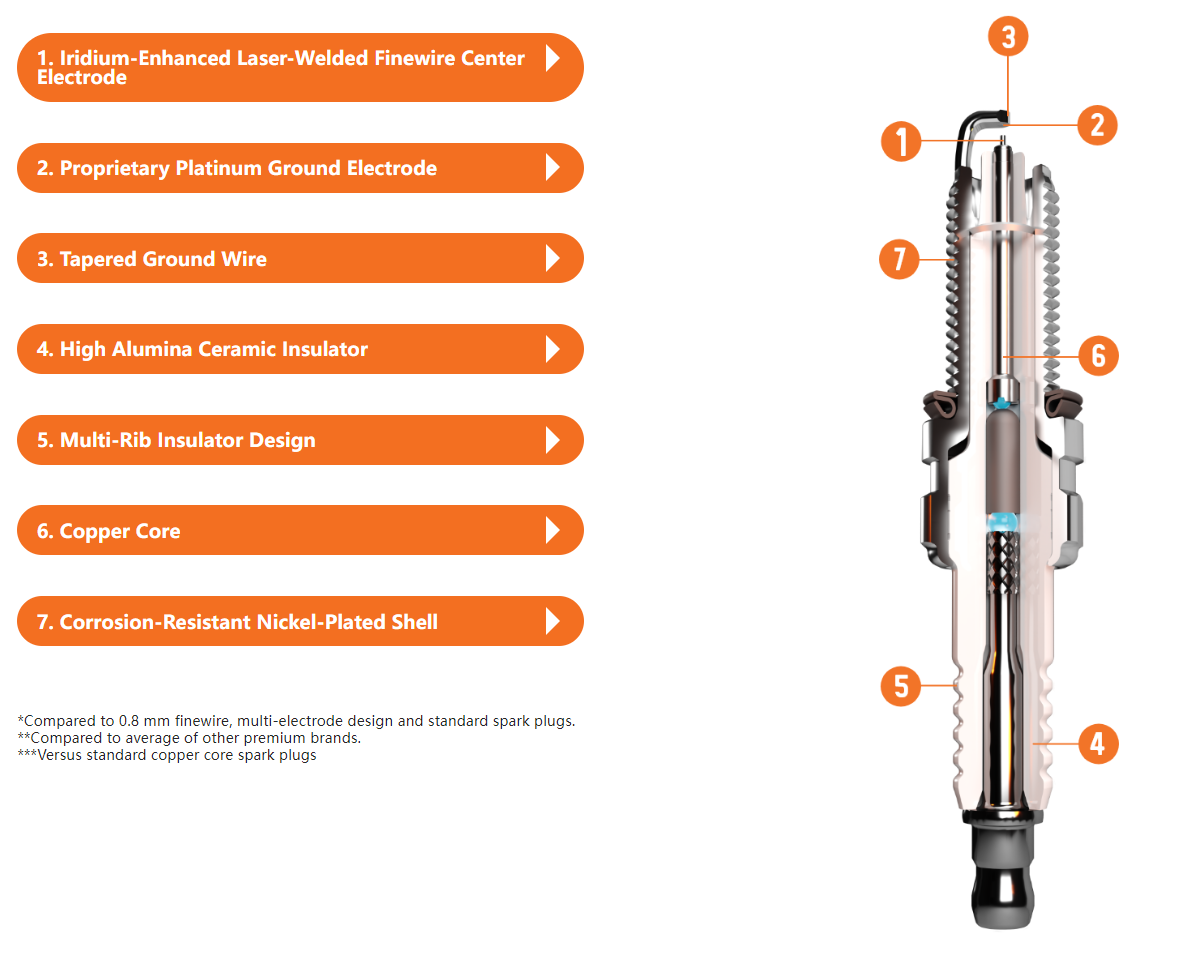

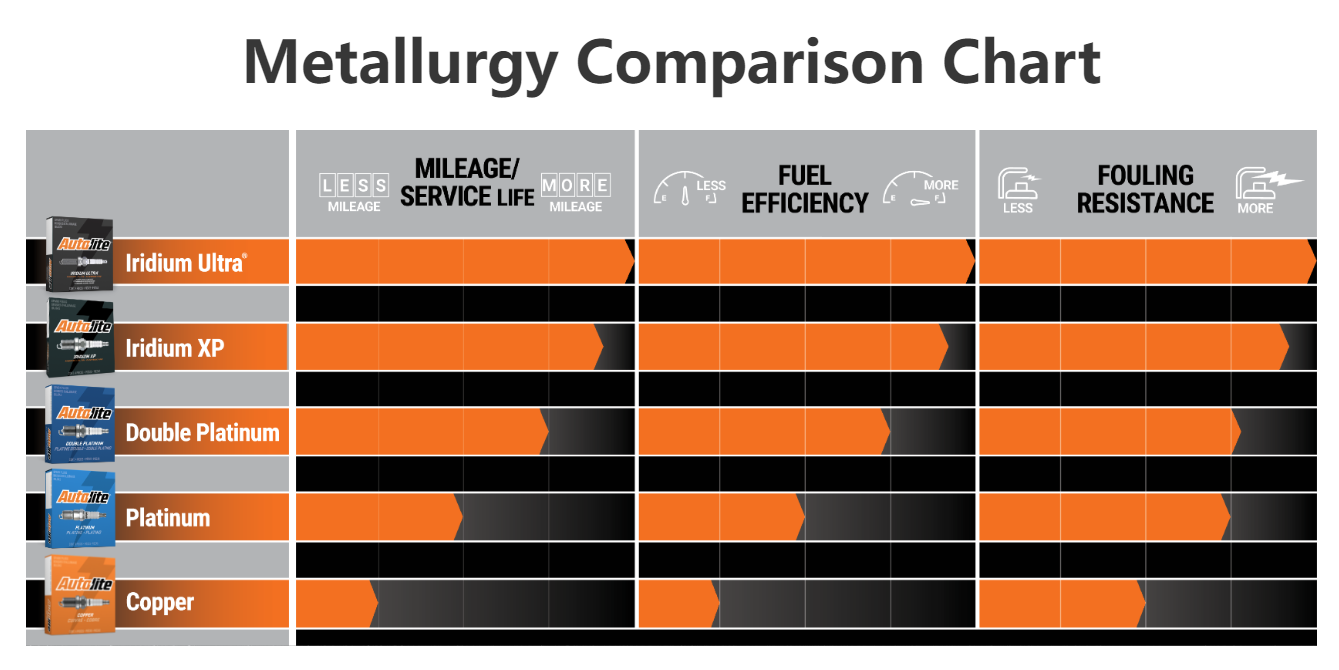

Advanced engines need advanced technology, which is why we have engineered a premium spark plug that can meet the critical demands of late model engines. Iridium Ultra® is equipped with a laser-welded iridium-enhanced finewire center electrode that ensures your engine runs at maximum performance; while its double precious metal design provides increased durability*, allowing your engine to maintain desired performance levels for longer. Iridium Ultra® delivers optimal fuel efficiency, acceleration, and ignitability**, making it the best OE replacement plug choice for modern engines.

Replacing spark plugs can be a simple job, if you take things one step at a time. Here's a general guide to the proper procedures.

Read the entire process first!

Gather needed tools and parts - a set of Autolite spark plugs, a ratchet, a spark plug socket (make sure you have the right size), extensions, a gapping tool, and dielectric grease. Other hand tools may be needed on some vehicles.

Remove spark plug wires or coils. Grasp the plug wire boot and twist it about one-quarter turn to loosen the seal, and then pull straight off. Stubborn boots may require using plug wire boot pliers. Number plug wires with tape as you remove them to avoid crossing them, or only disconnect one at a time. If your vehicle is coil-on-plug, disconnect the coil connectors, remove the hold-down bolts, and remove the coils.

Before loosening each spark plug, clean dirt or fluids out of the plug seat area with a blast of compressed air, a shop vacuum, or by blowing around the spark plug through a soda straw. This prevents contaminants from falling into combustion chamber when the old plugs are removed.

Remove plugs and line them up in cylinder order. A thorough visual inspection of the plugs can identify problems that may need correction or show you they are all good. Autolite publishes a plug tip inspection guide with more information.

Gap new plugs as recommended in owner's manual or Autolite Spark Plug Catalog. Use a gapping tool gauge to measure the gap between the center and ground electrode. The gauge should pass through snugly but easily. If too loose or tight, use the gapping tool to correct the gap.

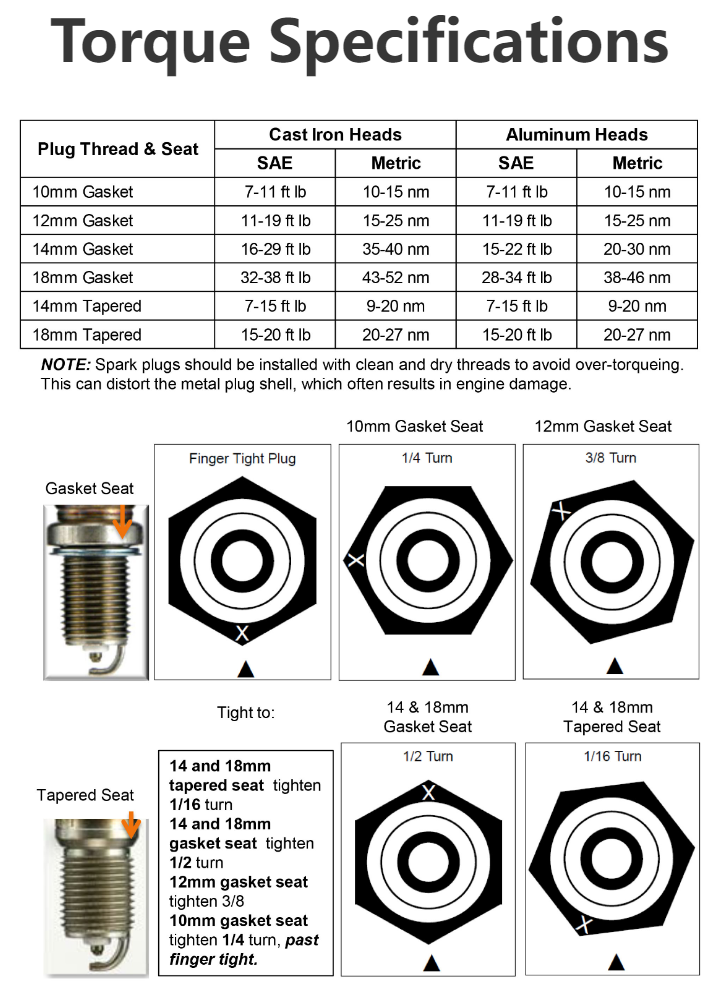

Screw new plugs in by hand until tight. If a plug tightens up too soon while turning them in by hand, use a thread chaser to clean the threads. Use a torque wrench to tighten spark plugs following manufacturer’s recommendations, or refer to the torque chart in the Autolite Spark Plug Catalog if you don’t have a torque wrench.

Inspect the plug wires and boots (or the coils and boots on coil-on-plug systems) for brittleness or cracking, and check for corrosion onthe plug terminals inside each boot. Replace suspect coils, boots and or wires as needed. Lubricate the plug contact area inside each boot with Dielectric Grease and then reinstall the plug wires (or coils and boots) making sure they are installed in the correct order and fastened securely.

Verify your repair by starting the engine. Misfires or a rough idle can mean the wires are in the wrong order or loose. Recheck firing order and coil connections closely if the engine still isn't running right.

Yes, we retrofit legacy systems (e.g., GE Frame 5, Siemens V94.2) with modern digital controllers, typically completing hardware integration within 4-8 weeks. Software migration requires additional validation time.

We recommend annual performance testing under ISO 3977-2 standards. Critical applications (e.g., offshore platforms) may require semi-annual tests with emissions compliance checks.

All rad-hard devices (e.g., FPGA, ADC) are QML Class V certified under MIL-PRF-38535 and tested to MIL-STD-883 Method 1019 for SEU tolerance. Full qualification reports are available upon request.

Our ASICs and power management ICs operate across -55°C to +175°C ambient temperatures, with derating curves provided in military temperature range (MTR) datasheets.

Our PMA parts (e.g., actuators, sensors) hold FAA/EASA Form 1 certification and match OEM form/fit/function. Installation requires SB/MB documentation per FAA AC 23.1529.

All NAS/MS fasteners include full DNA traceability: melt source (AMS 2301), heat/lot numbers, and AS9100-compliant MTRs with ultrasonic test reports.

AOG orders ship within 4 hours for stocked items (FAA-PMA, EASA Part 21G). Non-stock critical parts trigger priority manufacturing with 72-hour max turnaround.

Gas Turbine

Gas Turbine

Aircraft parts

Aircraft parts