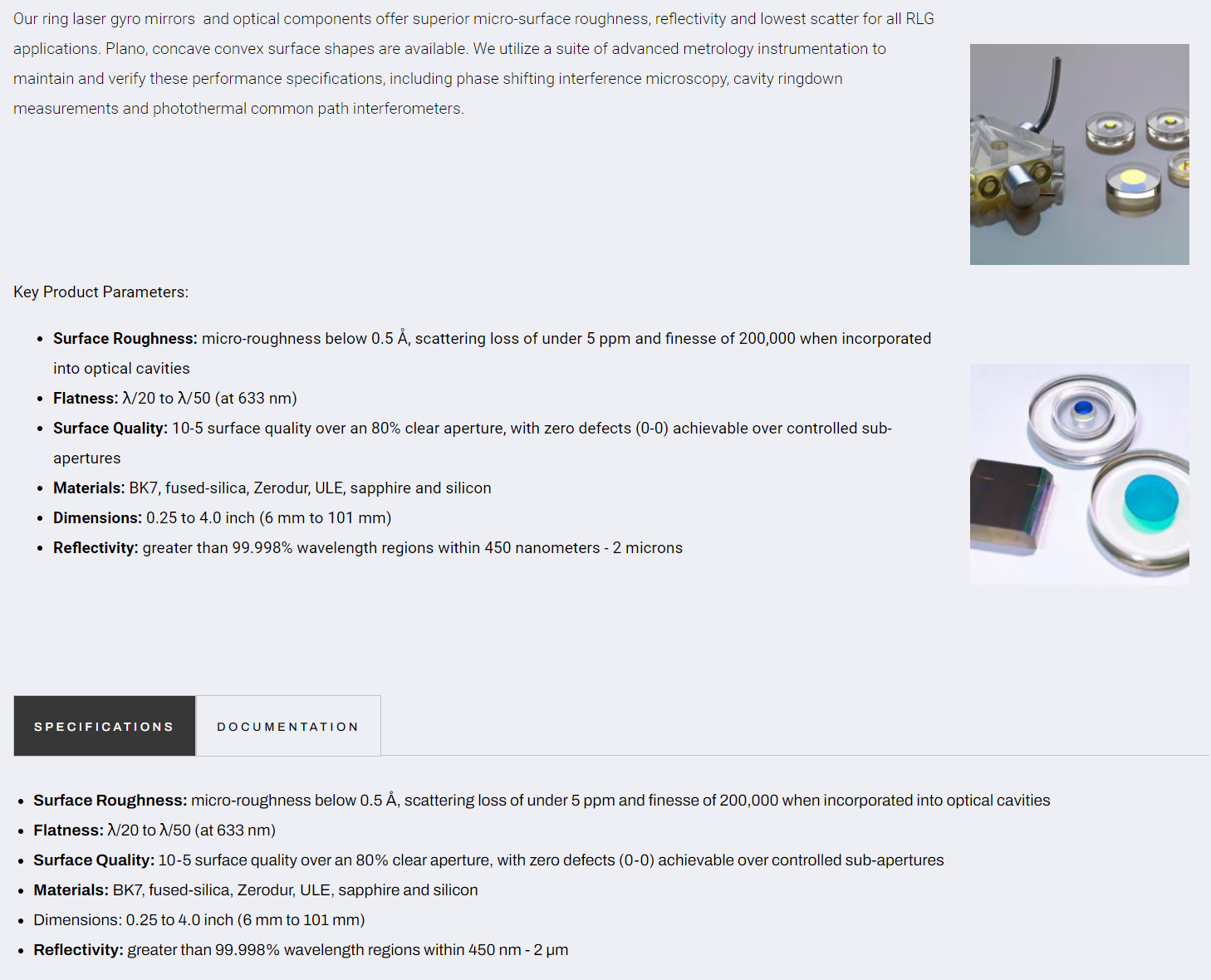

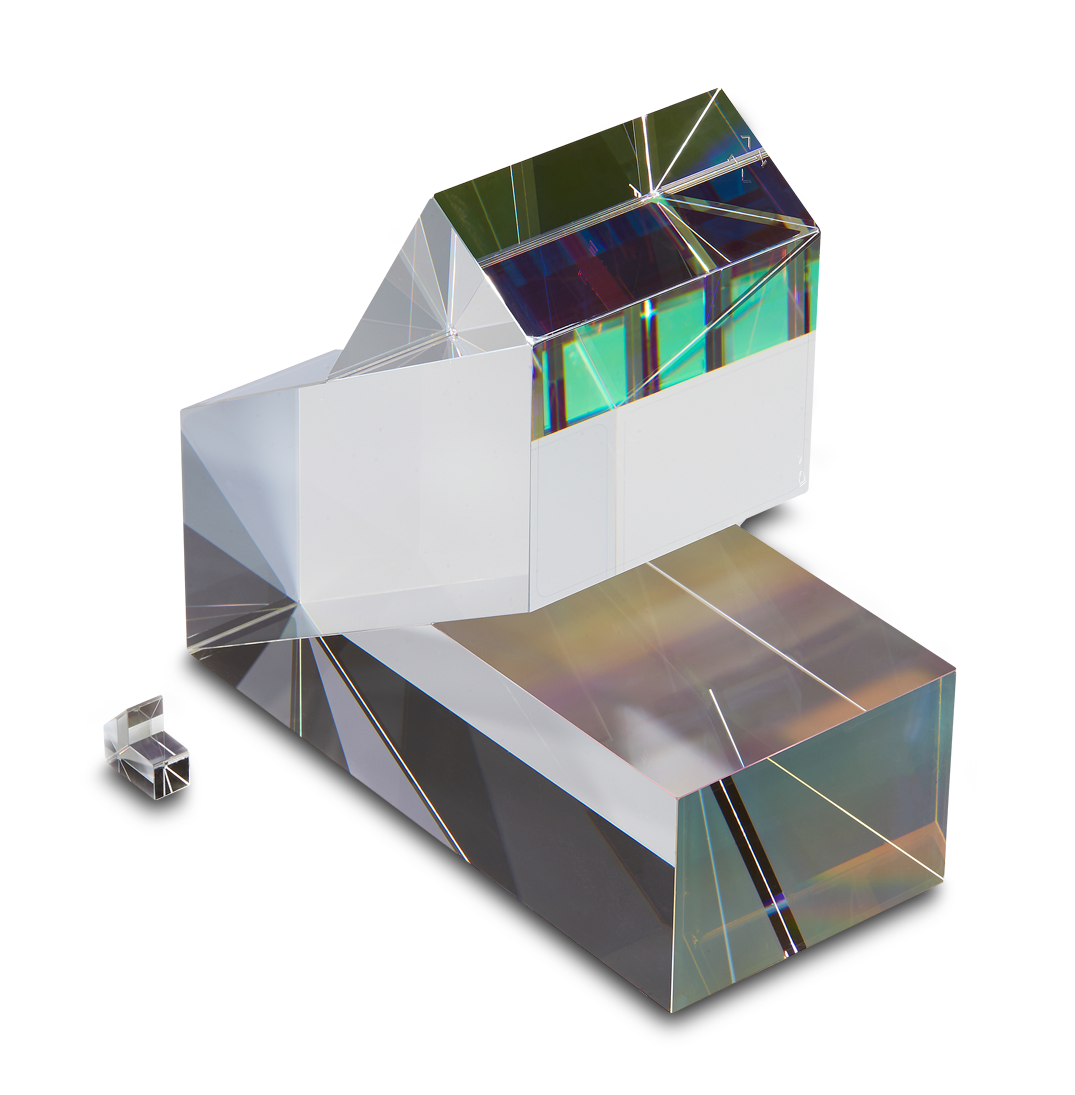

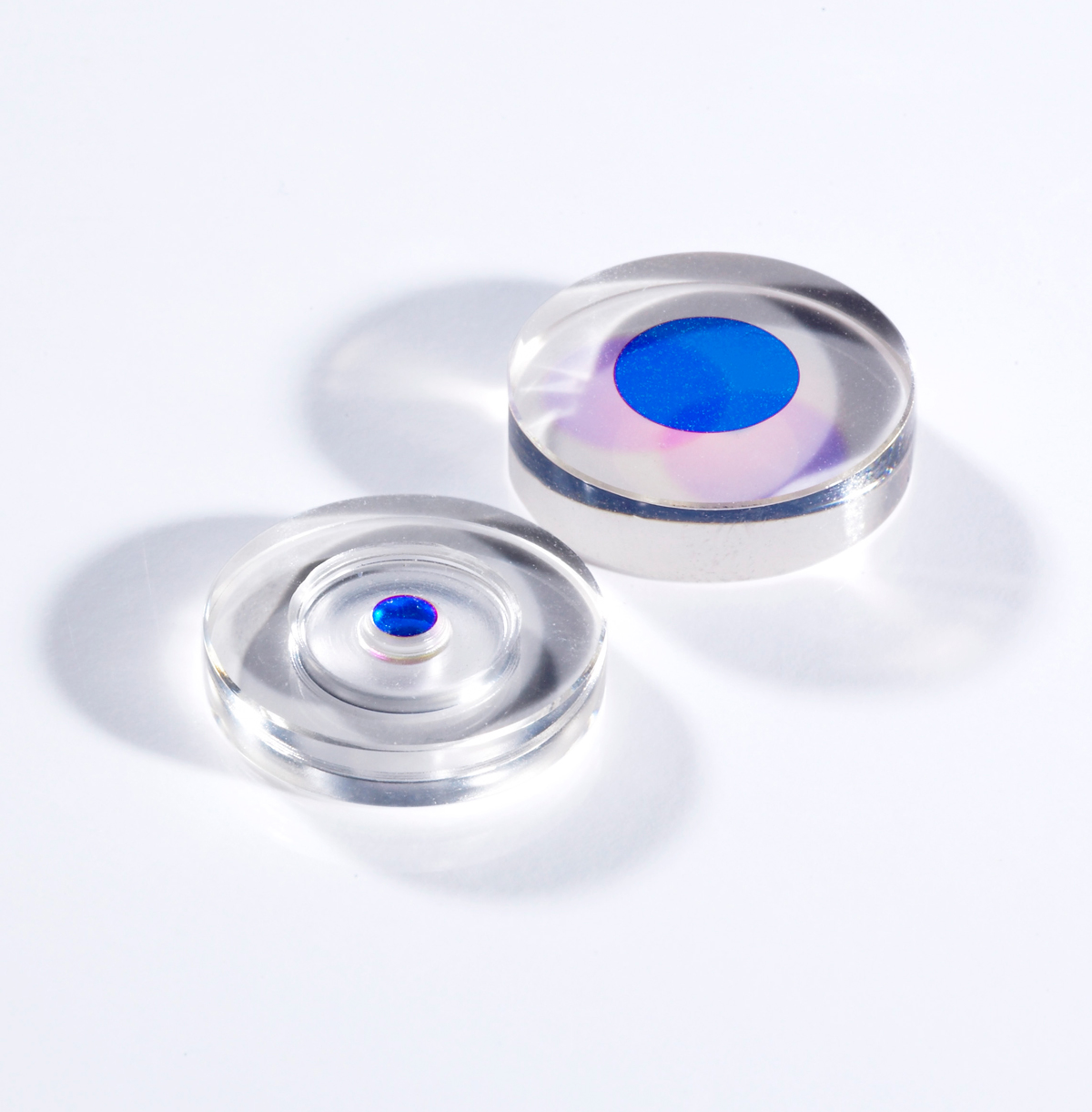

Our ring laser gyroscope optics offer micro-roughness below 0.5 Å, scattering loss of under 5 ppm and finesse of 200,000 when incorporated into optical cavities. Normal superpolished mirrors only reach 100 ppm loss and finesse of 30,000. Our Ion beam sputtered coating’s (IBS) reflectance is greater than 99.998% for 450 nm - 2 µm. Substrate materials include BK7, fused-silica, Zerodur, ULE, sapphire and silicon. Diameters from 0.25 to 4.0 inch (6 mm to 101 mm), flatness’s of λ/20 - λ/50 (at 633 nm), 10-5 surface quality over an 80% clear aperture, and zero defects (0-0) achievable for controlled sub-apertures.

Yes, we retrofit legacy systems (e.g., GE Frame 5, Siemens V94.2) with modern digital controllers, typically completing hardware integration within 4-8 weeks. Software migration requires additional validation time.

We recommend annual performance testing under ISO 3977-2 standards. Critical applications (e.g., offshore platforms) may require semi-annual tests with emissions compliance checks.

All rad-hard devices (e.g., FPGA, ADC) are QML Class V certified under MIL-PRF-38535 and tested to MIL-STD-883 Method 1019 for SEU tolerance. Full qualification reports are available upon request.

Our ASICs and power management ICs operate across -55°C to +175°C ambient temperatures, with derating curves provided in military temperature range (MTR) datasheets.

Our PMA parts (e.g., actuators, sensors) hold FAA/EASA Form 1 certification and match OEM form/fit/function. Installation requires SB/MB documentation per FAA AC 23.1529.

All NAS/MS fasteners include full DNA traceability: melt source (AMS 2301), heat/lot numbers, and AS9100-compliant MTRs with ultrasonic test reports.

AOG orders ship within 4 hours for stocked items (FAA-PMA, EASA Part 21G). Non-stock critical parts trigger priority manufacturing with 72-hour max turnaround.

Gas Turbine

Gas Turbine

Aircraft parts

Aircraft parts