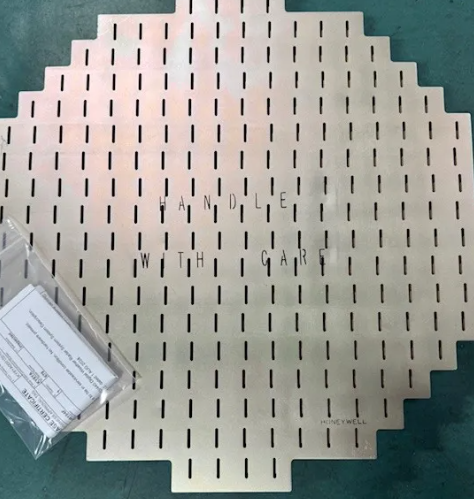

Honeywell has designed and tailored many military application auxiliary power units. This line of products started with the 85 series auxiliary power units supporting the C-130 cargo aircraft all the way up to the most recent fighter applications with the G250 auxiliary power unit, supporting the F22, and the G230 auxiliary power unit, supporting the F35 Joint Strike Fighter. Not to forget, Honeywell continues to support the defense helicopter applications from attack helicopters like the Apache AH-64 with the 36-155 auxiliary power unit up to utility applications with the Blackhawk UH-60 with the 36-150BH and the Chinook CH-47 with the 36-150CH.

Honeywell’s broad auxiliary power unit model scale has enabled secondary power solutions for fixed wing, rotor wing and even ground cart applications that support global military logistics. If there is a secondary power need, Honeywell has a solution!

GTCP 36-150 auxiliary power unit for helicopters:

The model 36-150 auxiliary power unit is a single-shaft, constant speed gas turbine engine, providing shaft and pneumatic power for ground and airborne applications. The auxiliary power unit is designed to deliver compressed air for main engine starting, air conditioning, anti-ice and heating systems. Shaft power is typically used to drive AC/DC generators, hydraulic pumps, cooling fans and accessory transmissions. The 36-150 is capable of delivering air and shaft power simultaneously or individually. The 36-150 auxiliary power unit family encompasses more than 20 different variations modified for specific military (or commercial aircraft) application requirements.

Yes, we retrofit legacy systems (e.g., GE Frame 5, Siemens V94.2) with modern digital controllers, typically completing hardware integration within 4-8 weeks. Software migration requires additional validation time.

We recommend annual performance testing under ISO 3977-2 standards. Critical applications (e.g., offshore platforms) may require semi-annual tests with emissions compliance checks.

All rad-hard devices (e.g., FPGA, ADC) are QML Class V certified under MIL-PRF-38535 and tested to MIL-STD-883 Method 1019 for SEU tolerance. Full qualification reports are available upon request.

Our ASICs and power management ICs operate across -55°C to +175°C ambient temperatures, with derating curves provided in military temperature range (MTR) datasheets.

Our PMA parts (e.g., actuators, sensors) hold FAA/EASA Form 1 certification and match OEM form/fit/function. Installation requires SB/MB documentation per FAA AC 23.1529.

All NAS/MS fasteners include full DNA traceability: melt source (AMS 2301), heat/lot numbers, and AS9100-compliant MTRs with ultrasonic test reports.

AOG orders ship within 4 hours for stocked items (FAA-PMA, EASA Part 21G). Non-stock critical parts trigger priority manufacturing with 72-hour max turnaround.

Gas Turbine

Gas Turbine

Aircraft parts

Aircraft parts