Honeywell’s precision boresight alignment system (PBAS) is a non-optical, gyro-stabilized, computerized system that utilizes navigation-grade inertial technology to capture and calculate boresight alignment corrections with an intuitive, step-by-step guided software that automates all calculations, and provides customized software outputs to match our customers’ requirements.

Boresight alignment is designed to ensure the proper performance of precision equipment across different industries. Depending on the application or platform, the process can be lengthy and expensive, usually having to perform cumbersome equipment setup, data gathering and post processing which can cause disruptions in aerospace or naval ship operations.

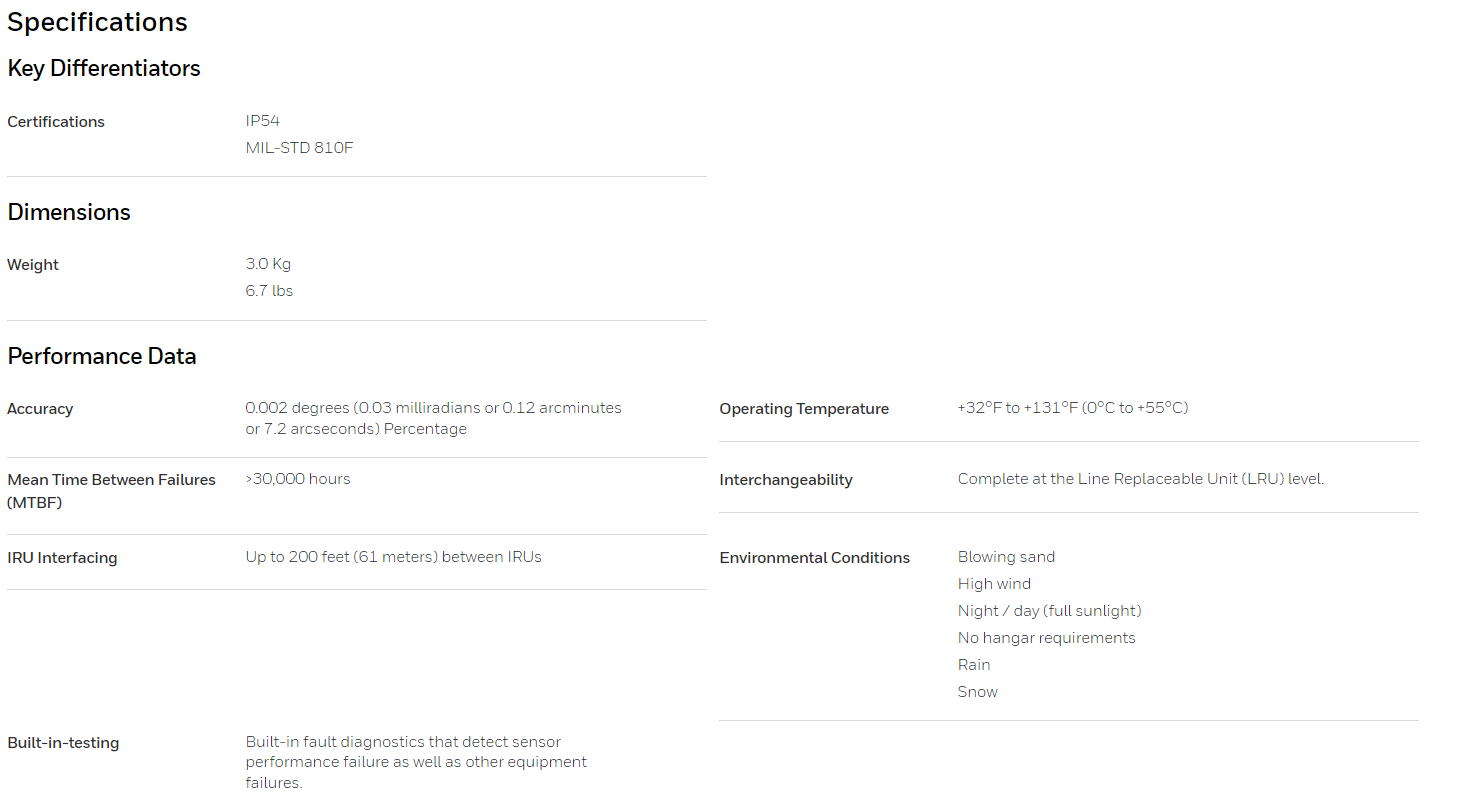

For commercial or defense original equipment manufacturers or maintenance providers that need higher accuracy to align munitions, navigation, radar and sight systems, Honeywell’s precision boresight alignment system (PBAS) step-by-step guided software reduces the need for expert training and job completion time by 50%. We do this by removing the need for periodic calibrations, line of sight, jacking or leveling. As a result, this dramatically decreases maintenance costs and downtime while providing customers with a solution they can trust backed by Honeywell’s century of experience engineering high-performance navigation solutions.

For shipbuilders, surveyors or maintenance providers that need higher accuracy to align munitions, navigation, radar and sight systems, Honeywell’s precision boresight alignment system (PBAS) using step-by-step guided software reduces the need for expert training and cuts job completion time by 50%. We do this by removing the need for line of sight as well as eliminating the need for dry docking by compensating for vessel motion and working without leveling while providing customers with a solution they can trust backed by Honeywell’s century of experience engineering high-performance inertial solutions. PBAS is ideal for naval applications where technicians operate in space-constrained areas because it reduces errors caused by motion, equipment setup time like instrument leveling, measurement time and associated costs by almost 50%, depending on the application.

Yes, we retrofit legacy systems (e.g., GE Frame 5, Siemens V94.2) with modern digital controllers, typically completing hardware integration within 4-8 weeks. Software migration requires additional validation time.

We recommend annual performance testing under ISO 3977-2 standards. Critical applications (e.g., offshore platforms) may require semi-annual tests with emissions compliance checks.

All rad-hard devices (e.g., FPGA, ADC) are QML Class V certified under MIL-PRF-38535 and tested to MIL-STD-883 Method 1019 for SEU tolerance. Full qualification reports are available upon request.

Our ASICs and power management ICs operate across -55°C to +175°C ambient temperatures, with derating curves provided in military temperature range (MTR) datasheets.

Our PMA parts (e.g., actuators, sensors) hold FAA/EASA Form 1 certification and match OEM form/fit/function. Installation requires SB/MB documentation per FAA AC 23.1529.

All NAS/MS fasteners include full DNA traceability: melt source (AMS 2301), heat/lot numbers, and AS9100-compliant MTRs with ultrasonic test reports.

AOG orders ship within 4 hours for stocked items (FAA-PMA, EASA Part 21G). Non-stock critical parts trigger priority manufacturing with 72-hour max turnaround.

Gas Turbine

Gas Turbine

Aircraft parts

Aircraft parts