deployed on a wide range of military and commercial aircraft and ground applications. Honeywell has manufactured and delivered over 500,000 GG1320 gyros worldwide and over 450,000 HG1700 IMUs.

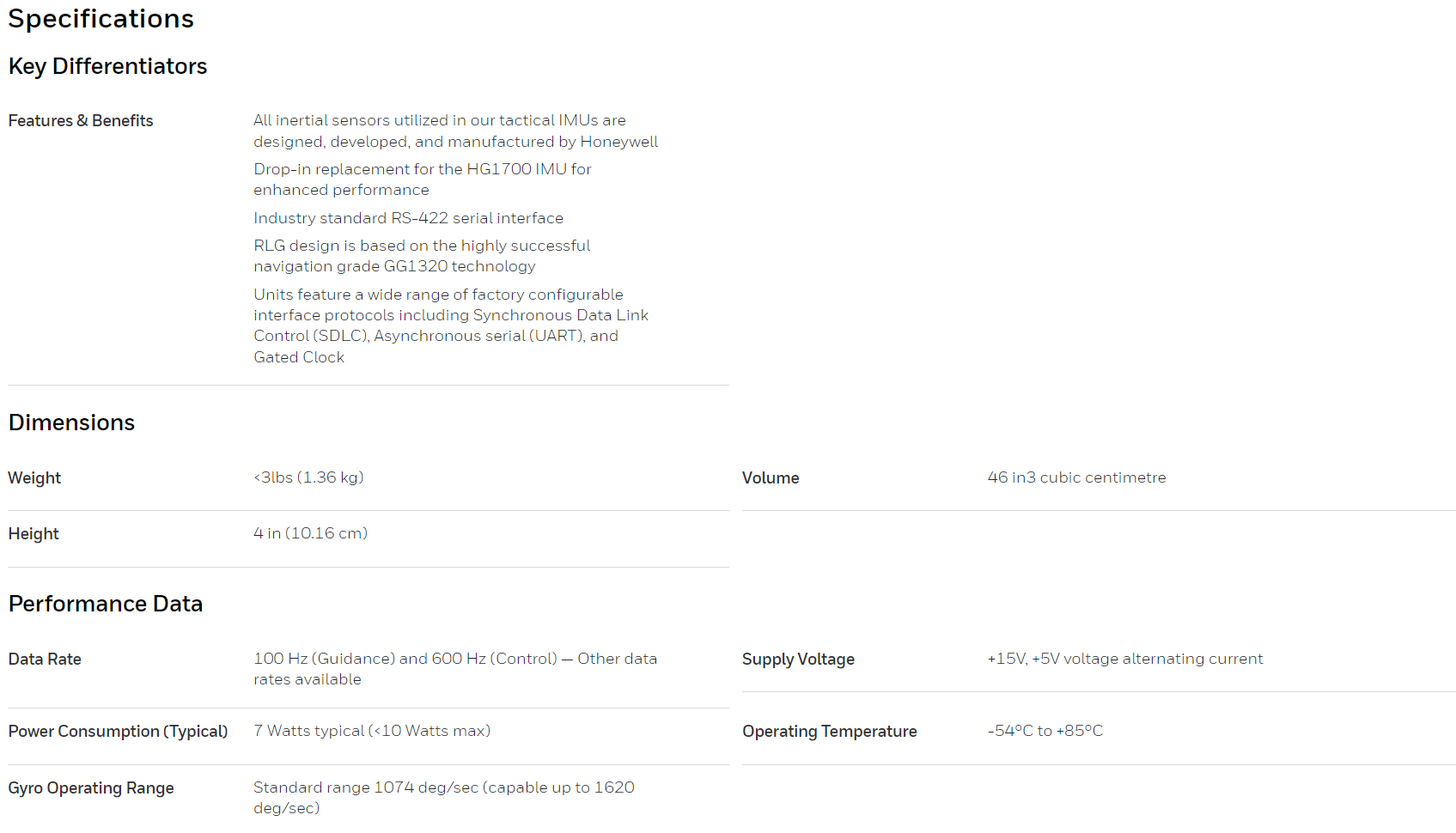

The HG5700 is a product that bridges the performance gap between the HG1700 high performance tactical-grade IMU and the HG9900 high performance navigation-grade IMU. The HG5700 fulfills the need for better performance than the HG1700 at a smaller size and lower cost than the HG9900.

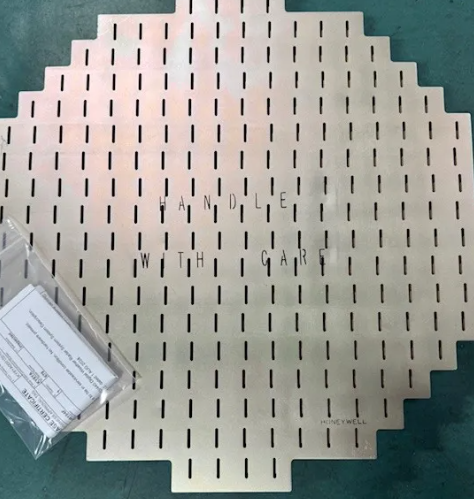

The HG5700’s three Ring Laser Gyroscopes (RLG), three vibrating beam accelerometers (VBA) and associated electronics are all environmentally sealed in rugged aluminum housing. The HG5700 also employs an external environmental ring isolator to filter unwanted sensor inputs commonly encountered in real world applications.

The HG5700 simplifies system integration by offering many configurable features – such as data rate output and flight control filtering. External heat sinks and cooling are not required by HG5700, facilitating greater flexibility in systems design and integration.

The IMU capabilities include up to 3600Hz output, inertial and flight control outputs, internal or external sync, and customizable filters and data output. The INS capabilities include initialization/ transfer align, north finding/ keeping, multiple aiding source input, flight control and navigation output, and is PVT, LOS, and UTC capable.

Yes, we retrofit legacy systems (e.g., GE Frame 5, Siemens V94.2) with modern digital controllers, typically completing hardware integration within 4-8 weeks. Software migration requires additional validation time.

We recommend annual performance testing under ISO 3977-2 standards. Critical applications (e.g., offshore platforms) may require semi-annual tests with emissions compliance checks.

All rad-hard devices (e.g., FPGA, ADC) are QML Class V certified under MIL-PRF-38535 and tested to MIL-STD-883 Method 1019 for SEU tolerance. Full qualification reports are available upon request.

Our ASICs and power management ICs operate across -55°C to +175°C ambient temperatures, with derating curves provided in military temperature range (MTR) datasheets.

Our PMA parts (e.g., actuators, sensors) hold FAA/EASA Form 1 certification and match OEM form/fit/function. Installation requires SB/MB documentation per FAA AC 23.1529.

All NAS/MS fasteners include full DNA traceability: melt source (AMS 2301), heat/lot numbers, and AS9100-compliant MTRs with ultrasonic test reports.

AOG orders ship within 4 hours for stocked items (FAA-PMA, EASA Part 21G). Non-stock critical parts trigger priority manufacturing with 72-hour max turnaround.

Gas Turbine

Gas Turbine

Aircraft parts

Aircraft parts