Alternative Navigation Systems

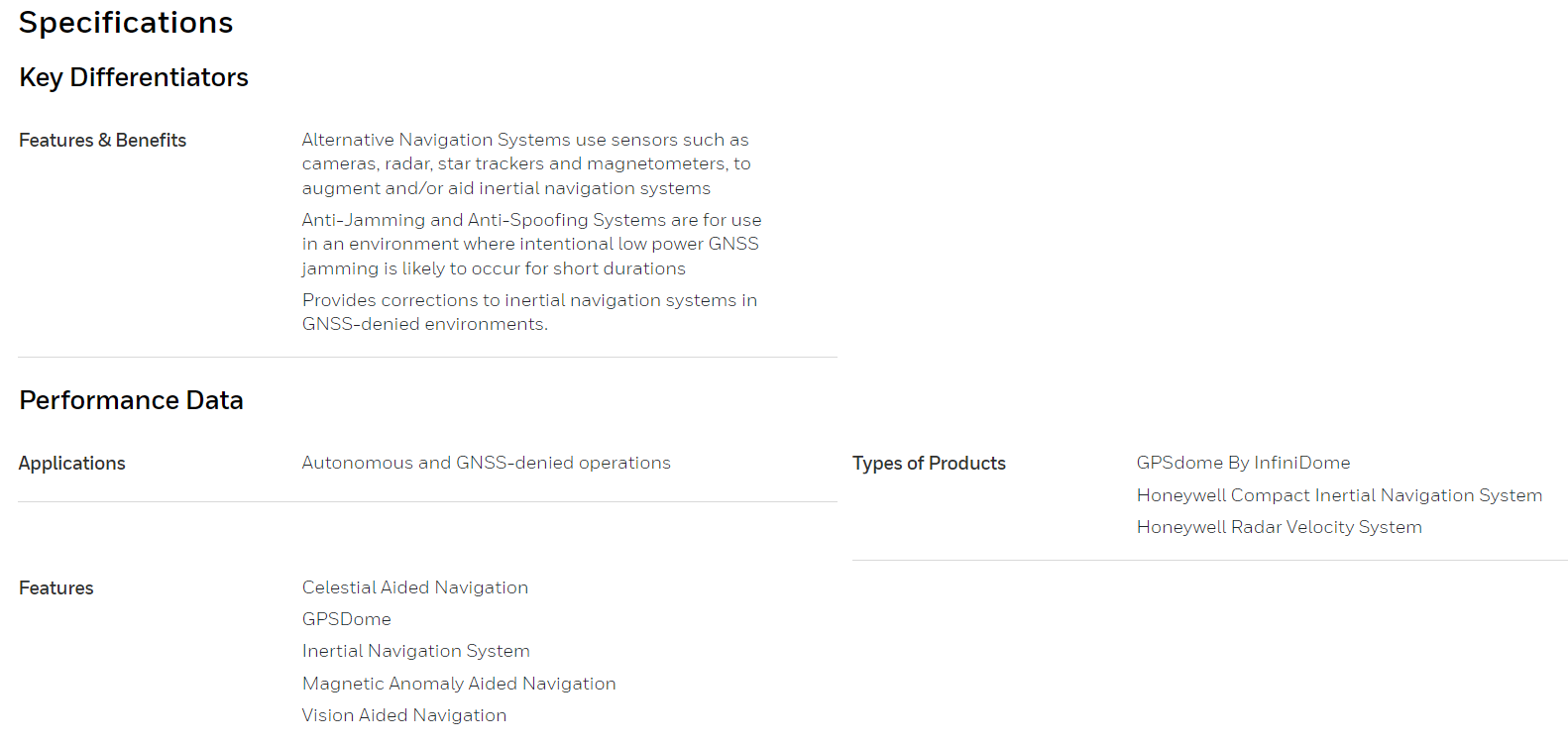

Honeywell’s Alternative Navigation technology enables commercial and military pilots to use sensors such as cameras, LiDAR, radar, radios, and star-trackers to augment and improve INS data. These technologies fill the void when GNSS signals are jammed, blocked, or unavailable. In a traditional INS-GNSS setup, GNSS signals correct errors that cause inertial systems to drift over time. Alternative navigation technologies can support INS in GPS-denied environments.

Honeywell’s Alternative Navigation Offerings include:Vision Navigation:

The Vision Aided Navigation system uses live camera feeds (optical and/or IR) and compares them with maps to provide a passive, un-jammable, highly accurate absolute position. This system was demonstrated on the Embraer E170, achieving GPS-like performance with a horizontal position accuracy of 10m CEP50 during GPS-denied conditions.

Celestial Navigation:

The Celestial Aided Navigation system utilizes star trackers to observe stars and Resident Space Objects (RSOs), providing a passive, un-jammable solution with GPS-like accuracy in GPS-denied or spoofed conditions. This system was recently demonstrated on a land vehicle, achieving an accuracy of 30m CEP50.

Magnetic Anomaly Aided Navigation:

This system measures the Earth's magnetic strength and compares it with magnetic maps to accurately identify the vehicle's position. The technology was successfully demonstrated on the Embraer E170.

Radar Aided Navigation:

Honeywell’s Radar Aided Navigation system uses radars to measure velocity and provide this information to INS, enhancing its accuracy.

Yes, we retrofit legacy systems (e.g., GE Frame 5, Siemens V94.2) with modern digital controllers, typically completing hardware integration within 4-8 weeks. Software migration requires additional validation time.

We recommend annual performance testing under ISO 3977-2 standards. Critical applications (e.g., offshore platforms) may require semi-annual tests with emissions compliance checks.

All rad-hard devices (e.g., FPGA, ADC) are QML Class V certified under MIL-PRF-38535 and tested to MIL-STD-883 Method 1019 for SEU tolerance. Full qualification reports are available upon request.

Our ASICs and power management ICs operate across -55°C to +175°C ambient temperatures, with derating curves provided in military temperature range (MTR) datasheets.

Our PMA parts (e.g., actuators, sensors) hold FAA/EASA Form 1 certification and match OEM form/fit/function. Installation requires SB/MB documentation per FAA AC 23.1529.

All NAS/MS fasteners include full DNA traceability: melt source (AMS 2301), heat/lot numbers, and AS9100-compliant MTRs with ultrasonic test reports.

AOG orders ship within 4 hours for stocked items (FAA-PMA, EASA Part 21G). Non-stock critical parts trigger priority manufacturing with 72-hour max turnaround.

Gas Turbine

Gas Turbine

Aircraft parts

Aircraft parts