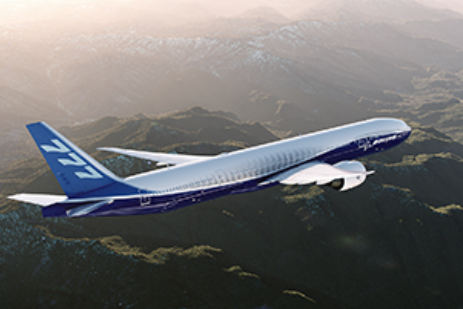

In less than 14 years, the 787 Dreamliner fleet has carried more than one billion passengers, faster than any other widebody jet in aviation history. The airplane’s industry-leading technology creates remarkable opportunities for airlines around the world and dramatically improves the air travel experience. A lighter and robust composite structure enables airlines to reduce fuel use by up to 25 percent compared to the airplanes it replaces. The 787 has unlocked more than 425 new nonstop routes around the world, many of which were never served previously.

On nearly 5 million flights, passengers have an experience like none other in the air. Innovative interiors provide spacious cabins, better views with the largest windows available on any widebody commercial jet today, and cabin enhancements that allow passengers to arrive to their destinations feeling more refreshed.

| 787-8 | 787-9 | 787-10 | |

|---|---|---|---|

| Passengers (two-class) | 248 | 296 | 336 |

| Range nmi (km) | 7,305 nmi (13,530 km) | 7,565 nmi (14,010 km) | 6,330 nmi (11,730 km) |

| Length | 57 m (186 ft) | 63 m (206 ft) | 68 m (224 ft) |

| Wingspan | 60 m (197 ft) | 60 m (197 ft) | 60 m (197 ft) |

| Height | 17 m (56 ft) | 17 m (56 ft) | 17 m (56 ft) |

| Engine | GEnx-1B / Trent 1000 | GEnx-1B / Trent 1000 | GEnx-1B / Trent 1000 |

Yes, we retrofit legacy systems (e.g., GE Frame 5, Siemens V94.2) with modern digital controllers, typically completing hardware integration within 4-8 weeks. Software migration requires additional validation time.

We recommend annual performance testing under ISO 3977-2 standards. Critical applications (e.g., offshore platforms) may require semi-annual tests with emissions compliance checks.

All rad-hard devices (e.g., FPGA, ADC) are QML Class V certified under MIL-PRF-38535 and tested to MIL-STD-883 Method 1019 for SEU tolerance. Full qualification reports are available upon request.

Our ASICs and power management ICs operate across -55°C to +175°C ambient temperatures, with derating curves provided in military temperature range (MTR) datasheets.

Our PMA parts (e.g., actuators, sensors) hold FAA/EASA Form 1 certification and match OEM form/fit/function. Installation requires SB/MB documentation per FAA AC 23.1529.

All NAS/MS fasteners include full DNA traceability: melt source (AMS 2301), heat/lot numbers, and AS9100-compliant MTRs with ultrasonic test reports.

AOG orders ship within 4 hours for stocked items (FAA-PMA, EASA Part 21G). Non-stock critical parts trigger priority manufacturing with 72-hour max turnaround.

Gas Turbine

Gas Turbine

Aircraft parts

Aircraft parts