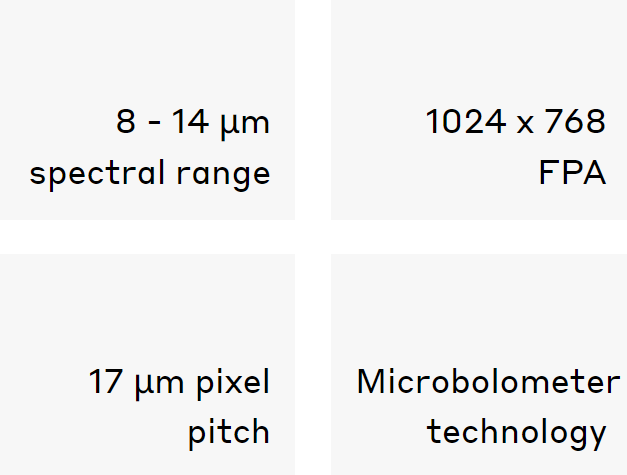

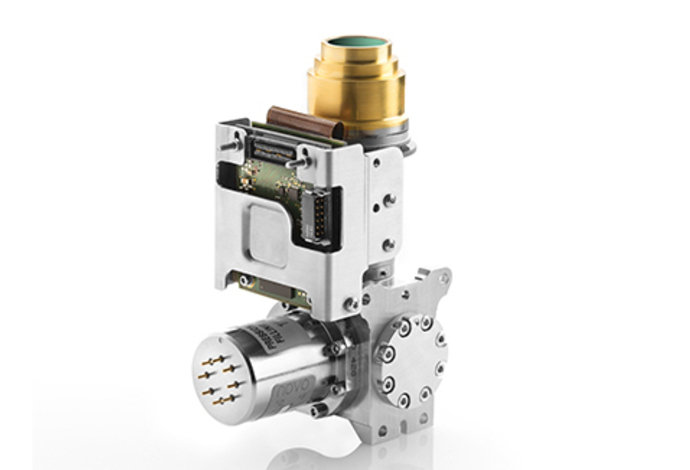

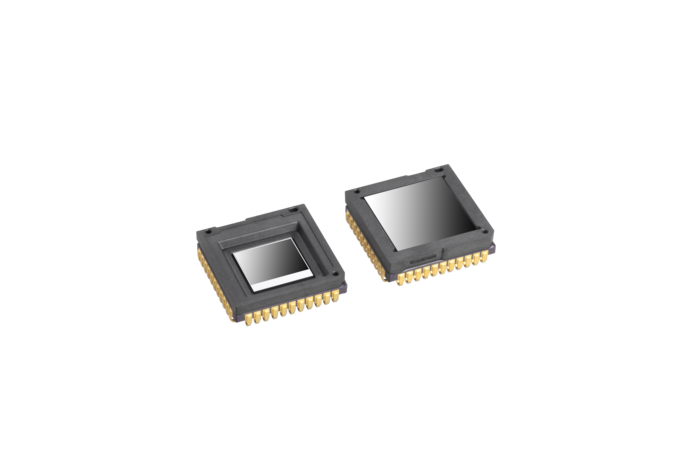

The ATOM 1024 is a full function, high performance, uncooled IR camera core supplied ready to integrate for a variety of demanding applications. It incorporates an advanced Gen2 1024 x 768 microbolometer FPA and delivers clear, high resolution thermal images in an XGA format.

Operating in the LWIR spectral range, the infrared camera core is capable of long-range detection in diverse weather and environmental conditions. Because of its small compact size and low power consumption, rich feature set and industry standard interfaces, the ATOM 1024 is easy to integrate.

The ATOM 1024 is ideally suited for a wide range of applications ranging from UAV airborne mapping and thermography to crticial infrastructure/security surveillance, military tracking, search and rescue and fire control.

The ATOM 1024 is also available as a lab camera for R&D applications that require high resolution thermal imaging performance and includes D*STAR, a desktop Digital Storage, Retrieval and Image Processing Software Suite.

Yes, we retrofit legacy systems (e.g., GE Frame 5, Siemens V94.2) with modern digital controllers, typically completing hardware integration within 4-8 weeks. Software migration requires additional validation time.

We recommend annual performance testing under ISO 3977-2 standards. Critical applications (e.g., offshore platforms) may require semi-annual tests with emissions compliance checks.

All rad-hard devices (e.g., FPGA, ADC) are QML Class V certified under MIL-PRF-38535 and tested to MIL-STD-883 Method 1019 for SEU tolerance. Full qualification reports are available upon request.

Our ASICs and power management ICs operate across -55°C to +175°C ambient temperatures, with derating curves provided in military temperature range (MTR) datasheets.

Our PMA parts (e.g., actuators, sensors) hold FAA/EASA Form 1 certification and match OEM form/fit/function. Installation requires SB/MB documentation per FAA AC 23.1529.

All NAS/MS fasteners include full DNA traceability: melt source (AMS 2301), heat/lot numbers, and AS9100-compliant MTRs with ultrasonic test reports.

AOG orders ship within 4 hours for stocked items (FAA-PMA, EASA Part 21G). Non-stock critical parts trigger priority manufacturing with 72-hour max turnaround.

Gas Turbine

Gas Turbine

Aircraft parts

Aircraft parts