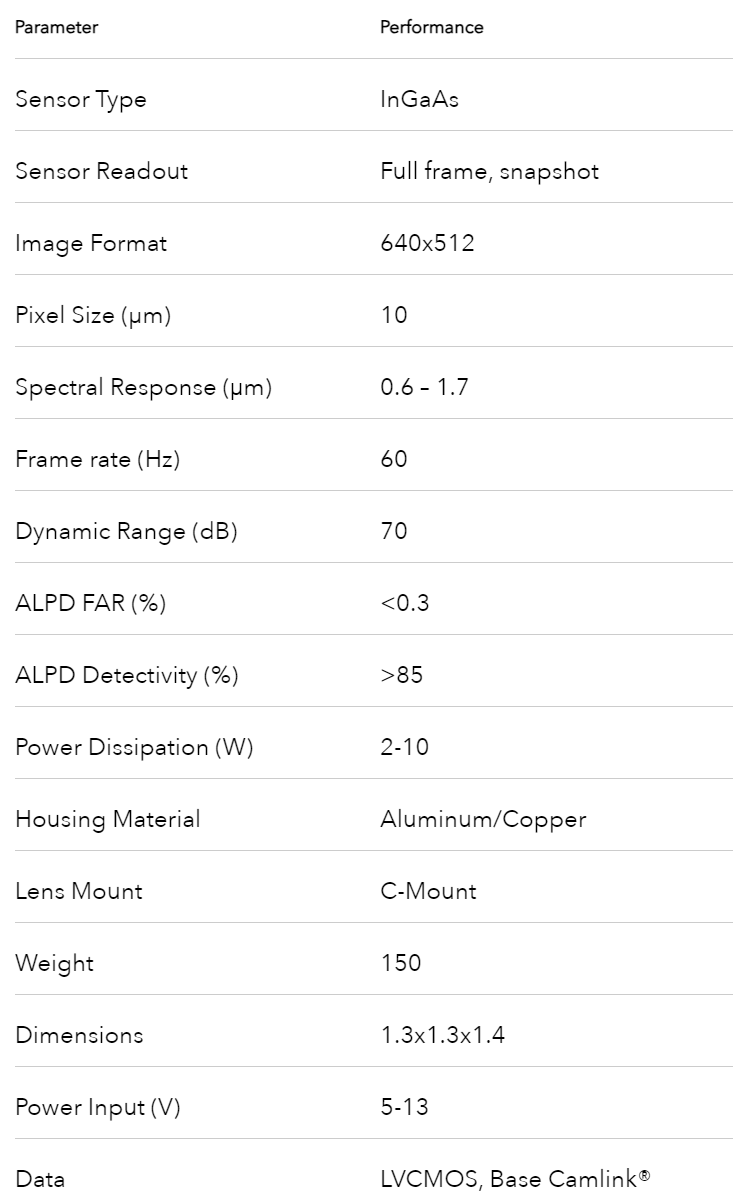

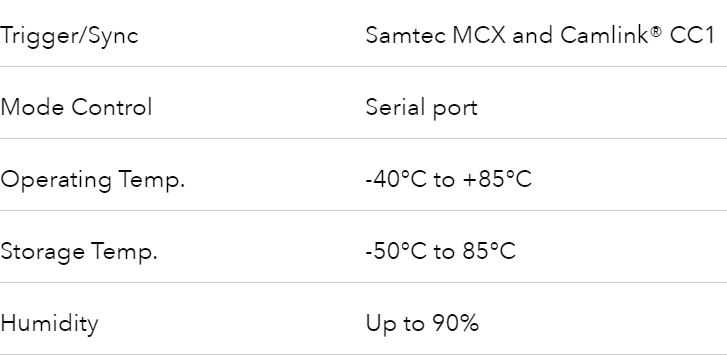

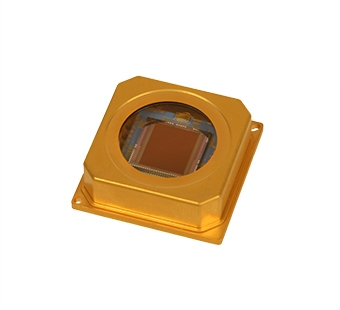

The Mojave 04A-E camera –powered by SCD Swift sensor platform–is a breakthrough in VIS-SWIR imaging, with a low SWaP architecture and capabilities that enable imaging and targeting in harsh environments from -40°C to 85°C. The VGA format camera uses a standard definition 640×512 format InGaAs detector with a 10μm pixel pitch, designed on SCD’s high volume manufacturing platform. Mojave features high-sensitivity and wide dynamic range. It provides real-time imaging with response across the Near Infrared (NIR) through SWIR waveband for passive and active (laser assisted) operation. Built-in Automatic Gain Control (AGC), image enhancement, and Non-Uniformity Correction (NUC) allow for seamless system integration and ease-of-use. Data is provided through either a parallel data connector or a modular Camera Link attachment. Control is accomplished via a serial port interface. The camera also provides the ability to detect and track multiple laser spots in the camera field of view and identify the associated pulse repetition frequency (PRF). Noise and image stability are optimized through proprietary thermal stabilization techniques. The thermal design of the camera ensures operation up to 85°C temperatures and incorporates an option for TEC-less operation. Full characterization data sets including mean- variance and noise equivalent irradiance plots are provided with each camera.

Yes, we retrofit legacy systems (e.g., GE Frame 5, Siemens V94.2) with modern digital controllers, typically completing hardware integration within 4-8 weeks. Software migration requires additional validation time.

We recommend annual performance testing under ISO 3977-2 standards. Critical applications (e.g., offshore platforms) may require semi-annual tests with emissions compliance checks.

All rad-hard devices (e.g., FPGA, ADC) are QML Class V certified under MIL-PRF-38535 and tested to MIL-STD-883 Method 1019 for SEU tolerance. Full qualification reports are available upon request.

Our ASICs and power management ICs operate across -55°C to +175°C ambient temperatures, with derating curves provided in military temperature range (MTR) datasheets.

Our PMA parts (e.g., actuators, sensors) hold FAA/EASA Form 1 certification and match OEM form/fit/function. Installation requires SB/MB documentation per FAA AC 23.1529.

All NAS/MS fasteners include full DNA traceability: melt source (AMS 2301), heat/lot numbers, and AS9100-compliant MTRs with ultrasonic test reports.

AOG orders ship within 4 hours for stocked items (FAA-PMA, EASA Part 21G). Non-stock critical parts trigger priority manufacturing with 72-hour max turnaround.

Gas Turbine

Gas Turbine

Aircraft parts

Aircraft parts