Wholly designed, developed and produced by Safran Aircraft Engines, the M88 powers Dassault Aviation’s Rafale multirole fighter deployed by French armed forces and export customers.

Wholly designed, developed and produced by Safran Aircraft Engines, the M88 powers Dassault Aviation’s Rafale multirole fighter deployed by French armed forces and export customers.

Exceptionally carefree handling to handle a wide range of combat missions.

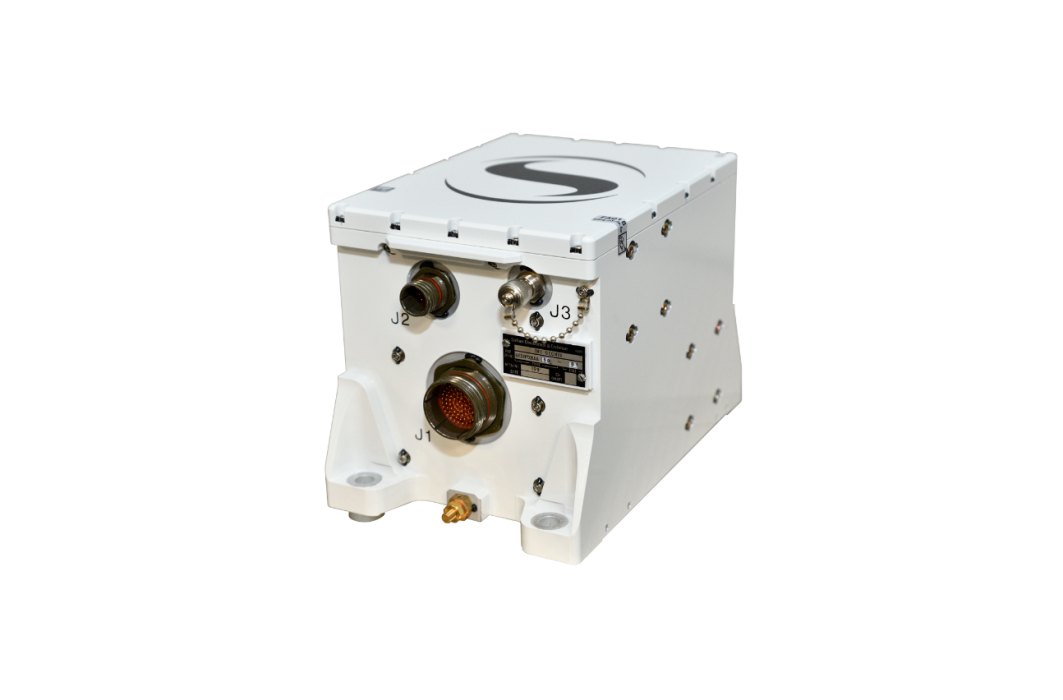

Fully modular design, which facilitates maintenance operations.

An upgradable engine to meet the evolving needs of armed forces.

1 000 000+

total flight-hours

Since it first entered service, the M88 has demonstrated its exceptional capabilities on the Rafale fighters deployed by the French air force and navy. Its performance has also earned export contracts for the Rafale from Egypt, Qatar, India, Greece, Croatia, United Arab Emirates and Indonesia.

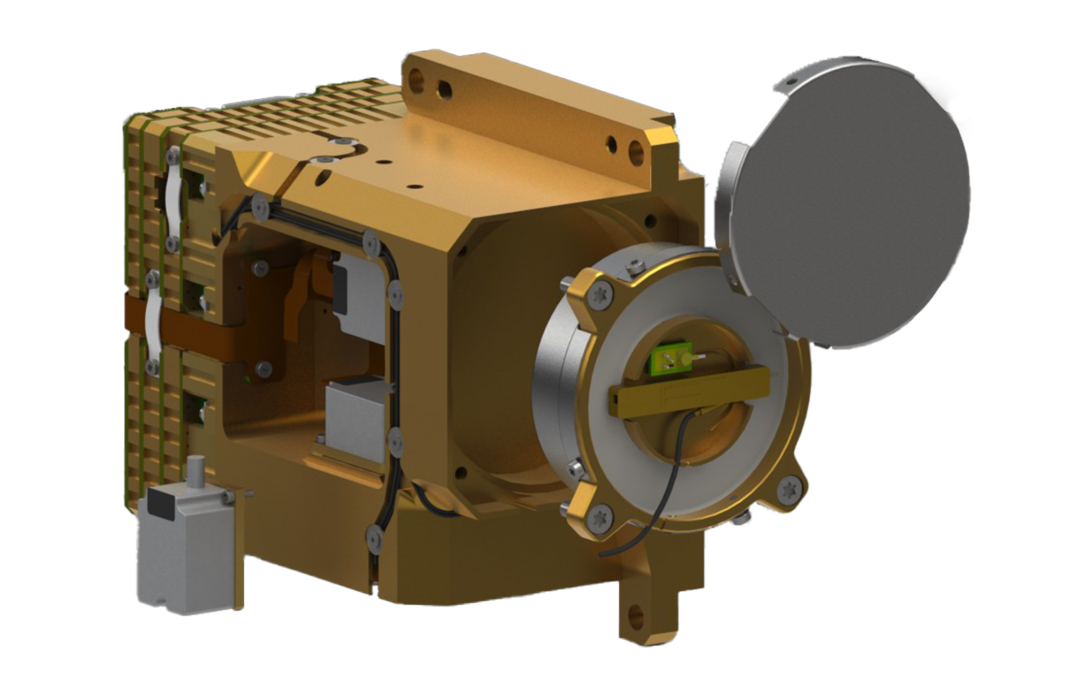

Benefiting from Safran Aircraft Engines’ advanced technologies — such as blisks (integrally bladed disks) and powder-metallurgy disks, single-crystal high-pressure turbine blades with ceramic coatings and thermostructural composites — the M88 has been regularly upgraded.

As a result of the Rafale’s recent sales success, Safran Aircraft Engines has been modernizing its industrial facilities to meet demand from French and export customers. Annual production of the M88 tripled from 2015 to 2020, driven by Industry 4.0 practices and a fully automated assembly line.

Key figures

600+

M88 engines delivered to date

1Hour

time to remove and reinstall a M88

16,500

pounds of thrust with afterburner

Yes, we retrofit legacy systems (e.g., GE Frame 5, Siemens V94.2) with modern digital controllers, typically completing hardware integration within 4-8 weeks. Software migration requires additional validation time.

We recommend annual performance testing under ISO 3977-2 standards. Critical applications (e.g., offshore platforms) may require semi-annual tests with emissions compliance checks.

All rad-hard devices (e.g., FPGA, ADC) are QML Class V certified under MIL-PRF-38535 and tested to MIL-STD-883 Method 1019 for SEU tolerance. Full qualification reports are available upon request.

Our ASICs and power management ICs operate across -55°C to +175°C ambient temperatures, with derating curves provided in military temperature range (MTR) datasheets.

Our PMA parts (e.g., actuators, sensors) hold FAA/EASA Form 1 certification and match OEM form/fit/function. Installation requires SB/MB documentation per FAA AC 23.1529.

All NAS/MS fasteners include full DNA traceability: melt source (AMS 2301), heat/lot numbers, and AS9100-compliant MTRs with ultrasonic test reports.

AOG orders ship within 4 hours for stocked items (FAA-PMA, EASA Part 21G). Non-stock critical parts trigger priority manufacturing with 72-hour max turnaround.

Gas Turbine

Gas Turbine

Aircraft parts

Aircraft parts