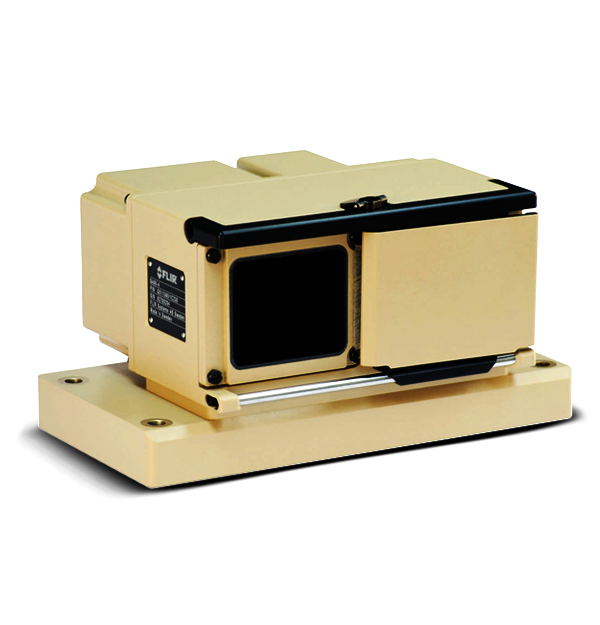

The FLIR Elara™ DX-Series multispectral pan/tilt/zoom (PTZ) security camera provides full situational awareness in the most punishing environments. Combining thermal and visible light imagers, the Elara DX-Series gives operators the ability to monitor large areas in complete darkness, glaring light, and adverse weather. The exceptional detection and identification capabilities of multispectral cameras help integrators provide solutions for challenging imaging problems at critical infrastructure sites and remote facilities.

MULTISPECTRAL IMAGING IN ANY CONDITION

Integrated thermal and visible sensors capture sharp video where other PTZ cameras cannot.

DESIGNED TO WITHSTAND EXTREME ENVIRONMENTS

Built to handle the challenges of critical infrastructure sites and other demanding locations.

SUPERIOR MONITORING OF LARGE AREAS AND CHANGING ENVIRONMENTS

PTZ capability gives operators continuous visibility in large areas plus optional thermal zoom up to 5x with 15 mm to 75 mm zoom lens

Yes, we retrofit legacy systems (e.g., GE Frame 5, Siemens V94.2) with modern digital controllers, typically completing hardware integration within 4-8 weeks. Software migration requires additional validation time.

We recommend annual performance testing under ISO 3977-2 standards. Critical applications (e.g., offshore platforms) may require semi-annual tests with emissions compliance checks.

All rad-hard devices (e.g., FPGA, ADC) are QML Class V certified under MIL-PRF-38535 and tested to MIL-STD-883 Method 1019 for SEU tolerance. Full qualification reports are available upon request.

Our ASICs and power management ICs operate across -55°C to +175°C ambient temperatures, with derating curves provided in military temperature range (MTR) datasheets.

Our PMA parts (e.g., actuators, sensors) hold FAA/EASA Form 1 certification and match OEM form/fit/function. Installation requires SB/MB documentation per FAA AC 23.1529.

All NAS/MS fasteners include full DNA traceability: melt source (AMS 2301), heat/lot numbers, and AS9100-compliant MTRs with ultrasonic test reports.

AOG orders ship within 4 hours for stocked items (FAA-PMA, EASA Part 21G). Non-stock critical parts trigger priority manufacturing with 72-hour max turnaround.

Gas Turbine

Gas Turbine

Aircraft parts

Aircraft parts