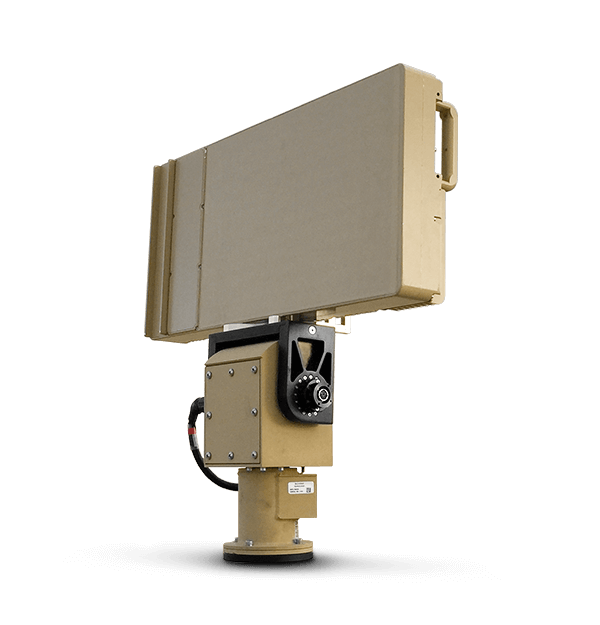

The TacFLIR 280-HDEP is an essential system for ground vehicle surveillance and fixed installations. With an all-new stabilized payload assembly for enhanced reliability, the TacFLIR 280-HDEP is ready for a variety of land missions, and the modular and scalable control electronics unit (CEU) is capable of hosting powerful video processing and Aided Target Recognition (AiTR), as well as third-party algorithms. Designed to meet the rigorous demands of military operations, the system delivers best-in-class EO/IR imagery and optional Display Interface Boards (DIB) which allow the operator to stream up to four independent video streams. In addition, there is also a removable terabyte hard drive w/DVR to record over 80 hours of compressed video and 250 screen captures.

Modular, Scalable Computing Power

Optional high-performance COTS COM Express computing and Graphical Processor Unit for advanced image processing and support of third-party algorithms.

Reliability and Ruggedness

Designed to IP-rating and MIL-STDs for Environmental and EMI, and with improved high-performance electronics to enhance durability, pointing accuracy, whether stationary or on-the-move, and more.

Mission Flexibility

Mission support for ISR on-the-move or stabilized, SAR, covert OPS and more make TacFLIR 280-HDEP an essential system for nearly any scenario.

Yes, we retrofit legacy systems (e.g., GE Frame 5, Siemens V94.2) with modern digital controllers, typically completing hardware integration within 4-8 weeks. Software migration requires additional validation time.

We recommend annual performance testing under ISO 3977-2 standards. Critical applications (e.g., offshore platforms) may require semi-annual tests with emissions compliance checks.

All rad-hard devices (e.g., FPGA, ADC) are QML Class V certified under MIL-PRF-38535 and tested to MIL-STD-883 Method 1019 for SEU tolerance. Full qualification reports are available upon request.

Our ASICs and power management ICs operate across -55°C to +175°C ambient temperatures, with derating curves provided in military temperature range (MTR) datasheets.

Our PMA parts (e.g., actuators, sensors) hold FAA/EASA Form 1 certification and match OEM form/fit/function. Installation requires SB/MB documentation per FAA AC 23.1529.

All NAS/MS fasteners include full DNA traceability: melt source (AMS 2301), heat/lot numbers, and AS9100-compliant MTRs with ultrasonic test reports.

AOG orders ship within 4 hours for stocked items (FAA-PMA, EASA Part 21G). Non-stock critical parts trigger priority manufacturing with 72-hour max turnaround.

Gas Turbine

Gas Turbine

Aircraft parts

Aircraft parts