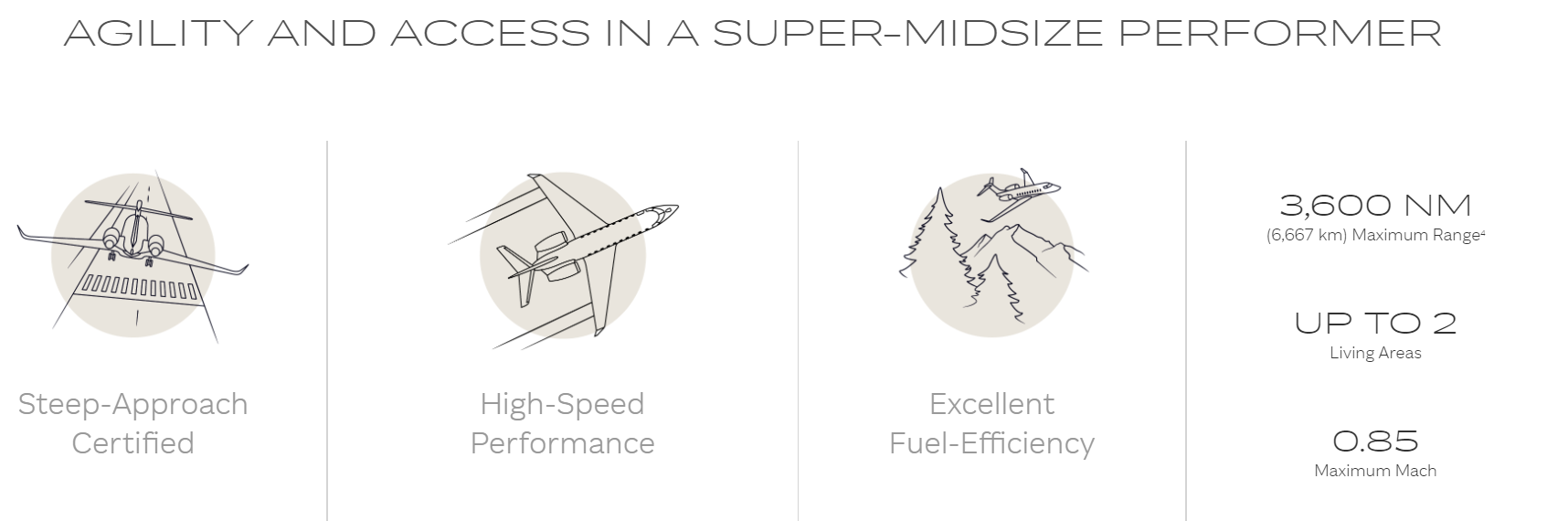

Created to reimagine super-midsize performance, the G280 excels at blazing difficult trails. Certified for steep-approach operations, it makes nimble work of short runways, high-altitude airports and low-visibility conditions.

Seize every moment with a smooth, optimized ride. Paired with high-thrust engines, standard autothrottle and autobrake systems deliver tranquility in flight.

Our skilled artisans create your bespoke interior with premium furniture and accessories, designing your ideal space in the sky. Each configuration supports a fully equipped galley, a generous baggage compartment and an airy lavatory featuring two windows and a full-size closet.

With whisper-quiet engines and sleeping accommodations for up to five passengers, restorative rest is a given.

Arrive refreshed thanks to 100% fresh air and natural light from 19 Gulfstream Large Oval Windows.

Convene and establish your agenda in style, comfortably seating up to 10 passengers in your choice of cabin configurations.

The G280 is primed for fast, efficient flight, with an ideal combination of size, aerodynamic profile, Gulfstream's clean wing, swept winglets and high-thrust Honeywell engines.

Gulfstream is committed to environmentally responsible business practices and the development of new technologies promoting safer, more efficient air travel. We invite you to explore the sustainability innovation story behind our aircraft.

The G280 features the PlaneView280™ flight deck. This industry-leading technology is designed to augment situational awareness, reduce workload and boost pilot efficiency.

Our Enhanced Flight Vision System (EFVS) allows authorized pilots to land without natural vision in low-visibility conditions, increasing access to airports and reducing go-arounds. A Synthetic Vision-Primary Flight Display, featuring 3D graphics of terrain and runways, further boosts pilots’ situational awareness.

Yes, we retrofit legacy systems (e.g., GE Frame 5, Siemens V94.2) with modern digital controllers, typically completing hardware integration within 4-8 weeks. Software migration requires additional validation time.

We recommend annual performance testing under ISO 3977-2 standards. Critical applications (e.g., offshore platforms) may require semi-annual tests with emissions compliance checks.

All rad-hard devices (e.g., FPGA, ADC) are QML Class V certified under MIL-PRF-38535 and tested to MIL-STD-883 Method 1019 for SEU tolerance. Full qualification reports are available upon request.

Our ASICs and power management ICs operate across -55°C to +175°C ambient temperatures, with derating curves provided in military temperature range (MTR) datasheets.

Our PMA parts (e.g., actuators, sensors) hold FAA/EASA Form 1 certification and match OEM form/fit/function. Installation requires SB/MB documentation per FAA AC 23.1529.

All NAS/MS fasteners include full DNA traceability: melt source (AMS 2301), heat/lot numbers, and AS9100-compliant MTRs with ultrasonic test reports.

AOG orders ship within 4 hours for stocked items (FAA-PMA, EASA Part 21G). Non-stock critical parts trigger priority manufacturing with 72-hour max turnaround.

Gas Turbine

Gas Turbine

Aircraft parts

Aircraft parts