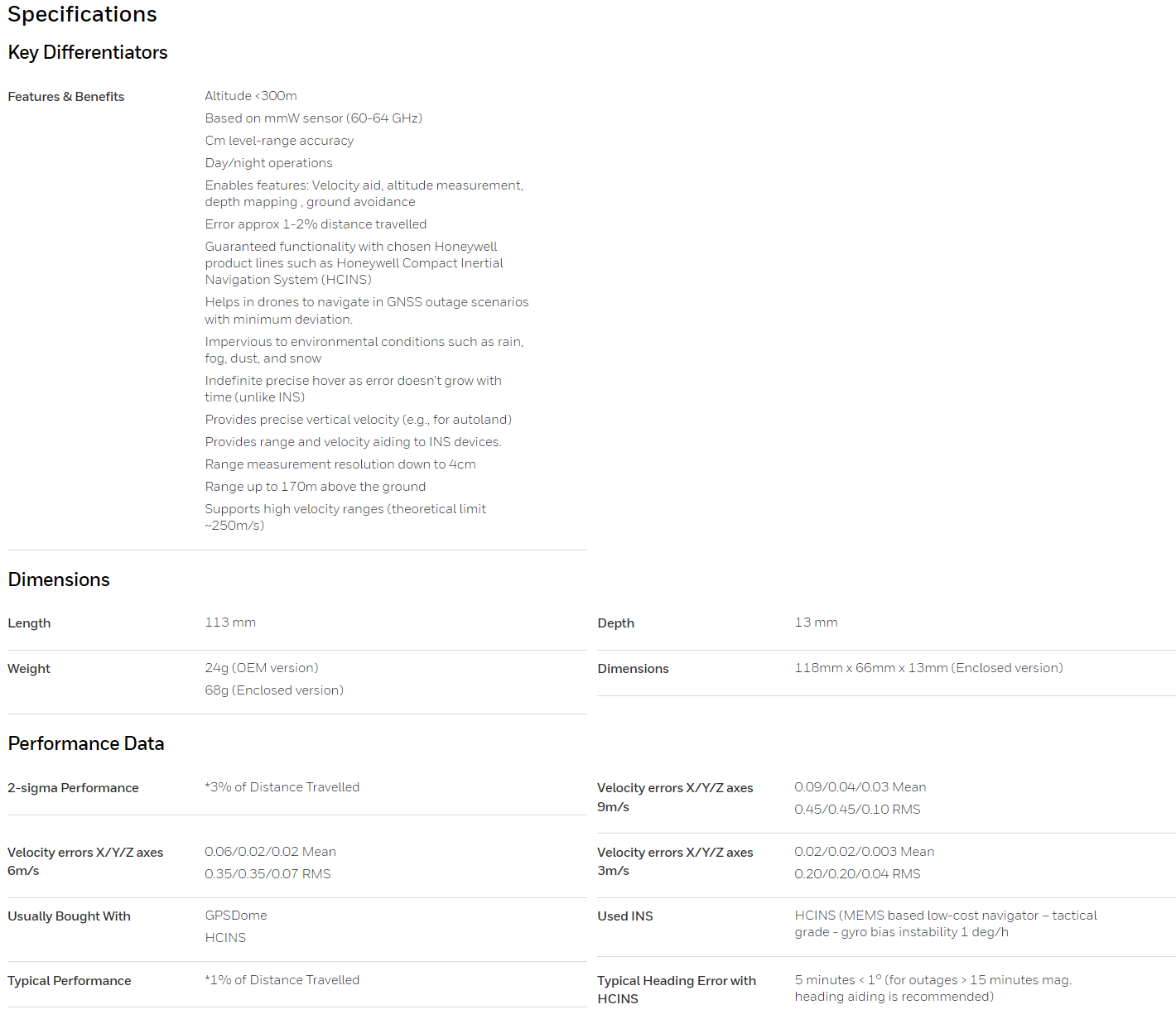

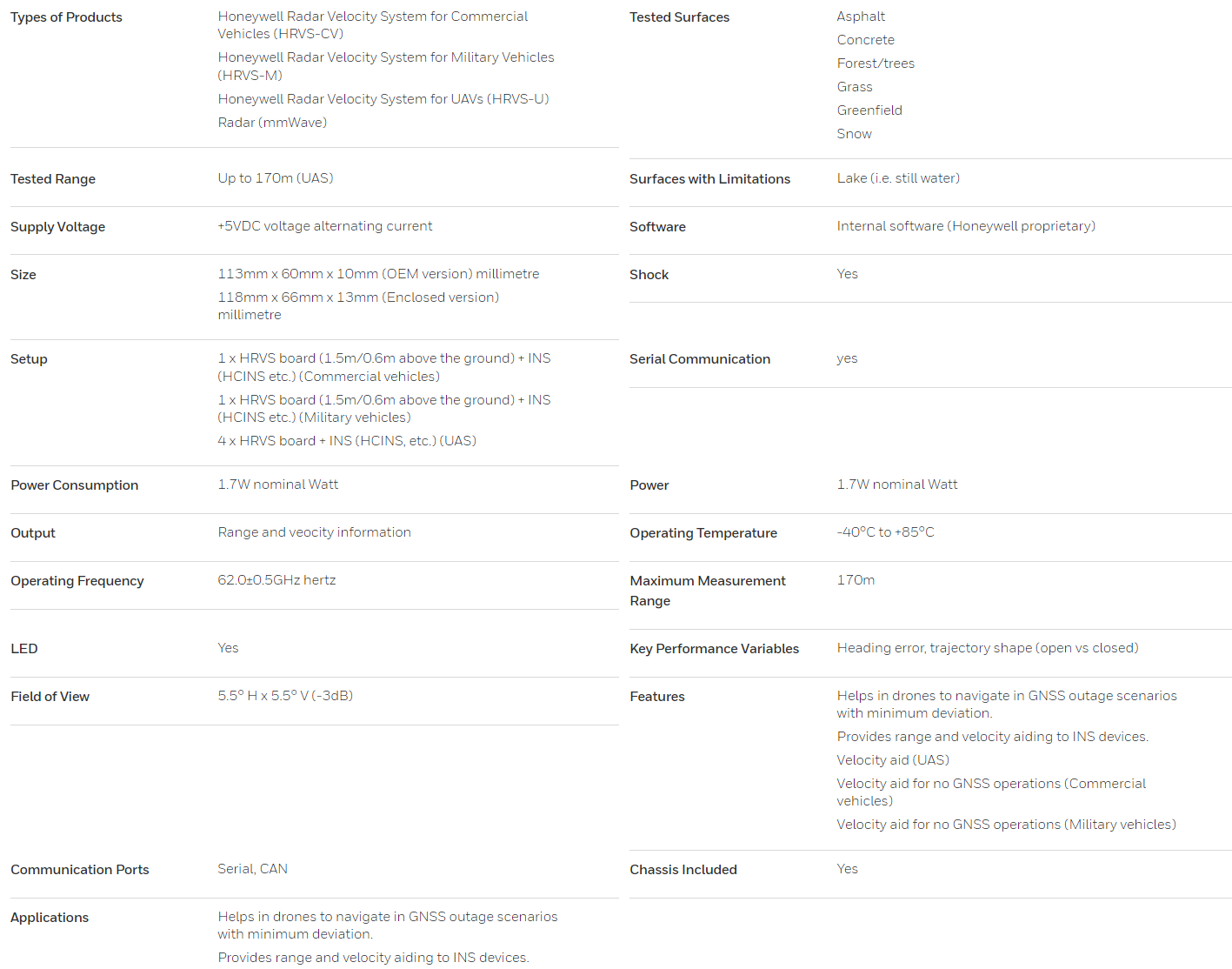

The Honeywell Radar Velocity System (HRVS) is a small, lightweight, low-power radar-based navigation-aiding system. It uses millimeter wave sensing technology (60-64GHz or 76-81 GHz) providing range, velocity, and angle of objects. The HRVS can provide cm level-range accuracy and is impervious to environmental conditions such as rain, fog, dust, and snow.

Our HRVS can be used either as a velocity aiding source to inertial navigation systems or as an independent velocity sensing system in commercial and military applications.

Radar Velocity System Applications:

While the primary purpose of HRVS is to be an aiding source to inertial navigation systems, we can use HRVS also as a speed sensor or as a proximity warning system. Some of the applications where HRVS can be used are:

• Commercial Vehicles

• Military Vehicles

• Unmanned Aerial Systems

Key Honeywell Advantages

• Based on mmW sensor (60-64 GHz)

• Altitude <300m

• Indefinite precise hover as error doesn’t grow with time (unlike INS)

• Error approx. 1-2% distance travelled

• Cm level-range accuracy

• Impervious to environmental conditions such as rain, fog, dust, and snow

Honeywell Radar Velocity System for UAVs (HRVS-U)

This system consists of 4 HRVS-U units that provides velocity data to INS. Some of the features include altimeter measurement, depth mapping and ground avoidance sensing. Our HRVS-U is tested up to a maximum altitude of 300m and hence is an ideal solution for low-flying BVLOS operations.

Honeywell Radar Velocity System for Military Vehicles (HRVS-M)

The HRVS-M can be a good alternative to military vehicles that need to operate in GNSS-denied environments. Its low emission makes it almost undetectable even at close ranges. Emission data will be provided on request.

Honeywell Radar Velocity System for Commercial Vehicles (HRVS-CV)

In addition to its use as a navigation aid, the HRVS-CV can also be used as a speed sensor for niche commercial vehicles – especially long trailers. This system consists of one HRVS-CV unit which is fixed up to 1.5m above ground.

Yes, we retrofit legacy systems (e.g., GE Frame 5, Siemens V94.2) with modern digital controllers, typically completing hardware integration within 4-8 weeks. Software migration requires additional validation time.

We recommend annual performance testing under ISO 3977-2 standards. Critical applications (e.g., offshore platforms) may require semi-annual tests with emissions compliance checks.

All rad-hard devices (e.g., FPGA, ADC) are QML Class V certified under MIL-PRF-38535 and tested to MIL-STD-883 Method 1019 for SEU tolerance. Full qualification reports are available upon request.

Our ASICs and power management ICs operate across -55°C to +175°C ambient temperatures, with derating curves provided in military temperature range (MTR) datasheets.

Our PMA parts (e.g., actuators, sensors) hold FAA/EASA Form 1 certification and match OEM form/fit/function. Installation requires SB/MB documentation per FAA AC 23.1529.

All NAS/MS fasteners include full DNA traceability: melt source (AMS 2301), heat/lot numbers, and AS9100-compliant MTRs with ultrasonic test reports.

AOG orders ship within 4 hours for stocked items (FAA-PMA, EASA Part 21G). Non-stock critical parts trigger priority manufacturing with 72-hour max turnaround.

Gas Turbine

Gas Turbine

Aircraft parts

Aircraft parts