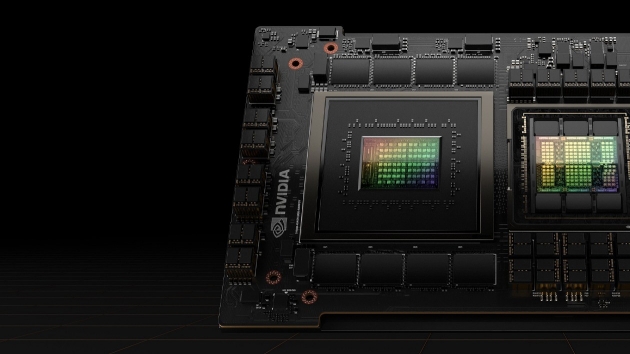

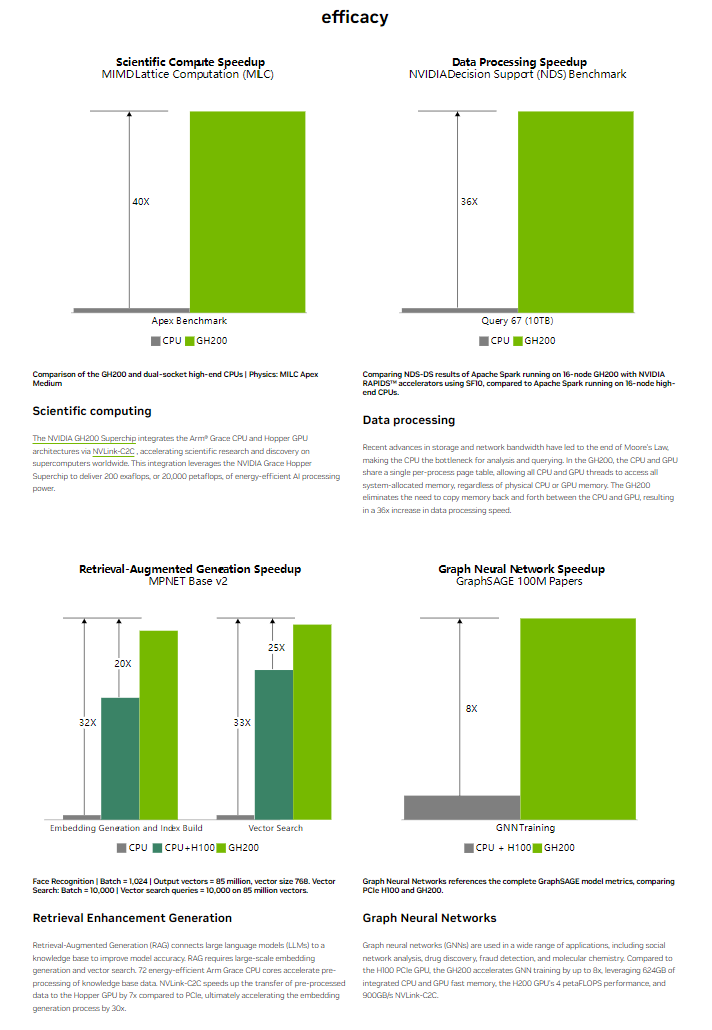

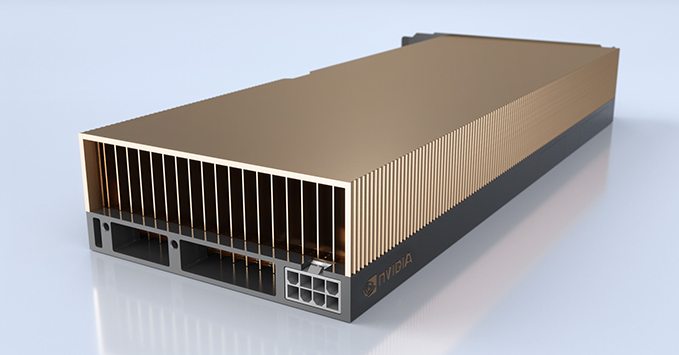

The NVIDIA GH200 Grace Hopper™ superchip is a breakthrough processor for AI , high-performance computing (HPC) intelligence, and high-performance computing (HPC) applications. This superchip delivers 10x the performance for applications running terabytes of data, providing an unmatched solution for scientists and researchers to solve the world's most complex problems.

The GH200 Grace Hopper Superchip uses NVIDIA NVLink™-C2C to integrate the NVIDIA Grace™ and Hopper™ architectures, providing a CPU+GPU coherent memory model suitable for accelerating artificial intelligence and high-performance computing applications. This superchip features a 900GB/s coherent interface, which is 7 times faster than PCIe Gen5. In addition, this chip is equipped with HBM3 and HBM3e GPU memory, which significantly improves the performance of accelerated computing and generative artificial intelligence. The GH200 runs all NVIDIA software stacks and platforms, including NVIDIA AI Enterprise, HPC SDK, and Omniverse™

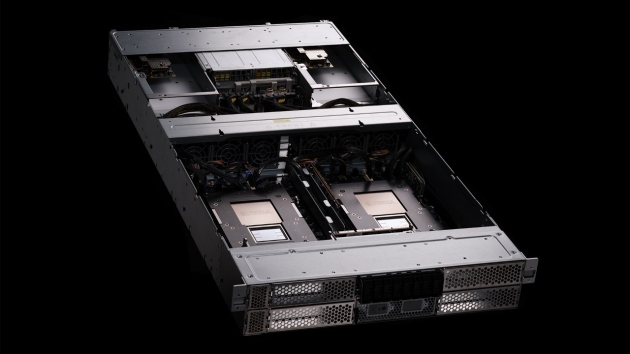

The NVIDIA GH200 NVL2 fully connects two GH200 superchips via NVLink, delivering 288GB of high-bandwidth memory, 10 TB/s of memory bandwidth, and 1.2TB of fast memory. Available now, the GH200 NVL2 offers up to 3.5 times the GPU memory capacity and 3 times the bandwidth compared to the NVIDIA H100 Tensor Core GPU, making it ideal for compute- and memory-intensive workloads.

Yes, we retrofit legacy systems (e.g., GE Frame 5, Siemens V94.2) with modern digital controllers, typically completing hardware integration within 4-8 weeks. Software migration requires additional validation time.

We recommend annual performance testing under ISO 3977-2 standards. Critical applications (e.g., offshore platforms) may require semi-annual tests with emissions compliance checks.

All rad-hard devices (e.g., FPGA, ADC) are QML Class V certified under MIL-PRF-38535 and tested to MIL-STD-883 Method 1019 for SEU tolerance. Full qualification reports are available upon request.

Our ASICs and power management ICs operate across -55°C to +175°C ambient temperatures, with derating curves provided in military temperature range (MTR) datasheets.

Our PMA parts (e.g., actuators, sensors) hold FAA/EASA Form 1 certification and match OEM form/fit/function. Installation requires SB/MB documentation per FAA AC 23.1529.

All NAS/MS fasteners include full DNA traceability: melt source (AMS 2301), heat/lot numbers, and AS9100-compliant MTRs with ultrasonic test reports.

AOG orders ship within 4 hours for stocked items (FAA-PMA, EASA Part 21G). Non-stock critical parts trigger priority manufacturing with 72-hour max turnaround.

Gas Turbine

Gas Turbine

Aircraft parts

Aircraft parts