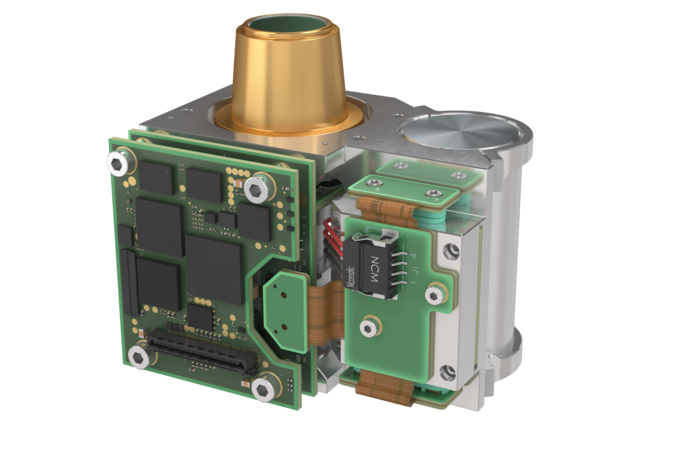

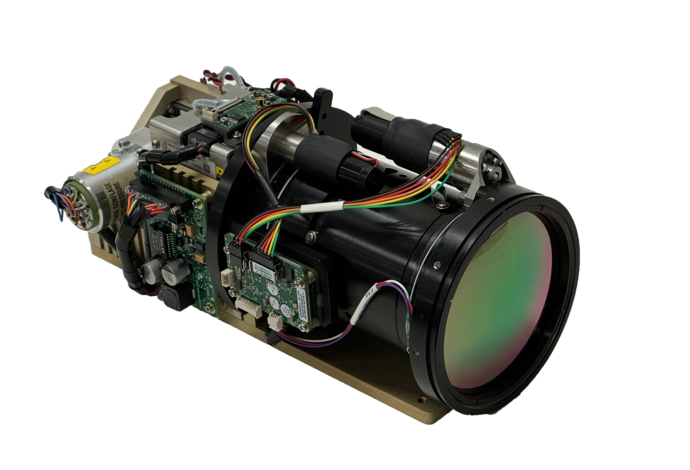

SNAKE SW detectors are very low noise and high speed InGaAs sensors designed for the most demanding SWIR applications from 0.9 to 1.7 μm.

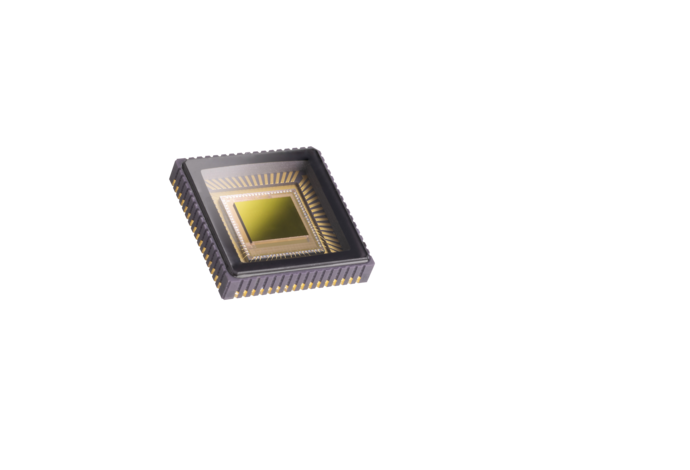

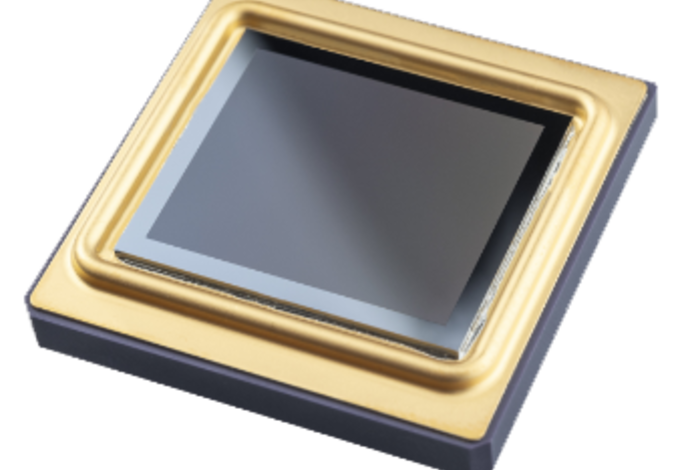

The 640 x 512 VGA format detectors with 15-micron pixels are available in two versions, the SNAKE SW, a hermetically sealed metal package which includes an integral TEC (thermo-electric cooler), or the SNAKE SW TECless, a hermetically sealed ceramic package without a TE Cooler. Both detectors are designed for wavelengths ranging from 0.9µm to 1.7 µm and boast low noise, fast frame rates up to 300Hz, excellent image quality and a pixel operability of >99.9%.

The SWIR detectors are compact, utilize very little power and are cost effective. In particular, the SNAKE SW Tecless has a footprint of only 0.65” x 0.65” and consumes <160mW in 2 output mode.

SNAKE SWs are well-adapted to a large range of applications such as space/LEO communications, (laser beam profiling), surveillance (detection through fog and smoke), hyperspectral imaging and industrial process inspection (agriculture, pharmaceutical, semiconductor,) and scientific R&D.

Lynred InGaAs technology provides outstanding performances in terms of sensitivity, noise, dark current and operability.

Yes, we retrofit legacy systems (e.g., GE Frame 5, Siemens V94.2) with modern digital controllers, typically completing hardware integration within 4-8 weeks. Software migration requires additional validation time.

We recommend annual performance testing under ISO 3977-2 standards. Critical applications (e.g., offshore platforms) may require semi-annual tests with emissions compliance checks.

All rad-hard devices (e.g., FPGA, ADC) are QML Class V certified under MIL-PRF-38535 and tested to MIL-STD-883 Method 1019 for SEU tolerance. Full qualification reports are available upon request.

Our ASICs and power management ICs operate across -55°C to +175°C ambient temperatures, with derating curves provided in military temperature range (MTR) datasheets.

Our PMA parts (e.g., actuators, sensors) hold FAA/EASA Form 1 certification and match OEM form/fit/function. Installation requires SB/MB documentation per FAA AC 23.1529.

All NAS/MS fasteners include full DNA traceability: melt source (AMS 2301), heat/lot numbers, and AS9100-compliant MTRs with ultrasonic test reports.

AOG orders ship within 4 hours for stocked items (FAA-PMA, EASA Part 21G). Non-stock critical parts trigger priority manufacturing with 72-hour max turnaround.

Gas Turbine

Gas Turbine

Aircraft parts

Aircraft parts