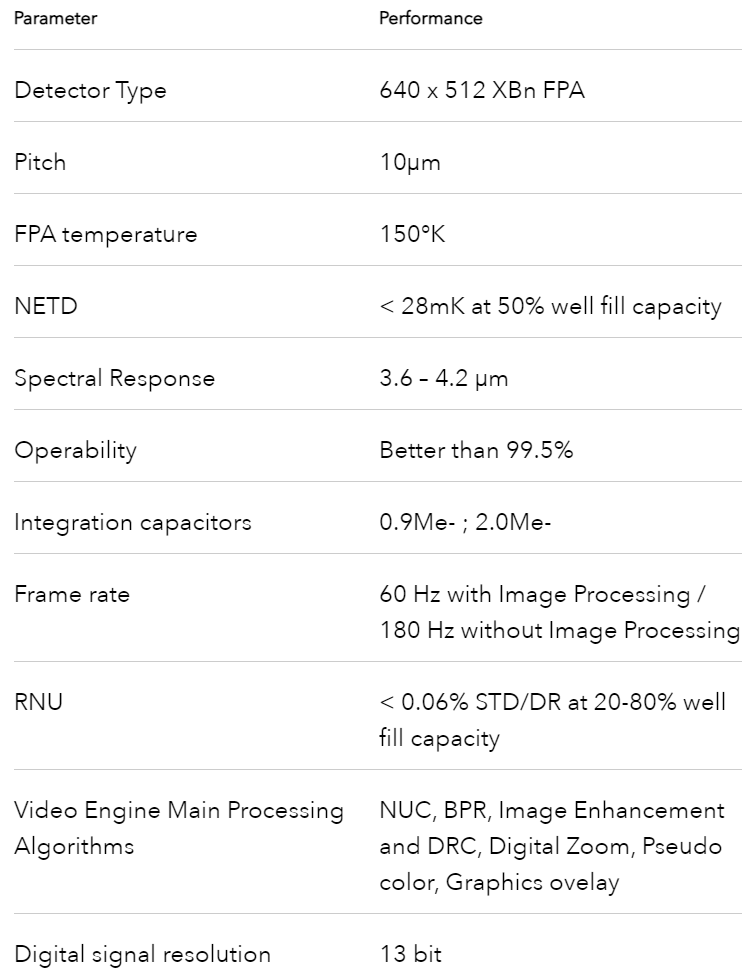

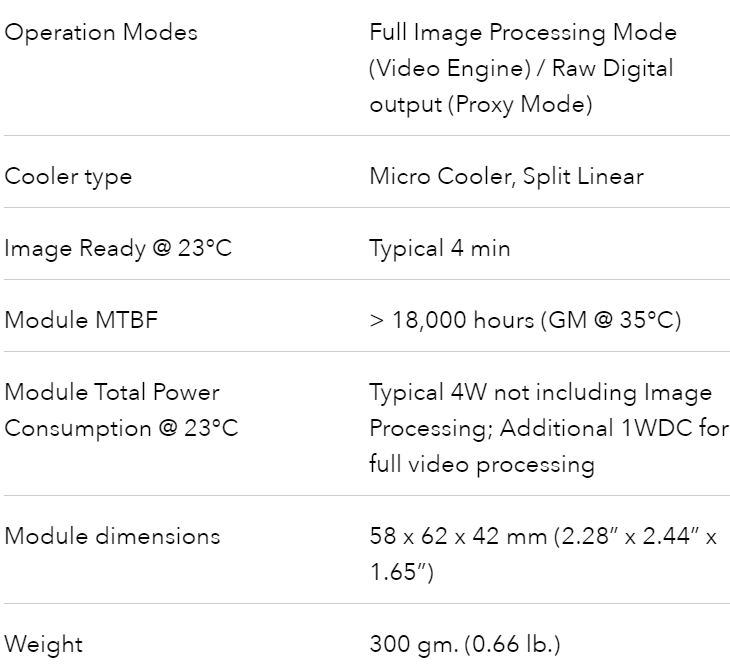

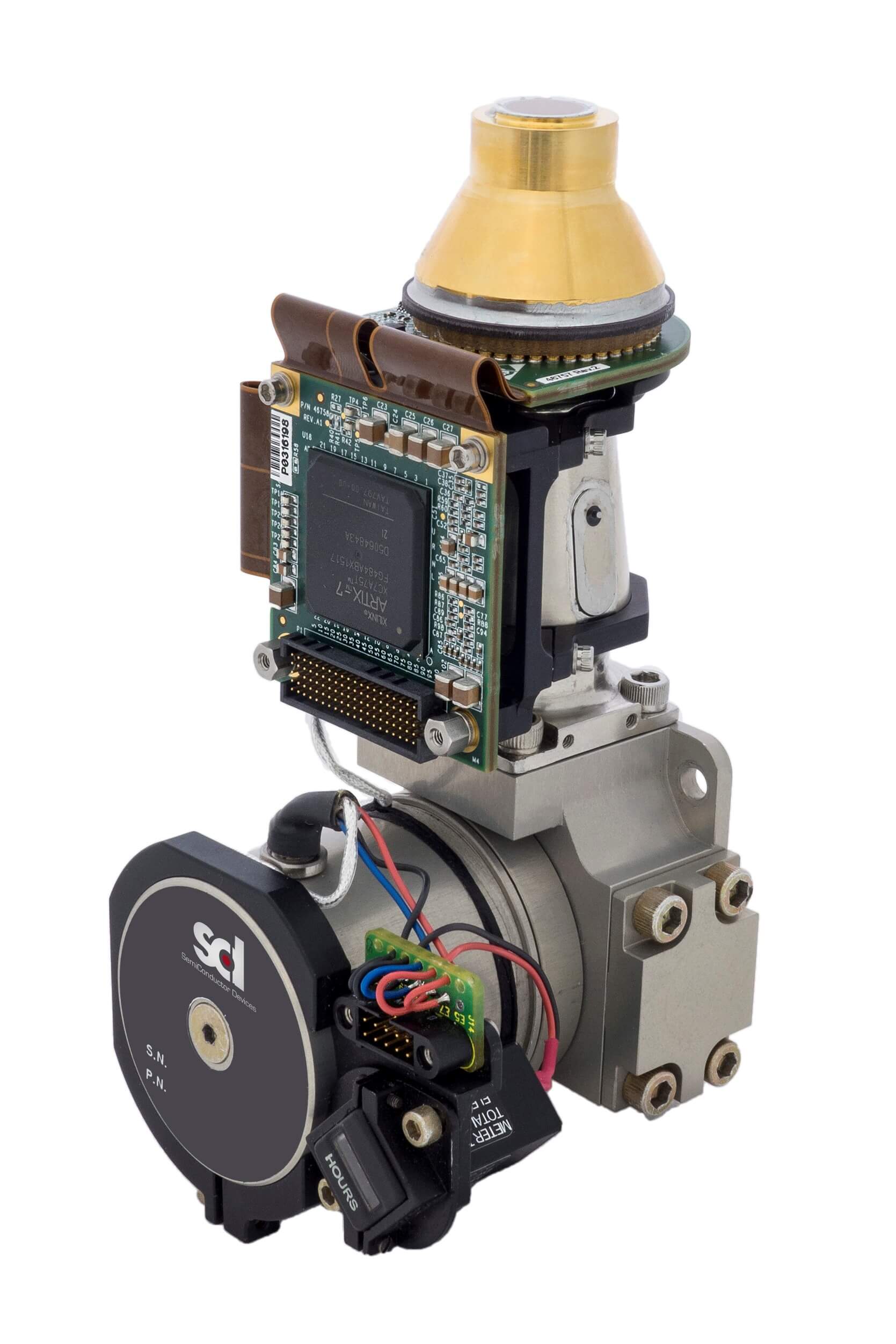

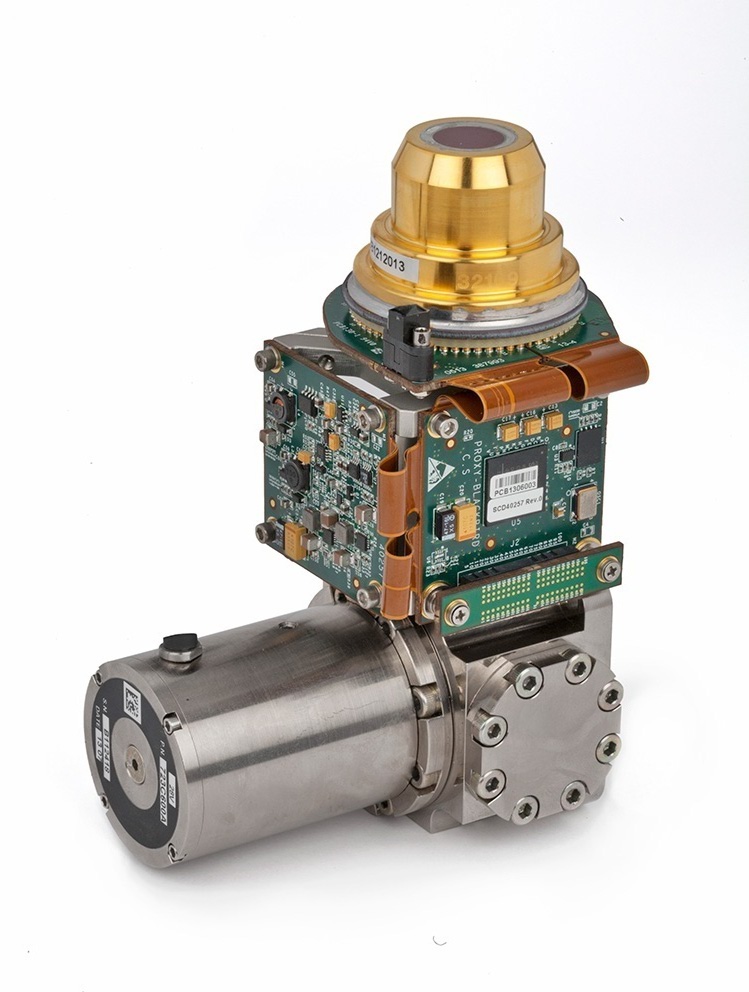

The Sparrow is a low cost and low SWaP MWIR camera core designed for the demanding requirements of wide distribution market applications such as handheld thermal systems and miniature payloads for drones or long range thermal weapon system for snipers. The Sparrow uses a state-of-the-art HOT Blackbird FPA which is integrated into a compact and novel Dewar and cooler architecture. These elements are ssembled in a compact manner that also includes low power electronics. The Sparrow electronics has multiple capabilities including FPA control, cooler driver & control, and a complete set of video processing features. This 640×512 FPA is based on SCD’s mature and field proven XBn (HOT) technology operating at 150K with 10μm pixel pitch. It includes a Digital readout integrated circuit (ROIC) implemented in advanced CMOS process. Combining these two elements yields outstanding image quality.

The 10μm pitch FPA overall size is about 55% smaller than common VGA solutions based on 15μm pitch pixel which enable the user to reduce the size & weight of the system optics. The combination of this miniature FPA with its high operating temperature enables optimization of the cooler and Dewar for low SWaP applications. Another important advantage of the Sparrow is its long life time that is based upon linear engine technology combined with the HOT FPA technology.

Yes, we retrofit legacy systems (e.g., GE Frame 5, Siemens V94.2) with modern digital controllers, typically completing hardware integration within 4-8 weeks. Software migration requires additional validation time.

We recommend annual performance testing under ISO 3977-2 standards. Critical applications (e.g., offshore platforms) may require semi-annual tests with emissions compliance checks.

All rad-hard devices (e.g., FPGA, ADC) are QML Class V certified under MIL-PRF-38535 and tested to MIL-STD-883 Method 1019 for SEU tolerance. Full qualification reports are available upon request.

Our ASICs and power management ICs operate across -55°C to +175°C ambient temperatures, with derating curves provided in military temperature range (MTR) datasheets.

Our PMA parts (e.g., actuators, sensors) hold FAA/EASA Form 1 certification and match OEM form/fit/function. Installation requires SB/MB documentation per FAA AC 23.1529.

All NAS/MS fasteners include full DNA traceability: melt source (AMS 2301), heat/lot numbers, and AS9100-compliant MTRs with ultrasonic test reports.

AOG orders ship within 4 hours for stocked items (FAA-PMA, EASA Part 21G). Non-stock critical parts trigger priority manufacturing with 72-hour max turnaround.

Gas Turbine

Gas Turbine

Aircraft parts

Aircraft parts